-

USA - English

- Locations

- SDS Access

- CTVista®+ Login

Water treatment is a core component of a successfully run nitrogen or syngas facility. Cooling, boiler, and steam systems at these facilities need to run at peak efficiency to maintain production standards.

ChemTreat’s experienced team works closely with our customers producing nitrogen and syngas to understand their water treatment needs and help them implement programs to improve operational efficiency, protect critical assets, reduce costs, and meet environmental goals.

Our highly experienced application experts and local water treatment specialists can provide a wide array of treatment solutions for your utility systems.

ChemTreat offers a full line of boiler water treatment chemicals, testing, and control equipment. Our programs can help you increase system efficiency, decrease plant downtime and maintenance costs, and extend equipment life.

Our cooling treatment programs start with an assessment of your process, water chemistry, cooling requirements, and cooling system metallurgy. This allows us to understand your system needs and develop a custom program to help you reduce corrosion, scale, and/or fouling issues.

Applying our products can help you keep your system running at peak efficiency, extend equipment life and reduce water usage.

We also offer state-of-the-art control and water monitoring technology with DCS compatibility to help increase reliability and decrease costs.

FlexPro®: A Breakthrough Innovation for Cooling System Treatment

FlexPro®: A Breakthrough Innovation for Cooling System TreatmentChemTreat’s FlexPro® product line includes a wide range of treatment options for corrosive, scaling, and reclaim waters. Many FlexPro products do not contain phosphates or zinc, helping facilities meet environmental goals while improving the efficiency of their cooling systems.

Benefits of FlexPro® over industry-standard phosphate scale and corrosion inhibitor programs include:

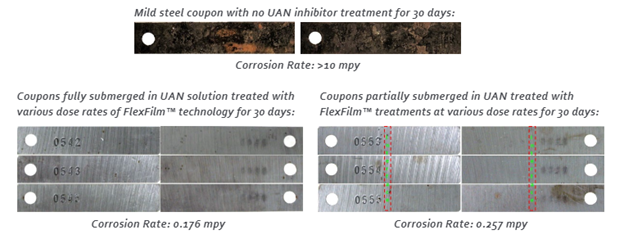

Urea ammonium nitrate (UAN) and ammonium nitrate (AN) are highly corrosive liquid fertilizer products. Corrosion of mild steel equipment used for processing, transporting, and storing UAN/AN solution can be extensive.

Treating UAN and AN corrosion with the right inhibitor can help nitrogen and syngas plants avoid unscheduled plant shutdowns, preserve assets such as storage tanks and rail cars, and meet environmental goals.

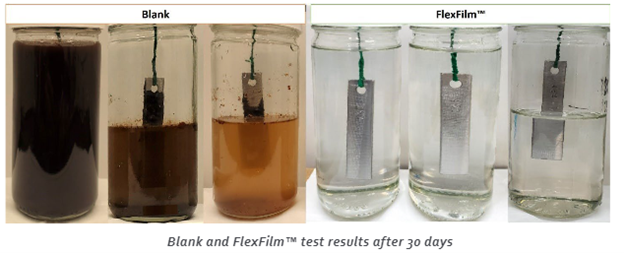

ChemTreat’s FlexFilm series of products provides excellent corrosion inhibition for mild steel under various operating conditions. These products are a synergistic combination of surface-active agents and organic acids for corrosion protection. As can be seen from the data below, FlexFilm products are shown to provide superior corrosion inhibition in the liquid phase and in the liquid/vapor interphase.

Results are examples only. They are not guaranteed. Actual results may vary.

Our industry experts support the environmental initiatives of our nitrogen and syngas industry customers.

Our industry experts support the environmental initiatives of our nitrogen and syngas industry customers.

Our ingenuity and applications expertise can assist in the following areas:

ChemTreat is committed to developing new technologies and services to help your facility meet its environmental goals.

This cloud-based software helps our customers make real-time, data-driven decisions to:

CTVista®+ combines the collective wisdom of experienced water treatment professionals with real-time data to optimize the effectiveness of the chemical treatment program at your facility.

Compatible with most industry-standard equipment setups, CTVista®+ is easy to integrate with your existing equipment. Our team can also work with you to create and install a custom equipment package best-suited to your facility’s needs.

Our experts at ChemTreat can help you develop a custom water treatment program for your facility. Our water treatment solutions and monitoring software helps plants like yours improve production efficiency, reduce operating costs, and easily integrate water treatment into your ESG initiatives.