-

USA - English

- Locations

- SDS Access

- CTVista®+ Login

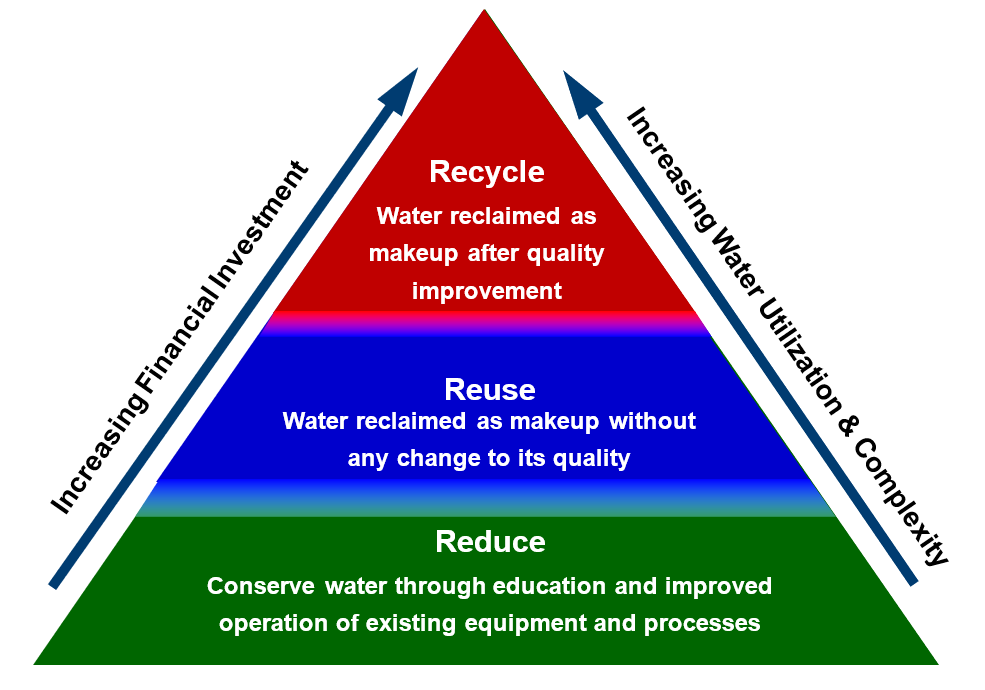

Heating, ventilation, and air conditioning (HVAC) systems consume vast amounts of water and energy. However, if your facility is looking for ways to minimize energy and water consumption, a variety of treatment and conservation methods are available to help you meet your goals through reduction, reuse, and recycling.

The primary consumers of water and energy in HVAC systems are boilers, closed loops, and cooling systems.

In general, boiler systems provide heat for HVAC and other processes, consuming quite a bit of energy and potentially large amounts of water.

Closed loop systems are filled with a set volume of water, and they do not consume much water unless experiencing a leak. However, they do consume energy by pumping water around a facility, generally for heating and cooling purposes.

Evaporative cooling towers consume a great deal of water and are one of the most efficient methods for ejecting heat from inside a building or facility to the atmosphere.

Air-cooled chillers require approximately 1.5 kilowatts per ton of cooling, whereas water-cooled chillers use approximately 0.85 kilowatts per ton. A ton of cooling is equivalent to 12,000 Btu’s.

Air-cooled chillers have a much lower daily capacity than water-cooled chillers because they require more surface area. Their capacity is typically limited to 7.5–500 tons of cooling, whereas water-cooled chillers can be quite large, with a capacity of up to 4,000 tons.

| Air-Cooled Chillers | Water-Cooled Chillers | |

| Efficiency | 1.5 kW/ton of cooling | 0.85 kW/ton of cooling |

| Capacity | 7.5–500 tons | 10–4,000 tons |

The purpose of an evaporative cooling tower is to maximize the surface area of the water flow to transfer heat to the atmosphere through evaporation of water. Air is pulled up through water falling through or spraying down through the cooling tower, and heat is drawn out. This process can waste a great deal of water if not optimized with proper treatment and control; therefore, cooling towers should be one of the first pieces of equipment you evaluate when looking to reduce water usage.

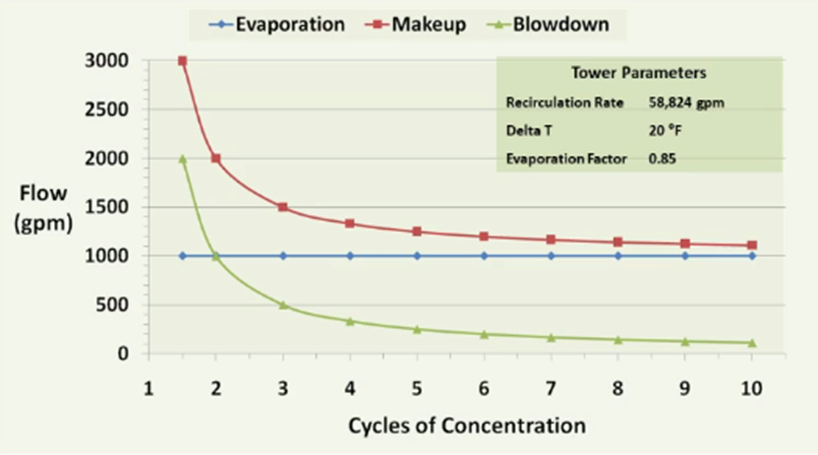

This graph depicts the relationship between the makeup water added to a cooling tower, discharged blowdown, evaporation, and cycles of concentration. The amount of evaporation depends on the amount of heat added to the cooling water by system processes. This heat is removed and ejected to the atmosphere outside. This is relatively constant as dictated by the heat expelled by the chiller to the water. Every pound of water evaporated through the tower removes nearly 1,000 Btu’s of heat.

The amount of makeup and blowdown water depends on the cycles of concentration, or how many times each volume of water is evaporated. In a once-through system, water passing through the tower is sent directly to the drain. These evaporative cooling towers consume the most amount of water. Without controlling blowdown, 1.25–1.50 cycles is the typical range. With some blowdown control, at 2 cycles of concentration, the makeup water requirement drops from 3,000 to 2,000 gpm, a reduction of over 30%. Savings further increase from 2 to 3 cycles with a 25% reduction; however, as the level approaches the constant volume of evaporated water (indicated by the blue line in the graph above), returns begin to diminish.

Increasing cycles can contribute to a higher mineral concentration as water evaporates, which can lead to scaling and fouling. These issues need to be controlled to maintain system efficiency.

At installation, new equipment runs at maximum efficiency. The goal of a good water treatment program is to maintain equipment in like-new, as-manufactured condition by keeping surfaces clean and mitigating corrosion and microbiological blooms. Fouling from dissolved minerals in makeup water can insulate heat transfer surfaces if not managed properly. Corrosion deposits on heat exchanger surfaces pose another risk, as does direct exchanger surface corrosion caused by heat flux. Corrosion products can insulate heat exchanger surfaces, impairing equipment performance while requiring greater energy to achieve the same degree of cooling.

Use of high-quality makeup water helps preserve equipment’s as-manufactured condition. Additionally, fouling potential must be balanced with the maximum degree of evaporation.

When seeking to improve sustainability, alternative sources of makeup water should be investigated to supplement and reduce the primary makeup source. A trained water treatment team can audit your water systems and come up with suggested sources of reuse water.

Chemical inhibitors are used to mitigate the interrelated processes of corrosion deposition and biofouling from bacteria and algae or plant life. Corrosion can lead to deposition, and corrosion and deposition can both lead to biofouling. These issues will negatively impact system efficiency.

If you’re looking to conserve energy at your facility, keep the following in mind:

| 500-Ton Chiller | Clean Condenser | Scaled Condenser |

| Electrical Costs | $80,000/year | $105,000/year |

| Water Use | 7,200,000 gallons/year | 7,200,000 gallons/year |

| CO2 Generation | 2,500,000 pounds/year | 3,310,000 pounds/year |

Recycling water entails treating streams of otherwise unsuitable water by investing in treatment and equipment to obtain high-quality water.

The first step in reducing water usage is to ensure systems are operating at maximum efficiency. Strategies may include:

Educating yourself on the operations and needs of your system is a vital step for effective water and energy reduction. This can consist of:

Depending on its quality, some of the water used in your facility may be reused in other processes without requiring a heavy investment in pretreatment equipment.

Examine the quality of any water you may want to add to makeup streams. If the quality of the water is sufficient for reusing in other processes, you can install equipment to capture that water and plumb it to a usable location.

For example, boiler blowdown may replace city water in closed loops, eliminating boiler additions to the discharge stream and reducing costs.

Cooling tower water is not reusable if a constituent in the water is at its maximum stable concentration, limiting additional cycling. A cooling tower operating efficiently will maximize the concentration of the minerals in the water. The resulting concentrated water can contribute to scaling when reused if not properly pretreated to remove dissolved solids.

Recycling saturated cooling tower water involves capturing effluent and installing equipment such as reverse osmosis (RO) systems or softeners to remove calcium and magnesium, the two primary components of scale formation caused by over-cycling.

Many plants underutilize gray water generated at their local municipal facilities. Gray water is different from water containing sewage; it typically comes from washing applications (showering, washing machines, etc.).

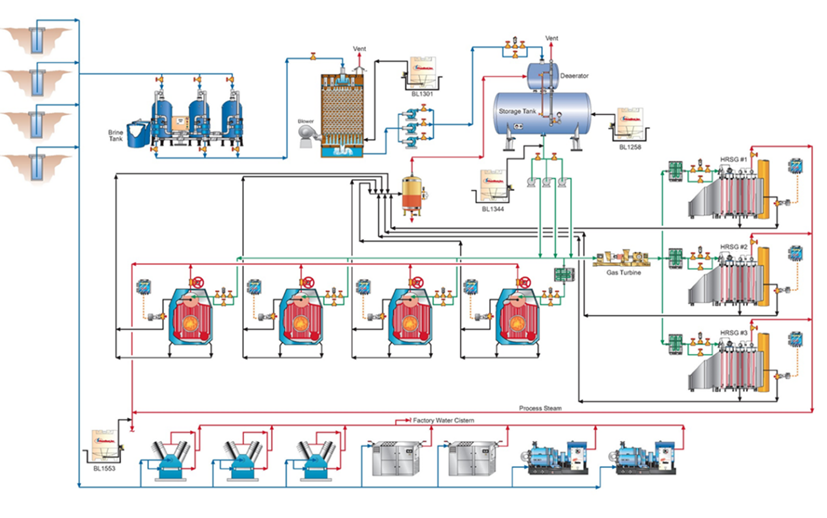

The ChemTreat team can evaluate your existing treatment program and historical system data to gain a deep understanding of how water is used at your facility. During their tour of your plant, our representatives can create a sketch of the water systems, which our Visual Design team can turn into a detailed schematic for your reference.

These illustrations are useful to help understand how water is balanced through a facility, where water is flowing, and where it is discharged.

Our representatives will note areas in your systems where energy and/or water are being wasted and work with our subject matter experts to put together a report outlining recommendations for system improvements.

Computer programs like ChemTreat’s CTVista®+ intelligent water management software provide additional insight to augment in-person audits. We use both in-house and third-party water modeling programs to come up with recommendations for optimizing water usage.

These programs can advise on key system parameters such as pH and saturation of minerals such as calcium, magnesium, and silica. The Langelier Saturation Index can be used to determine the optimum range for operation without wasting water. A good operating window includes avoiding:

Automation is recommended for optimizing cooling systems and helping prevent waste and fouling. Even small fouling levels are cumulative and can eventually impair efficiency, so correcting issues as soon as possible is recommended.

Automation offers superior on-line control and monitoring of water treatment chemistries. The data collected by automation technology also improves KPI monitoring to ensure results are being achieved and sustained.

Traditional methods for monitoring and controlling water systems involve grab samples and bench testing to analyze inert tracers present in chemical treatment. These traced chemicals can present increased treatment costs.

Newer methods use ion-selective electrodes to directly read inhibitor levels, eliminating the need for sampling and water conditioning. These low-maintenance sensors can output information to data logging software. Specific parameters such as water flow, temperature, pH etc. can be tracked to alert operators when water quality is outside the specified limits.

Software such as CTVista+ can also compile collected data to generate reports that can be sent to operators on a regular basis to increase visibility of system trends and offer insight into where adjustments may be needed.

Modeling software such as ChemTreat’s Condenser Performance Monitoring Program can gather plant data and analyze it to aid in pinpointing specific system issues as well as provide troubleshooting guidance. These tools can also help determine when a system cleaning is needed to maintain efficiency.

In a holistic water treatment program, all connected systems in a facility or campus are evaluated to ensure downstream performance is not negatively impacted by upstream treatment. Chemicals such as phosphates, for instance, should not be added if downstream systems are having bacteria issues.

Additionally, some inhibitors are limited by the EPA, making it difficult to apply enough product to achieve the desired results/protection.

It is not unusual for a cooling system program to contain phosphate, potassium, or nitrogen, which act as macronutrients and make it difficult to mitigate algae and bacterial blooms. This is a big reason the EPA limits these items in discharge.

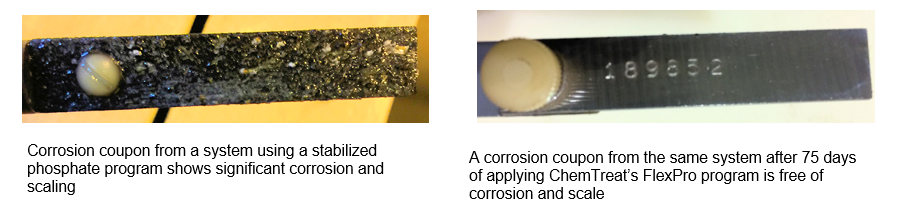

Applying cost-optimized inhibitors can increase sustainability gains. For instance, ChemTreat’s unique FlexPro® inhibitor offers a non-fouling treatment option.

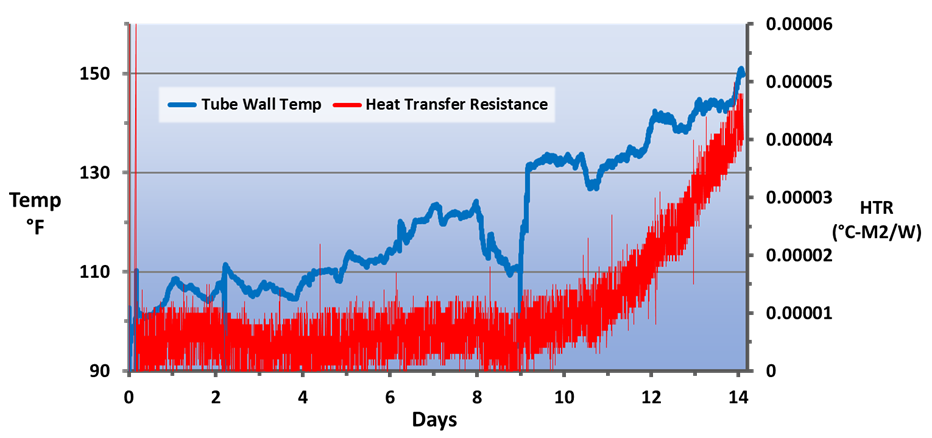

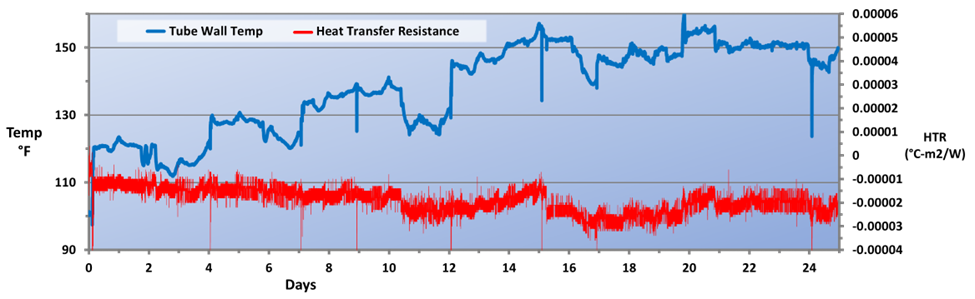

Phosphate reacts with calcium to form calcium phosphate scale on heat exchanger surfaces. The following charts illustrate the relationship between water or tube wall temperature and heat transfer resistance. This example is at a Gulf Coast site using phosphate treatment during a very hot summer. The high temperature increased saturation and caused phosphate fouling, which impaired performance. The operators performed periodic acid cleanings throughout the summer to restore heat transfer and remove calcium phosphate scale.

ChemTreat removed phosphate from the program to achieve excellent corrosion protection without fouling the heat exchangers. Heat transfer was maintained even on hot summer days, allowing the facility to stay on-line longer while reducing the frequency of acid cleanings. This improved the site’s environmental outlook, as acid cleanings can expel contaminants to wastewater plants and the environment while also elevating greenhouse gas emissions by increasing the quantity of solids and phosphates in the discharge water.

Results are examples only. They are not guaranteed. Actual results may vary.

To enhance the sustainability of your water systems and treatment programs, it is important to keep the following steps in mind:

Work with your water treatment provider to find ways to reuse water at your facility. Water sources such as air handler condensate and rainwater tend to contain few contaminants and will not require much pretreatment for reuse.

Even seawater or water with high levels of dissolved solids can be recycled in plant processes if the proper equipment is in place. Investing in filtration and/or RO systems can help your facility recycle more water.

Request Sustainability Assessment

As with all other technologies, due diligence is necessary to determine the feasibility for utilizing these methods. It is always important to consult your equipment manuals and guides and seek guidance from your local water treatment representative to address your specific needs.

Technical Service Consultant

Richard H. Tribble is a graduate of Virginia Commonwealth University and has worked in water treatment since 1996. He has developed a multitude of high-performance cooling product formulations, has 6 patents under his name, and has authored numerous papers. He currently works as the Closed Loop Product Champion for ChemTreat as well as specializing in root cause failure analysis.