-

USA - English

- Locations

- SDS Access

- CTVista®+ Login

A large steel mill in the southern United States experienced persistent microbiological fouling and corrosion within its 2-million-gallon laminar contact cooling water system.

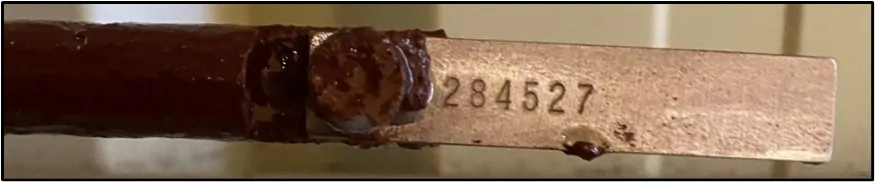

In contact cooling systems, biofilm formation can trap solids, grease, oils, and other contaminants on heat transfer and system surfaces. This accumulation reduces cooling efficiency and promotes anaerobic conditions, accelerating microbiologically influenced corrosion (MIC). MIC can negatively impact system reliability, shorten asset life, and indirectly affect product quality.

In this application, laminar water comes into direct contact with steel coils, introducing iron fines, oils, and other process contaminants into the cooling system. Solids are removed in settling basins, where material accumulates before periodic mechanical removal. These basins can become significant sources of microbial growth due to increased nutrient availability and biological inoculation, further increasing microbial demand throughout the system.

Collectively, these operating conditions made effective biological control challenging. Upset conditions frequently resulted in rapid microbial proliferation, often requiring aggressive biocide treatment. As a result, fouling and corrosion control proved difficult under a traditional bleach and bromine treatment program. To address these challenges, the mill partnered with ChemTreat to evaluate and implement an alternative treatment strategy.

To evaluate improved performance and cost efficiency, the mill decided to trial ChemTreat’s SurfClean™ 2.0 as a substitute for bromine treatment. Switching to this dual-purpose halogen stabilizer and biodispersant required no changes to the existing dosing equipment.

Prior to the trial, bleach consumption averaged 20–40 gallons per day to maintain 0.2–0.3 ppm of free chlorine. Bromine was fed at a 1:4–1:6 ratio, adjusted seasonally.

During the trial, bleach was fed continuously at a very low rate, maintaining 0.04–0.08 ppm free chlorine. SurfClean 2.0 was fed at an average of 3–5 gallons per day. With this treatment approach, the facility was able to reduce bleach feed by over 70%, to an average of 9 gallons per day.

Within days of implementing SurfClean 2.0, biofilm accumulation on system surfaces visibly decreased. The reduced bleach feed, lower free chlorine residuals, and corresponding reduction in chloride concentration significantly lowered the system’s corrosion potential. The improvement in surface cleanliness also reduced the risk of MIC.

Unlike the previous treatment program, SurfClean 2.0 helped the facility manage biological growth even during upset conditions.

SurfClean 2.0 significantly improved stability and performance in the steel mill’s laminar contact system:

Following the success of the trial, the steel mill permanently adopted SurfClean 2.0 in the laminar contact system and converted all other on-site cooling tower systems to this program.

These improvements resulted in:

Results are examples only. They are not guaranteed. Actual results may vary.