-

USA - English

- Locations

- SDS Access

- CTVista®+ Login

A medical center was using manual adjustments for conductivity control after an old controller failed, causing them to over- or under-cycle their boilers. They needed to increase control to preserve and maintain their boiler assets, increase cycles of concentration, and achieve their water savings goals.

ChemTreat helped the facility install a boiler controller and connected it to their CTVista+ software to increase boiler conductivity control and cycles of concentration. CTVista+ provided real-time monitoring of the boiler system.

With the new boiler controller and CTVista+ setup, the customer was able to:

Calculated saving from this project:

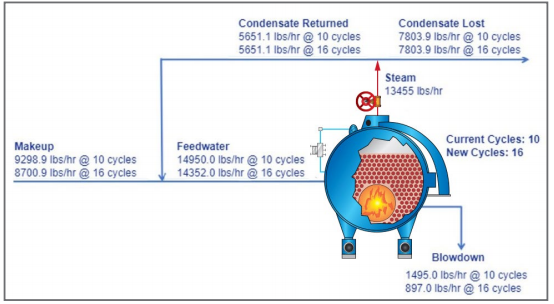

This firetube boiler mass balance diagram, generated within CTVista+, shows the water savings associated with increasing cycles of concentration from 10 to 16.

Neutralized conductivity trend chart generated by CTVista+ to monitor performance. The green spectrum indicates the range of desired conductivity. The yellow arrow indicates when the new controller was installed.

Want to learn more about CTVista+ and intelligent industrial water management? Click here.

Features such as 24/7 surveillance and alarming may come at additional cost and may not be available at all sites.