The Problem

A Midwestern ammonia plant uses three makeup water sources, including city water and tertiary recycled water (treated effluent from the city). The tertiary water contains phosphate, the discharge of which is limited by regulatory bodies.

Since the city water typically does not contain phosphate, switching back and forth between city and tertiary water caused severe corrosion and scaling issues.

The Solution

To help the facility reduce the amount of phosphate it discharges to the environment, ChemTreat switched the cooling treatment at the plant from a phosphate-based program to FlexPro® non-phosphate technology. FlexPro not only provides excellent corrosion protection for cooling systems, but also reduces the amount of phosphate discharged to the environment, helping prevent harmful algal bloom growth.

When phosphate levels in the city water makeup suddenly increased to five times their usual concentration, the ChemTreat team also coordinated the quick installation of a rental dissolved air flotation (DAF) system to remove phosphate from the reverse osmosis (RO) reject.

Biofouling in the customer’s pretreatment system was additionally reduced after cleaning the pipes with ChemTreat CL457 solution and high-pH RL5000 to boost conductivity.

The Results

Using non-phosphate treatment helped the facility control corrosion and scaling issues more easily than using an incumbent supplier’s phosphate program. Reducing phosphate discharge is critical for this facility to comply with effluent discharge regulations. The facility curtails production to meet the discharge limits, so stabilizing the treatment program improved plant productivity while protecting their assets.

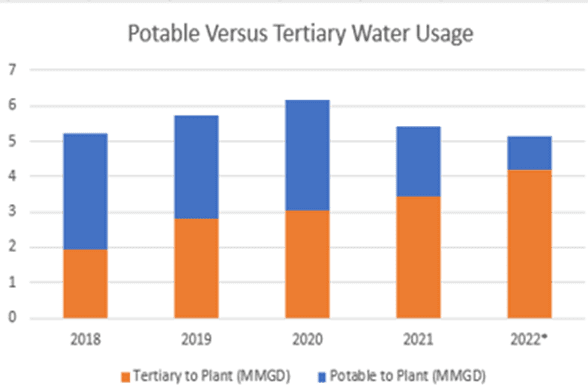

The improvements to the pretreatment system implemented by ChemTreat and the customer allowed the plant to increase tertiary water usage by approximately 20%. This equates to around 315 million more gallons of tertiary recycle water used per year, saving the customer $2.5 million annually in city water makeup cost and reducing the demand for city water from the potable stream.

Chart showing the reduction of potable water being used since the ChemTreat program was adopted

Environmental Stewardship

The company running this ammonia plant has a number of environmental priorities, including a focus on water stewardship. By increasing tertiary water usage and reducing phosphate discharge to the environment, the facility is able to contribute to these goals.

Download the Case StudyResults are examples only. They are not guaranteed. Actual results may vary.