-

USA - English

- Locations

- SDS Access

- CTVista®+ Login

During a planned turnaround, a refinery in the Midwest experienced significant hydrogen sulfide (H2S) load in the flare while the flare gas recovery unit (FGRU) was out of service.

The facility historically purged the system with natural gas, but during high H2S excursions, operators were consistently unable to maintain the three-hour average loadings below the permit target of 162 ppm. During FGRU outages, H2S rose to levels as high as 1.5–2.0% (15,000–20,000 ppm).

Refinery personnel considered using MEA triazine despite anticipated high treatment costs. However, triazine would not be able to reliably reduce H2S below the analyzer detection limit of 300 ppm until the FGRU was back in service for an extended period.

Instead, the refinery asked ChemTreat to develop a treatment program to help the facility maintain H2S levels below target and alleviate environmental exceedances that may lead to fines and reduced profitability.

ChemTreat’s field engineers devised a two-phased approach to provide an immediate resolution to the issue as well as enhance the permanent scavenger injection application.

The ChemTreat team selected CT9156, a proprietary, non-nitrogen scavenger for treatment.

Comparative trials have shown that CT9156 provides several advantages over traditional MEA triazine treatment:

MEA triazine additionally creates reaction byproducts that can inhibit microbial activity in wastewater treatment systems and overload biotreaters. Implementing CT9156 will help facilities avoid these potential issues.

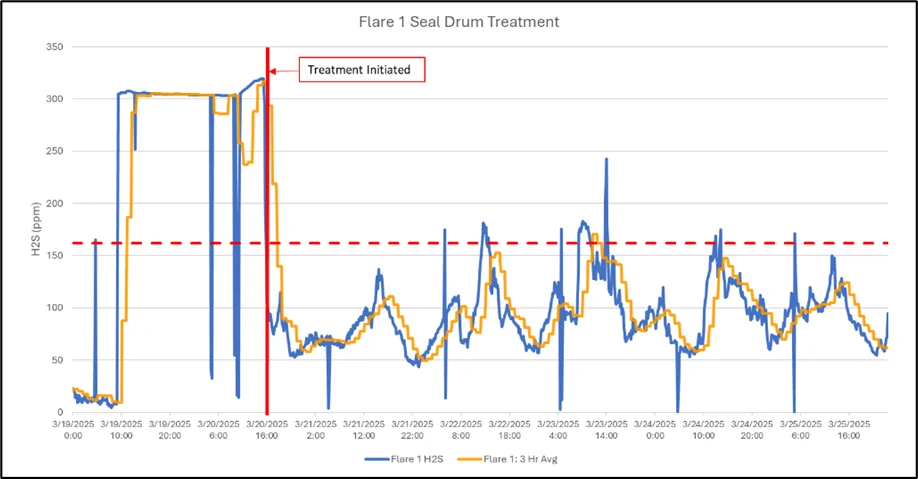

When the FGRU outage began, the H2S in the flare instantly exceeded the upper limits of the analyzer. ChemTreat worked with the refinery’s engineers and operators to treat the seal drum water with CT9156. H2S levels rapidly dropped and stayed below the three-hour target of 162 ppm.

H2S levels were rapidly reduced in the flare 1 steam drum after CT9156 treatment was applied.

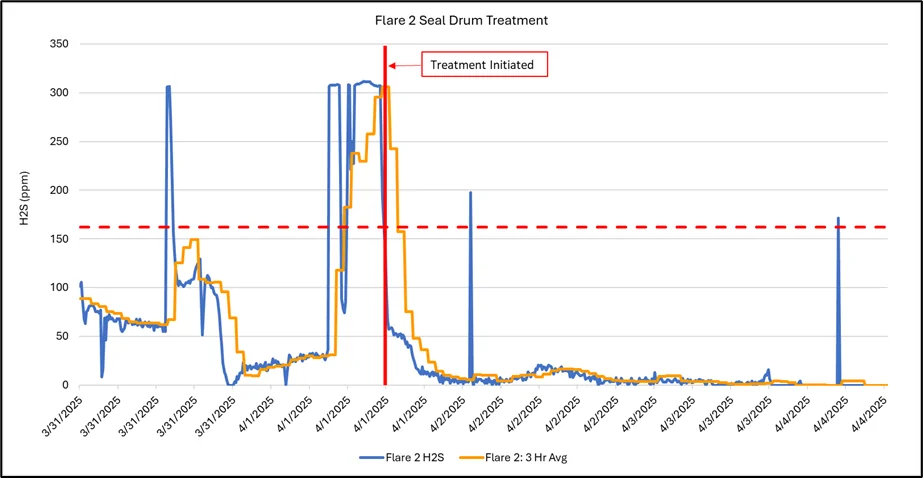

When the second flare system was brought back on-line, operators again struggled to meet permit limits. CT9156 was applied to this seal drum as well, and H2S levels were reduced to well below the three-hour 162 ppm limit.

The flare 2 seal drum also saw a rapid reduction in H2S load after CT9156 treatment.

In parallel with the turnaround treatment program, ChemTreat partnered with equipment providers to engineer a scavenger atomization system using high-pressure pumps and injection nozzles designed for variable H2S loadings and treatment demands. The goal of this treatment strategy was optimizing scavenger demand to control costs and improve system reliability.

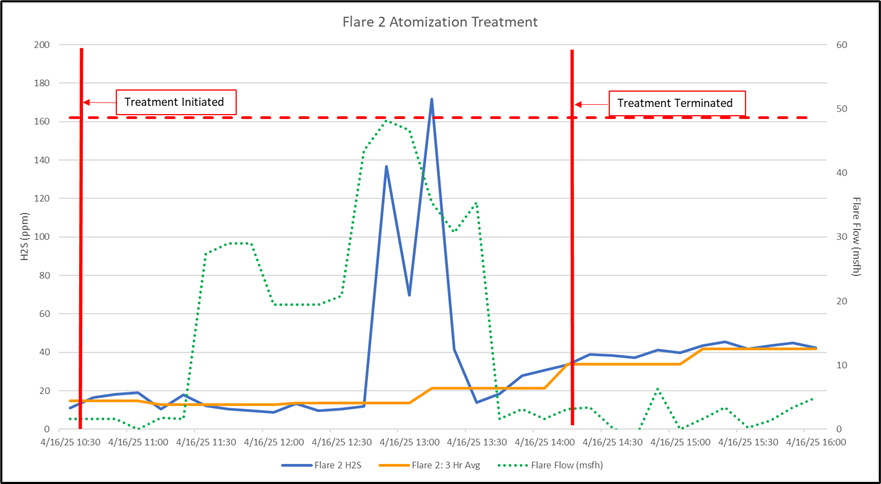

After the program was developed, the refinery took the FGRU off-line for a live flare job. To test the new injection system, the scavenger was proactively atomized into the flare line to reduce the potential for environmental permit exceedance.

With an incoming H2S load of approximately 2%, the CT9156 treatment program successfully maintained H2S in the flare below the three-hour limit of 162 ppm. The load averaged at 44 ppm during the outage.

Even when the gas flow spiked to nearly 50,000 standard cubic feet (MSCFH), CT9156 treatment successfully maintained target compliance.

With CT9156 treatment, the FGRU maintained H2S levels within the target range during a live flare job.

Thanks to the success of the CT9156 treatment under extreme outage conditions, the refinery decided to fully implement ChemTreat’s treatment strategy to improve reliable H2S environmental compliance.

Applying CT9156 treatment for H2S management in FGRU systems offers multiple advantages over traditional MEA triazine treatment, including: