Intelligent Water Management

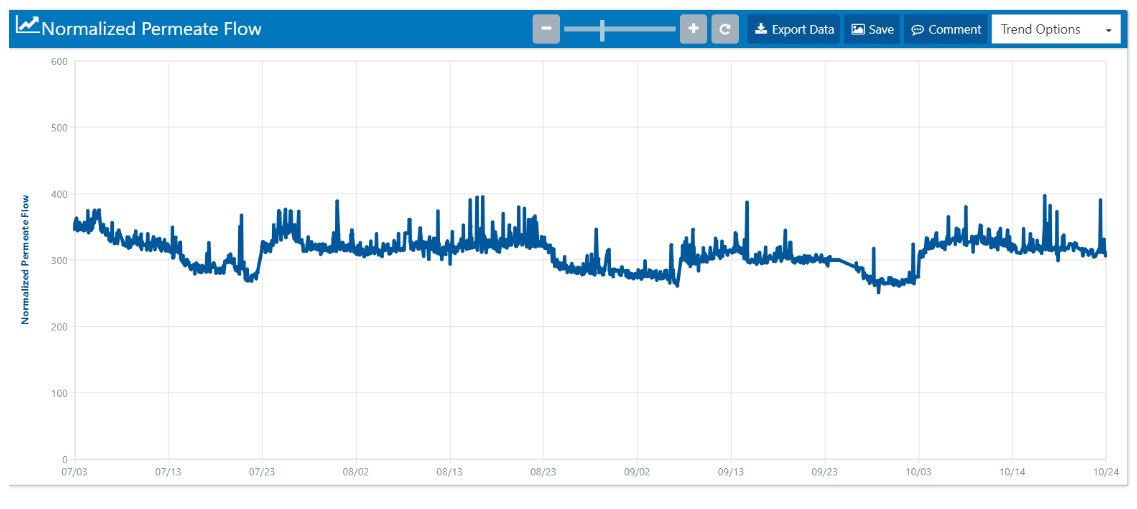

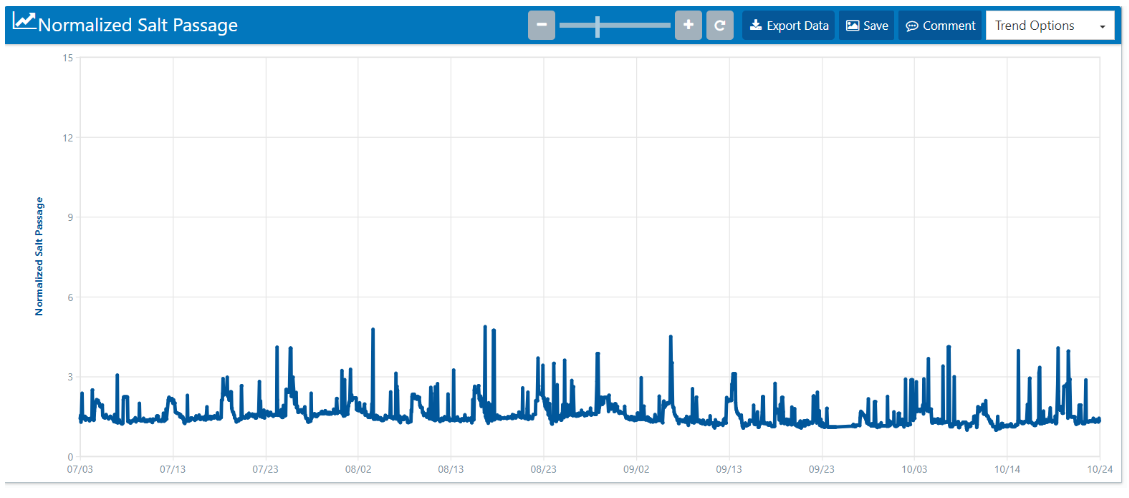

Our CTVista®+ intelligent water management platform enables monitoring and control of your water treatment programs by providing data management, analytics, reporting, and real-time guidance.

This cloud-based software helps our customers make real-time, data-driven decisions to:

- Protect system assets

- Minimize water, chemical, and energy costs

- Meet sustainability goals

CTVista+ combines the collective wisdom of experienced water treatment professionals with real-time data to optimize the effectiveness of the chemical treatment program at your beverage manufacturing facility.

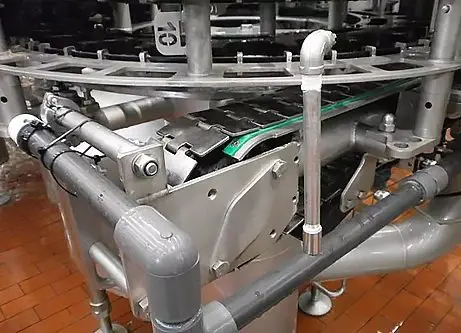

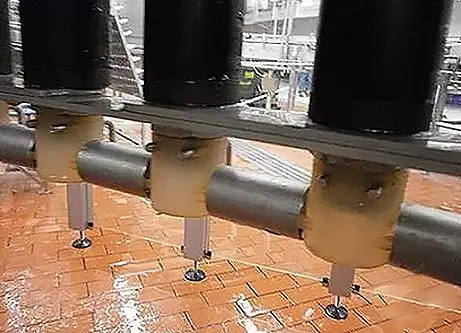

Compatible with most industry-standard equipment setups, CTVista+ is easy to integrate with your existing equipment. Our team can also work with you to create and install a custom equipment package best-suited to your facility’s needs.

Beverage Manufacturing Water Treatment

Beverage Manufacturing Water Treatment