-

USA - English

- Locations

- SDS Access

- CTVista®+ Login

An automotive assembly plant in the Midwest was having performance issues in their paint sludge system, leading to quality problems and an increase in overall costs.

Paint solids were building up in the underbooth and pit, increasing maintenance requirements. Odors in the plant production areas also became an issue, and paint solids were exiting the stacks and landing on vehicles in the parking lot.

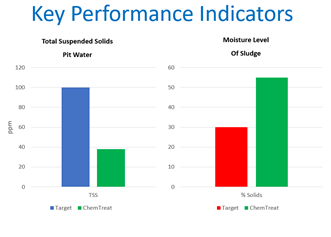

High suspended solid concentrations caused excessive foam and poor solids removal. The percent solids level of the sludge removed was less than 30%, resulting in higher hauling costs.

ChemTreat performed a complete system audit and developed a custom water treatment solution.

Optimized Chemistry

Improved Chemical Feed

Improved Service Program

Through the ChemTreat program, the customer experienced the following results and savings:

Results are examples only. They are not guaranteed. Actual results may vary.