Scale Inhibitor Chemicals for Cooling Water Systems

Environmental restrictions on discharge, escalating water costs, and water scarcity are causing many companies to conserve more water in recirculating cooling towers.

Industrial facilities are tightening up their systems to run high cycles of concentration with minimal or no blowdown. Many sites use gray waters containing higher levels of impurities.

As the water evaporates across the cooling tower, pure water vapor is lost, and the dissolved minerals and other impurities are concentrated in the remaining water. If concentration cycles are increased too far, the solubilities of various minerals exceed their saturation and form deposits, often in the cooling tower fill and in hotter areas such as heat exchangers.

The Dangers of Unwanted Deposition

A major cause of industrial water system failures is the deposition of unwanted materials on equipment surfaces. Deposits can cause system performance reduction and unexpected shutdowns, environmentally challenging cleaning operations, and associated costs.

Deposits consist of six general types:

- Crystalline or amorphous mineral scales (e.g., calcium carbonate, calcium sulfate, calcium phosphate, amorphous silica, and metal silicates)

- Fouling caused by suspended solids (e.g., mud and silt in the makeup water and airborne dust)

- Transient corrosion products such as iron oxides and hydroxides

- Microbiological deposits

- Process contamination such as hydrocarbon leaks

- Fouling related to corrosion inhibitors such as calcium phosphate, zinc phosphate, and zinc hydroxide

Common Cooling System Scales

- Calcium carbonate (CaCO3)

- Calcium sulfate (CaSO4)

- Calcium phosphate (Ca3(PO4)2)

- Magnesium silicate (MgSiO3)

- Aluminum silicate (Al2O3·SiO3)

- Zinc phosphate (Zn3(PO4)2)

- Iron phosphate (FePO4)

- Calcium magnesium silicate (CaO·MgO·2SiO2)

- Silica (SiO2)

Using Cooling Tower Scale Inhibitors to Prevent Deposition

Dispersant or antifoulant scale inhibitors can help prevent the agglomeration of solids and their accumulation on critical surfaces. Materials that handle these potential deposits have been referred to in the industry as dispersants, deposit control agents, or scale inhibitors. Deposit control falls into one of three categories: inhibition, distortion, and dispersion. ChemTreat has a full product line of scale inhibitors to control deposition and fouling, including polyphosphates, organic phosphates, polymers, polyelectrolytes, and surfactants.

Polyphosphates

Polyphosphates contain multiple phosphorus atoms connected to each other through an oxygen bridge. The inorganic phosphate polymer generally contains from 3 to 15 units. Polyphosphates contain negatively charged oxygen atoms that attract positively charged cations such as calcium, iron, etc. This attraction can effectively sequester (combine) with the cations, forming a complex that interferes with deposit formation. A threshold concentration must be reached before the polyphosphates can prevent calcium carbonate scaling at concentrations with low supersaturation levels. In the same way, polyphosphate combines with iron and manganese to prevent red and black stains, respectively. Polyphosphate effectiveness is limited by reversion to orthophosphate under certain operating conditions.

Organophosphate

Phosphonate scale inhibitors work by being adsorbed onto active particle growth sites, where they retard the nucleation and crystal growth rate. Phosphonates are sequestrants that form a complex with various cations and keep water solutions stable even at points of relatively high supersaturation. A few examples of organophosphate scale inhibitors commonly used in cooling systems include:

- 1-hydroxyethylidene 1,1-diphosphonic acid (HEDP)

- 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTC)

Amino phosphonate scale inhibitors include:

- Diethylenetriamine penta (methylene phosphonic acid) (DETPMP)

- Amino trimethylene phosphonic acid (ATMP)

Polymers

Polymer research shows that certain functional groups like carboxylate and sulfonate are capable of inhibiting scale formation. These types of polymers may be effective in controlling various types of scales, depending on the types of monomers present in the polymer. Polymers interfere with crystal lattice growth in mineral scale formations and prevent or reverse the growth of dense, adherent mineral deposits.

Some examples of polymers include:

- Polyacrylic acid polymers

- Polymaleic acid polymers

- Co-polymers and multi-polymers containing various functional groups such as acrylic acid, hydroxypropyl acrylate (HPA), 2-acrylamido-2-methylpropane sulfonic acid (AMPS), ter-butyl acrylate (TBA), sulfonated styrene (SS), etc.

- Advanced polymers such as ChemTreat Quadrasperse® and FlexSperse®

- Tagged polymers such as QuadDetect™

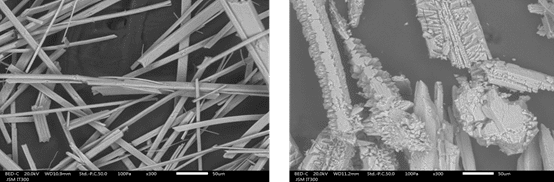

Polymers also function by modifying or distorting newly formed scale crystals. These distorted crystals re-dissolve in the water and do not form scales on critical equipment. As shown below, distorted crystals exhibit none of the needle-like or flat-faced crystals shown without polymeric scale inhibitors, plus the structure is much more fragile, friable, and does not build large crystal grains.

Using Surfactants (Surface-Active Agents) to Control Deposition and Fouling

One factor in removing or controlling deposition or fouling can be the inability of the polymers to penetrate the deposit. This is especially true of any organics, oils, and greases that get into the system. These materials can bind the deposits together, preventing them from being dispersed. Biofilm is an especially problematic strong binder.

To remove these materials, water may need some assistance from surface-active agents or surfactants. Surfactants are classified as anionic, cationic, and nonionic. Nonionic surfactants are typically used for removing oil and grease deposits. Nonionic surfactants are also preferred because of low interaction with charged dispersants and coagulants, as well as their generally low foaming tendency and aquatic effects.

ChemTreat’s expert technical staff work with our experienced water treatment specialists to solve our customers’ water treatment challenges. Contact us today to schedule a consultation.

Learn more about cooling treatment: