-

USA - English

- Locations

- SDS Access

- CTVista®+ Login

A refinery in the Midwest operates a direct flare gas system without a recovery unit.

Historically, they steam-atomized MEA triazine-based scavengers into the flare line to comply with the three-hour rolling average limit of 162 ppm hydrogen sulfide (H2S). Not only was this a costly treatment, but it failed to bring the system into compliance at times during operational upsets with high H2S spikes.

Looking to reduce costs and maintain reliable compliance, the facility decided to partner with ChemTreat’s experienced refining team to find an alternate solution.

ChemTreat recommended a novel patent-pending approach to help improve performance and reduce costs. A customized injection system was installed to allow atomization of ChemTreat’s proprietary non-nitrogen chemistry CT9156 into the flare line without steam.

With proper atomization, this chemistry works at a lower sub-stoichiometric dosage requirement compared to triazine, greatly reducing treatment costs.

CT9156 functions by converting H2S to non-reversible water-soluble compounds by using a catalyst to accelerate subsequent reactions. In comparative trials, CT9156 has consistently exhibited a faster reaction time than triazine.

By eliminating MEA and amine from the treatment chemistry, CT9156 does not contribute reaction byproducts that can inhibit wastewater treatment system performance. This also reduces process salting and corrosion issues when flare gas residual is sent to the slop oil system or when wastewater treatment plant effluent is reused in other plant processes.

After applying this proprietary treatment, the refinery immediately saw H2S concentrations to the flare drop well below the permit compliance limit during multiple upset episodes.

The facility has additionally reduced corrosion concerns in the flare system, and nitrogen levels in the wastewater treatment plant inlet have decreased.

After the success of the trial, the refinery plans to implement this new atomization injection system in two additional flare locations, realizing potential savings of over $400,000 in annual H2S treatments costs.

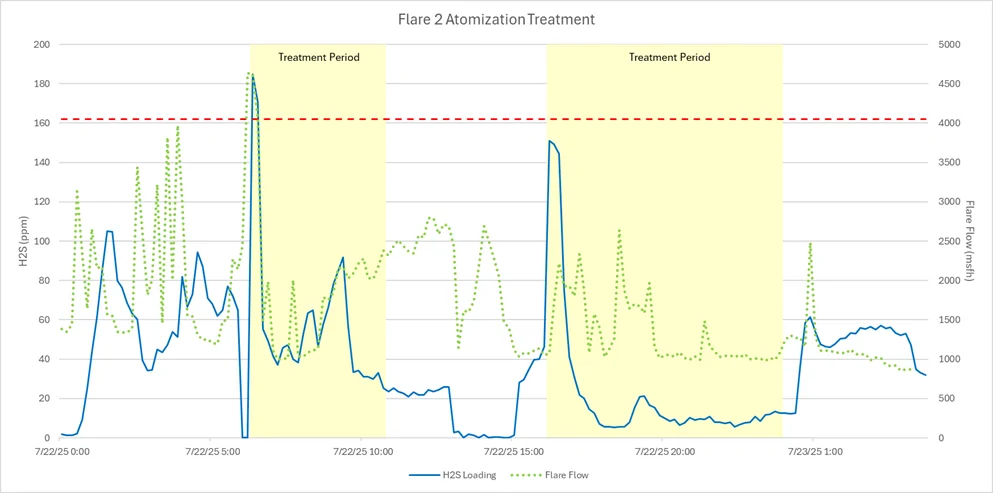

Initial trial results showing immediate reduction in H2S levels, keeping the three-hour rolling average below the 162 ppm compliance limit.

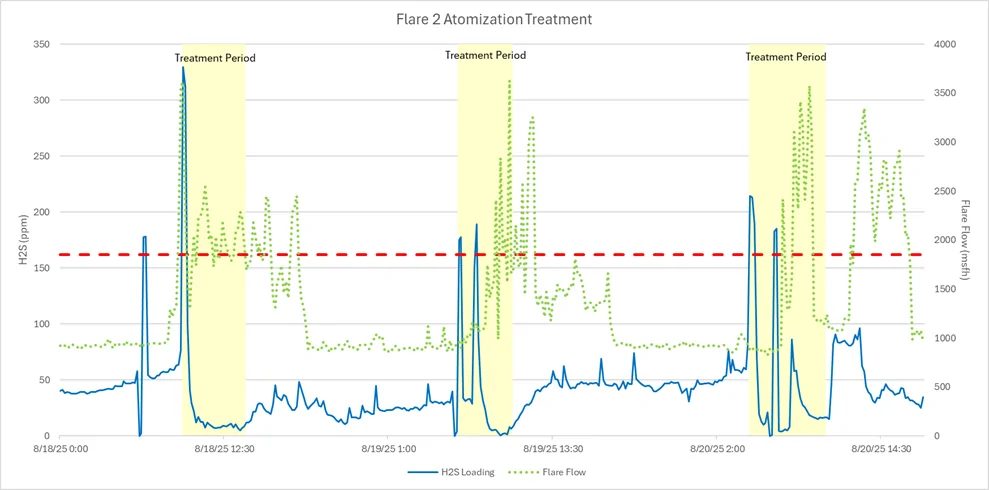

Additional periods of treatment verifying immediate reductions in H2S levels below permit levels during significantly elevated flare gas rates.

Download the Case StudyResults are examples only. They are not guaranteed. Actual results may vary.