-

USA - English

- Locations

- SDS Access

- CTVista®+ Login

A major university medical complex needed to replace more than a dozen aging cooling towers and add ten new buildings, all while transitioning to a centrally located chiller plant.

As part of this new system, the facility wanted makeup water to come from five sources, each with varying water quality properties:

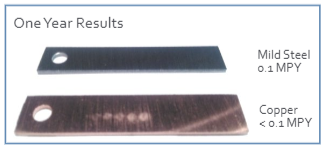

Facility personnel were also looking to save on costs and improve the sustainability of their water treatment program by extending the life of RO membranes and pre-filter cartridges, improving system monitoring, and reducing scale and corrosion.

The previous process was not capable of handling a new 32,000-ton centralized plant using multiple makeup water sources.

The university partnered with ChemTreat for in-depth expertise and on-site support with this project.

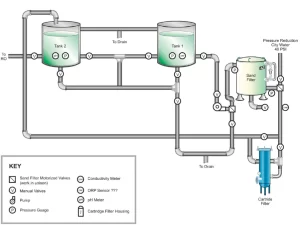

After a thorough system evaluation, the ChemTreat team provided a list of recommendations and worked with the university to implement the improvements.

ChemTreat's recommendations included:

Thanks to the installation of CTVista, all team members with data access could write reports and other observations within a centralized system, allowing all program participants to review data and determine the appropriate course of action.

With ChemTreat’s support, the university was able to save over $500,000 per year in water costs thanks to improvements to its water treatment processes.

Annual water savings from reclamation projects:

Results are examples only. They are not guaranteed. Actual results may vary.