Our Commitment to Environmental, Social, and Corporate Governance (ESG)

Water scarcity is here today, increasing the urgency for bold leadership. We view sustainability as a fundamental responsibility and an important strategic priority that touches every aspect of our business.

Having an ESG strategy is critical for our customers as they invest for future growth. ChemTreat recognizes the important role of advanced water and process treatment solutions in meeting sustainability goals. We focus our innovation efforts on new technologies anticipating future challenges our customers will face as they reach their sustainability goals. Together we can continue protecting the world’s precious resources.

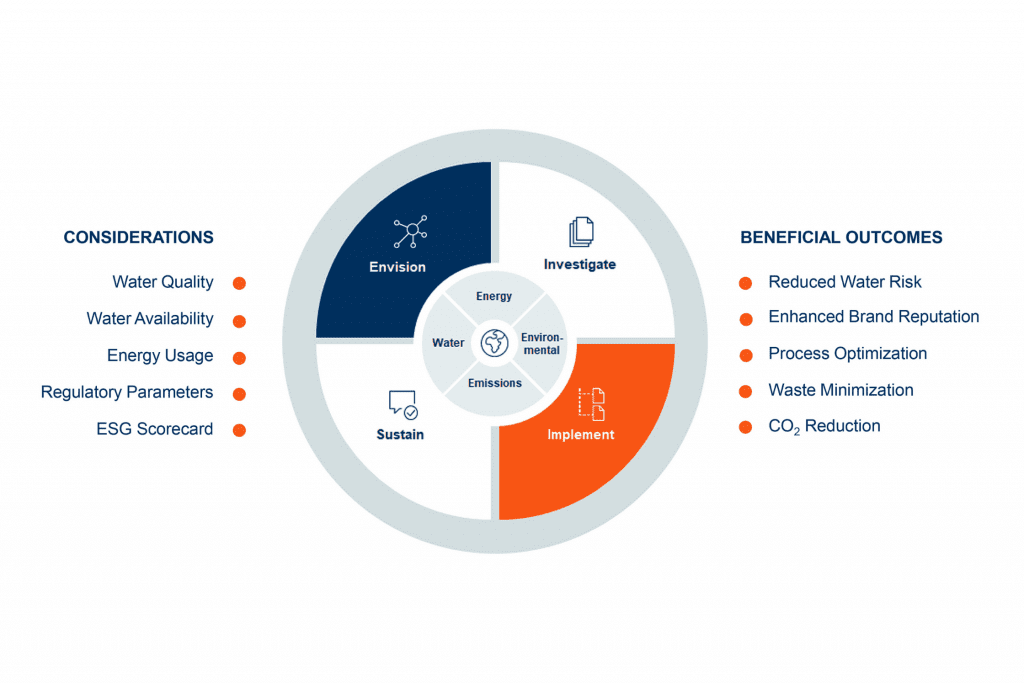

Putting ESG Principles into Action

Our experts work closely with our customers to quantify water-related risks, set targets, take action, and track performance, helping them meet their environmental impact goals. We offer advanced water treatment options, programs to reduce water, chemical, and energy usage, and monitoring and reporting tools to track sustainability metrics and measure water reuse initiatives.Alignment with the 17 United Nations Sustainable Development Goals

In 2015, all United Nations Member States agreed to implement the 2030 Agenda for Sustainable Development, the core of which are the 17 Sustainable Development Goals.

ChemTreat offers programs and services that align with many of the UN standards. Our industry experts can support ESG initiatives to help our customers meet and exceed the following goals:

Goal 6: Ensure availability and sustainable management of water and sanitation for all. (Read more.)

Goal 6: Ensure availability and sustainable management of water and sanitation for all. (Read more.)

Our ingenuity and applications expertise can assist with:

- Increasing cycles of concentration to minimize blowdown in cooling towers and boilers

- Improving heat transfer across heat exchangers to reduce fan energy and cooling water usage

- Applying reverse osmosis antiscalants to increase recovery rates, reduce concentrate flows and energy, and extend asset life

- Implementing smart controllers and solid chemical feed for water treatment

- Providing consultation and treatment programs for water reuse projects

- Measuring and reducing corrosion rates to improve performance and extend asset life

- Helping facilities achieve zero-liquid discharge

- Running cooling towers at higher pH to reduce acid usage and CO2 emissions

- Documenting water and energy savings, as well as carbon emissions reductions

These innovations will help our customers improve water quality by reducing hazardous chemical discharge, increasing water use efficiency, implementing integrated water resources, and protecting water-related ecosystems.

Goal 9: Build resilient infrastructure, promote inclusive and sustainable industrialization and foster innovation. (Read more.)

Goal 9: Build resilient infrastructure, promote inclusive and sustainable industrialization and foster innovation. (Read more.)

Innovation defines our future. Our R&D team is continually developing new chemistries and improving existing solutions to help customers meet increasingly ambitious environmental goals. Our recent innovations include:

- Phosphate-free and zinc-free cooling corrosion and scale inhibitors

- Non-metal and non-PBT (Persistent Bioaccumulative Toxic Substances) chemistries

- Advanced formulations to reduce water usage and handle challenging issues such as high LSI and silica concentrations

- Solid chemistries to help decrease carbon footprint and reduce exposure

- Natural coagulants to replace oil-based products for wastewater treatment

- Products for toxic chemical and heavy metals removal

- Products for removing TOC/BOD in effluent

Our continued focus on developing cutting-edge sustainable solutions provides extensive opportunities for our customers to increase resource-use efficiency and implement environmentally sound processes.

Goal 12: Ensure sustainable consumption and production patterns. (Read more.)

Goal 12: Ensure sustainable consumption and production patterns. (Read more.)

ChemTreat is working to reduce CO2 emissions and water usage in our manufacturing process and supply chain to foster eco-friendly production. We also help our customers reduce water and energy usage at their facilities with our chemical treatment offerings, water reuse projects, and automation and control capabilities.

We are committed to reducing waste generation and promoting the sustainable management of our products throughout their life cycle.

Goal 13: Take urgent action to combat climate change and its impacts. (Read more.)

Goal 13: Take urgent action to combat climate change and its impacts. (Read more.)

ChemTreat’s R&D team has developed innovative technologies to help our customers meet their goals designed to combat climate change. Examples include:

- ECR® electrode consumption reduction technology, which has helped EAF and LMF steel mills eliminate an average of 500–1,200 tons of CO2 annually per furnace

- SeQuester® technology, which helps mining, power, refining, and chemical facilities remove selenium, a priority pollutant, from their process and wastewater streams, enabling them to meet discharge regulations

Goal 14: Conserve and sustainably use the oceans, seas, and marine resources for sustainable development. (Read more.)

Goal 14: Conserve and sustainably use the oceans, seas, and marine resources for sustainable development. (Read more.)

Phosphate discharge into waterways has caused an increase in toxic algae blooms, which results in the destruction of aquatic life. Because of the significant impact of phosphorus on water resources, many countries now regulate phosphorus as an aquatic nutrient. According to the USEPA, nutrient pollution from phosphorus and nitrogen is “one of America’s most widespread costly and challenging environmental problems” (USEPA 2017a).

To help combat this phenomenon, ChemTreat has developed FlexPro®, a suite of cooling system treatment products, many of which effectively inhibit corrosion and scaling without the use of phosphates. Many FlexPro products also do not contain zinc, another chemical that is becoming increasingly more regulated as its presence in the environment can cause harm. Reducing phosphorus and zinc in effluent waste from cooling tower blowdown helps our customers preserve marine life.

These efforts align with the UN’s efforts to reduce marine pollution and improve sustainable management of marine and coastal ecosystems.

Goal 15: Protect, restore, and promote sustainable use of terrestrial ecosystems, sustainably manage forests, combat desertification, and halt and reverse land degradation and halt biodiversity loss. (Read more.)

Goal 15: Protect, restore, and promote sustainable use of terrestrial ecosystems, sustainably manage forests, combat desertification, and halt and reverse land degradation and halt biodiversity loss. (Read more.)

ChemTreat’s programs helps our customers reduce solid/effluent waste as well as air contaminants from cooling towers. We work closely with our customers to help them conserve their local ecosystems while simultaneously improving the efficiency of their operations.

EcoVadis Sustainability Rating

Since 2007, EcoVadis has helped companies assess performance and sustainability practices and develop benchmarking for future growth.

ChemTreat currently holds a Silver Sustainability Rating from EcoVadis. We are committed to improving this rating so we can continue to support our customers’ environmental goals.

LEED Credit Assistance

The Leadership in Energy and Environmental Design (LEED) Green Building Rating System is the worldwide standard for the design, construction, and operation of green buildings. The LEED rating system is designed to help maximize operational efficiency while minimizing environmental impact.

ChemTreat supports customers gaining LEED points in the following areas:

Water Management

Comprehensive water management programs to help you maintain reliable heat transfer systems and improve water usage efficiency. Our programs not only help you significantly reduce energy consumption but also improve the quality of indoor environments.

Operational Innovation

Significantly reduce the resource requirements and carbon footprint of your water treatment program. Our programs are designed to extend asset life and optimize dosing and control of water treatment applications.

Intelligent Water Management

Our CTVista®+ cloud-based, intelligent water management platform enables monitoring and control of your water treatment programs by providing:

- Data management

- Analytics

- Reporting

- Real-time guidance

CTVista®+ helps you make real-time, data-driven decisions. It’s a dynamic way to manage and optimize critical water treatment operations and help you track and report on your sustainability metrics.

We take our customers’ data security and integrity very seriously. CTVista®+ uses extensive safeguards and industry best practices to protect your data.

Customer Education Programs

- Team training to assist customers with water management program startup

- Seminars and workshops to communicate best practices and new technologies

- Audit programs to enhance operational efficiency and highlight cost savings opportunities

Our Commitment to Environmental Impact

To drive accountability and continuous improvement, Veralto™ has established goals designed to achieve meaningful improvement to our Environmental, Health, and Safety (EHS) performance and reduce our impact on the environment.Click here to view the Veralto Sustainability Report.

EHS Information Management System

We use a third-party, global EHS information management system to collect and manage EHS information, including:

- EHS incident, severity, investigation, and corrective action tracking

- EHS performance metric reporting and tracking

- Sustainability-related metric reporting and tracking

- A compliance calendar for managing compliance and other recurring tasks

- Tracking incident remediation, audit, and inspection findings

Certifications

ChemTreat has emphasized the consistent quality of our products since the company was founded, and these principles were formalized into a written quality program in 1988. This system supports our corporate mission of developing partnerships with our customers through providing outstanding customer service, high-quality products, and superior technical expertise. Our commitment to quality is based on total employee involvement in continuous improvement of the entire organization.

Building on this foundation, ChemTreat achieved recognition for the effectiveness of our quality system in 1994 by attaining ISO 9000-series certification at our manufacturing facilities located in Ashland, Virginia; Nederland, Texas; and Eldridge, Iowa; and for the corporate functions supporting our operations. We are certified to the current ISO 9001:2021 standard for Quality Management and the current ISO 14001:2021 standard for Environmental Management.

Learn more about ChemTreat’s Environment, Health, and Safety policy here.

Our Commitment to Diversity and Inclusion

We know diverse and inclusive teams create real breakthroughs because they allow room for big ideas, encourage all voices to be heard equally, and facilitate diverse perspectives. We seek to continuously improve and sustain a diverse and inclusive culture free of systemic bias and create a work environment in which all associates feel they belong.Our Corporate Governance Standards

As a Veralto operating company, we are committed to maintaining the highest ethical standards and complying with all applicable laws wherever we do business.

Every Veralto associate is personally accountable for following our ethics and compliance policies. Veralto empowers all associates by providing training on a variety of ethics and compliance topics, helping associates understand their obligations under the law, the expectation to act ethically, and how to manage the risks inherent in their job function.

In 2020, the Annual Training Program included the following courses (specific courses assigned to a particular associate are based on the associate’s role and level within the organization):

- Code of Conduct

- Creating a Harassment-Free Workplace

- Cyber Security

- Data Privacy and Protection

- Environment, Health, and Safety

- Global Anti-Bribery and Anti-Corruption

- Insider Trading

- Marketing and Advertising of Medical Devices

- Quality Systems Regulations: Good Manufacturing Processes