Introduction to Corrosion, Scale, and Biofouling Control in Cooling Systems

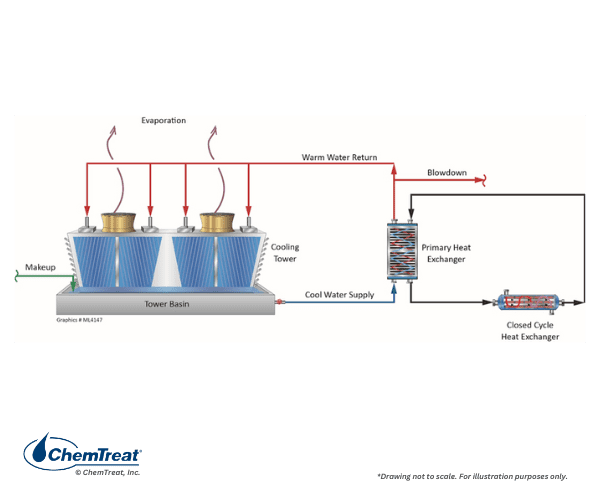

The previous chapter outlined fundamentals of cooling tower and heat exchanger design/operation. In this chapter, we examine cooling water chemistry and treatment programs to maintain reliability throughout the cooling water network.

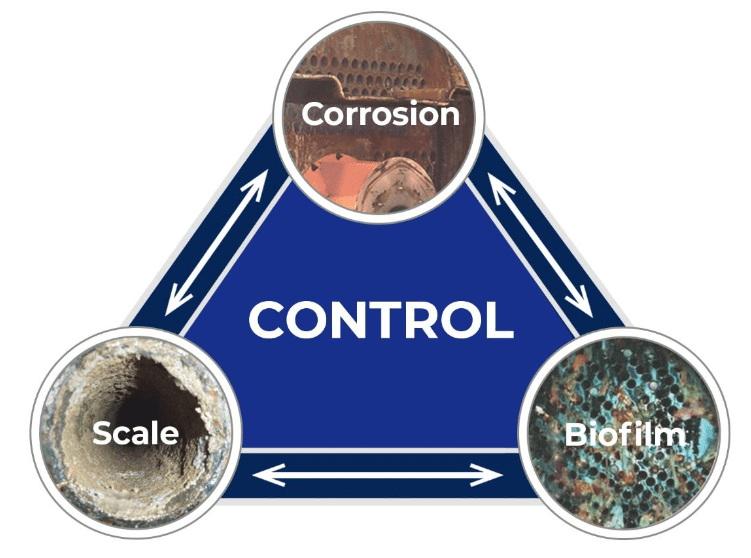

Cooling systems require protection from corrosion, scaling, and biofouling (or microbiological fouling) to maximize performance. A symbolic representation of these issues and their interdependence is shown below.

Corrosion, scale, and biofouling control must be considered in a holistic manner. A fourth, increasingly important factor is the potential environmental impact of water treatment chemistry, especially regarding chemicals that could appear in the plant discharge. Treatment programs that were once commonplace may no longer be allowed or may be severely restricted due to discharge regulations.

While treatment methods often have several functions, a key aspect is protection of metal surfaces. In the next sections, we review the most common corrosion mechanisms and control methods.

Table of Contents

A Brief Review of Cooling System Metallurgy and Materials Makeup

Primary Metal Corrosion Mechanisms

Types of Corrosion

Deposition Mechanisms

Scale Formation

Deposition and Corrosion Control

Corrosion Control

Filming Chemistry

Closed Cooling Water (CCW) Corrosion Control

Corrosion Control via Materials Selection and Electrochemistry

Microbiological Concerns

Microbiological Control

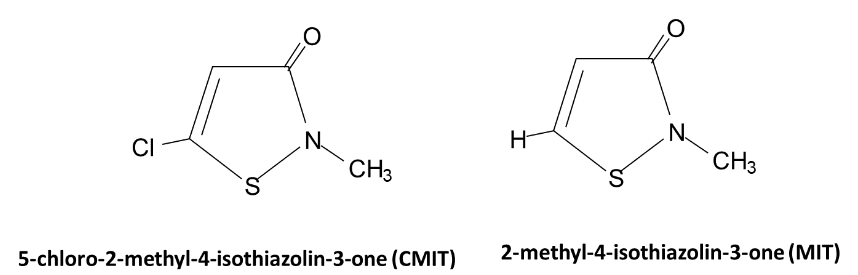

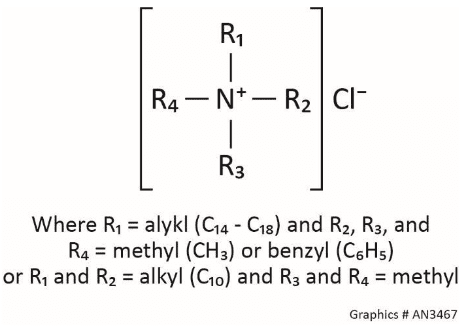

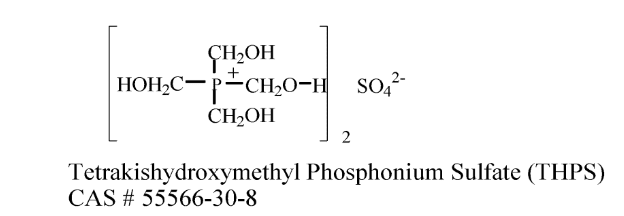

Oxidizing and Non-Oxidizing Biocides

Cleaning and Sanitization of Microbiological Foulants

Macrofouling Control Methods

Microbiological Monitoring Methods

Monitoring of Oxidizing Biocides

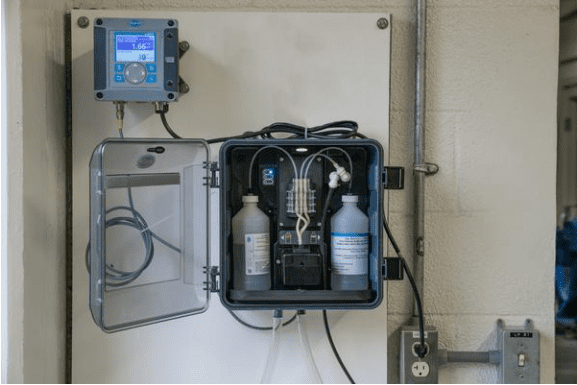

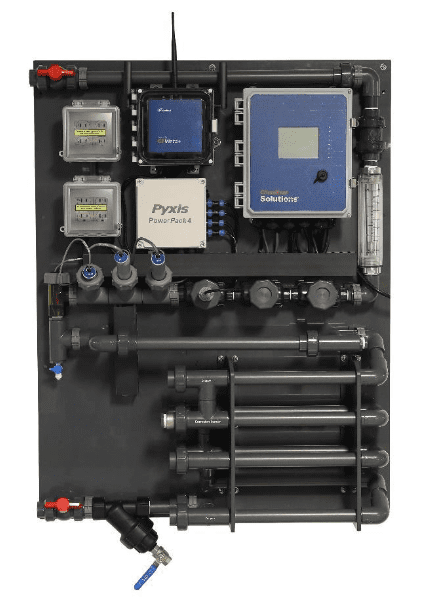

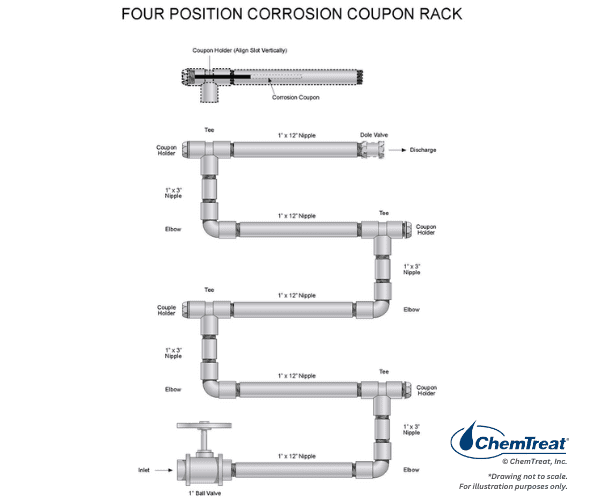

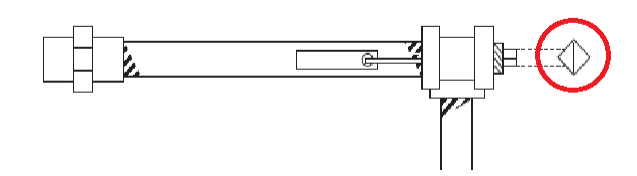

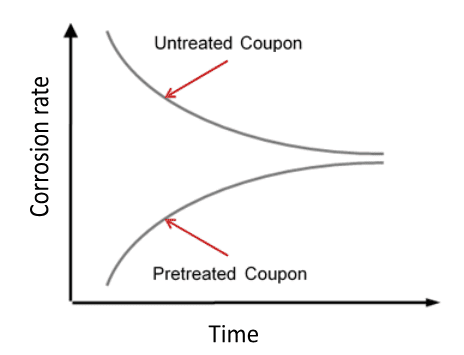

Chemical Feed, Deposition, and Corrosion Monitoring

Cooling System Cleaning and Passivation

Conclusion

A Brief Review of Cooling System Metallurgy and Materials Makeup

As a quick review, the typical material for cooling system piping and many heat exchanger (HX) shells is mild carbon steel. HX tubes or plates may be of stainless steel, copper alloys, titanium, aluminum, or in some cases, expensive corrosion-resistant alloys. Galvanized steel fasteners are often present in cooling towers, while smaller towers may be predominantly galvanized. Most large cooling towers have concrete basins, and some still have wooden structural components. Thus, the complete cooling system may comprise a variety of materials, where knowledge of all is essential for the selection of reliable corrosion control programs.

Primary Metal Corrosion Mechanisms

Metal corrosion is an electrochemical process in which metals in a refined state revert to their natural form. Iron is the classic example. According to reference 1 “Earth’s most important iron ore deposits are found in sedimentary rocks. They formed from chemical reactions that combined iron and oxygen in marine and fresh waters. The two most important minerals in these deposits are the iron oxides hematite (Fe2O3) and magnetite (Fe3O4). These metal ores have been mined to produce almost every iron and steel object that we use today.” Iron-based materials and other metals when placed into service can be attacked in a variety of ways. The most observable is the reaction of iron or mild steel with water and oxygen to produce rust, but other corrosion mechanisms are common. The most prevalent include:

- General or uniform corrosion

- Pitting

- Crevice corrosion

- Erosion corrosion

- Microbiologically influenced corrosion

- Stress corrosion cracking, corrosion fatigue, and intergranular corrosion

- Galvanic corrosion

- Selective leaching or dealloying

Proper corrosion control is necessary to prolong equipment life; minimize transport of corrosion products to other locations; and at times to ensure employee safety.

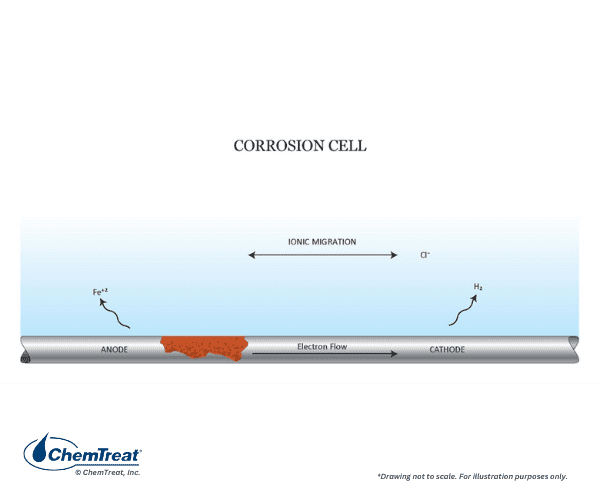

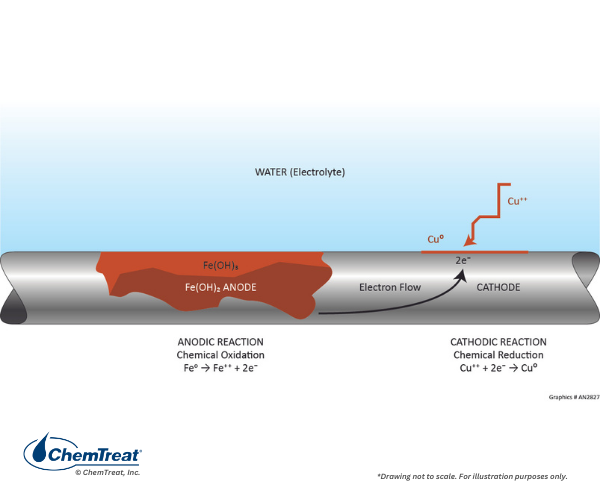

Corrosion Cell

The driving force for corrosive reactions is the electrical potential between the electron acceptor (the corrosive medium) and the electron donor (the metal). The following example illustrates the fundamental corrosion process. It is the simple laboratory experiment of immersing an iron bar in a hydrochloric acid (HCl) solution. Almost immediately, bubbles will appear all along the submerged surface of the bar, and within a relatively short time, corrosion will become plainly visible. Figure 7.2 summarizes the chemistry.

Three reactions explain the overall process:

- Each iron atom at a corrosion site gives up two electrons (oxidizes), and thus transforms from a zero oxidation state to a +2 oxidation state, Fe0 → Fe2+ + 2e– (Eq. 7-1). The Fe2+ (ferrous) ions migrate into the solution. These sites are known as anodes.

- Electrons released at the anodes flow through the metal to other sites where they react with the hydrogen ions (reduction) of the acid to produce hydrogen gas, 2H+ + 2e– → H2↑ (Eq. 7-2). Reduction occurs at the cathodes.

- Chloride ions (Cl–) and ferrous ions migrate through solution to produce solvated ferrous chloride (FeCl2) and complete the electrical circuit.

In this particular case, anodes and cathodes form all along the metal surface. Many hydrogen bubbles immediately form, and shortly thereafter visible corrosion appears on the entire bar. This is an example of general corrosion, where anodes and cathodes shift constantly, and it is also a classic example of an oxidation-reduction or “redox” reaction.

Every metal exhibits a different tendency to release or accept electrons, and as will shortly be shown, the corrosive agent has a large influence. The list of half-cell metal potentials as compared to the hydrogen half-cell potential is useful and instructive.

2H+ + 2e– ⇌ H2↑ E0 = 0.00 V for a 1 molar solution by definition

The following table highlights the potentials of several of the most common metals.

Table 7-1. Half-Cell Potentials for Well-Known Metals as Compared to the Hydrogen Half Cell

| Electrode Reaction | Standard Electrode Potential (V0) |

| Mg → Mg2+ + 2e– | 2.363 |

| Al → Al3+ + 3e– | 1.662 |

| Zn → Zn2+ + 2e– | 0.763 |

| Fe → Fe2+ + 2e– | 0.440 |

| H2 → 2H+ + 2e– | 0.000 |

| Cu → Cu2+ + 2e– | -0.340 |

| Ag → Ag+ + e– | -0.800 |

| Au → Au3+ + 3e– | -1.420 |

From this table, we can derive several important concepts.

- The metals above hydrogen in the table will all corrode in acid.

- Consider again the reaction shown in Figure 7.2. The table indicates that iron has a significant reaction potential when compared to acid.

- Copper (and typically its alloys) are on the “noble” side of the hydrogen half-cell potential, meaning that it remains stable in common mineral acids. Oxidizing agents are typically needed for corrosion.

- Silver and gold are two of the truly noble metals. Especially for gold, special solutions, e.g., aqua regia, are needed to dissolve the metal.

- This data is also important for determining the probability of galvanic corrosion when two dissimilar metals are coupled in a water environment. Galvanic corrosion is examined in more detail later.

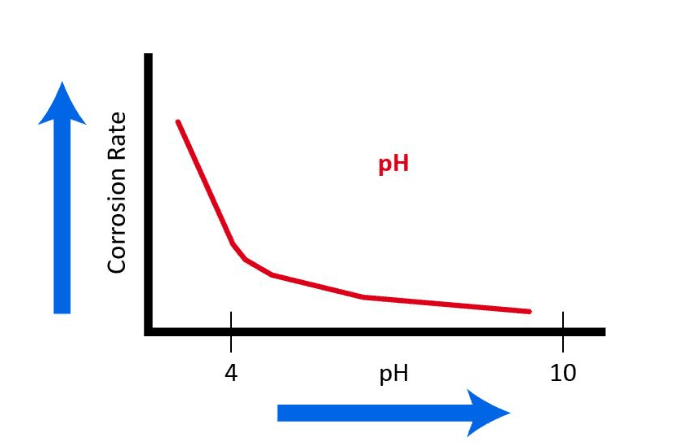

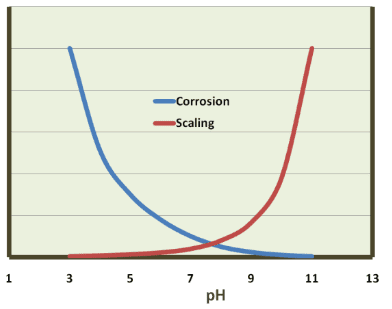

With regard to the common structural material of many cooling water systems, mild streel, Figure 7.3 illustrates the influence of pH, i.e., the hydrogen ion concentration.

Accordingly, most modern cooling system chemistry programs operate within an upper-7 to mid-8 pH range. In these conditions, a thin, passive CaCO3 layer may form to further inhibit corrosion. However, as was briefly discussed in Chapter 6 and will be re-examined later in this chapter, calcium carbonate scale formation can be one of the most troublesome problems in cooling systems.

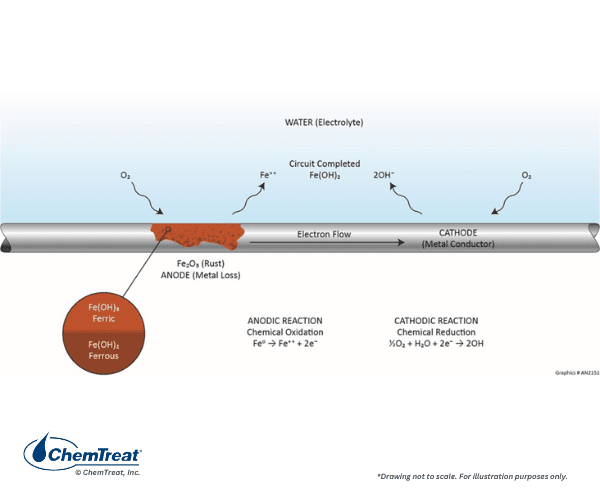

If acid was the only corrodent in a cooling water system, corrosion control would be straightforward. Unfortunately, numerous other cathodic reactions are possible, with the most prevalent being oxygen reduction in neutral or alkaline solutions.

The anodic reaction is the same as previously shown.

- Fe0 → Fe2+ + 2e‒ | Eq. 7-1

Oxygen is reduced at the cathode:

- ½O2 + H2O + 2e‒ → 2OH‒ | Eq. 7-3

The hydroxide ions combine with Fe2+ to form ferrous hydroxide:

- Fe2+ + 2OH‒ → Fe(OH)2 | Eq. 7-4

In the oxygen-laden environment, additional reactions occur. First, ferrous hydroxide will continue reacting with oxygen to form ferric hydroxide:

- 2Fe(OH)2 + ½O2 + H2O → 2Fe(OH)3↓ | Eq. 7-5

The reactants shown in Equations 7-4 and 7-5 are in equilibrium with other iron oxide species, as shown below:

- Fe(OH)2 ⇌ FeO + H2O | Eq. 7-6

- Fe(OH)3 ⇌ FeO(OH) + H2O | Eq. 7-7

Eventually, these products dehydrate to rust, which is brown-colored and offers no protection to the underlying metal:

- 2FeO(OH) ⇌ Fe2O3↓ + H2O | Eq. 7-8

Two other important aspects to consider are that in the electrochemical process, cathodic reactions dictate the rate of corrosion, while anodic reactions dictate the type of corrosion. As will be further outlined, situations can arise with a small number of fixed anodes in a large cathodic environment. This combination can lead to severe localized corrosion and potentially rapid failures.

The reader will observe that magnesium and aluminum are at the top of Table 7.1, and ask why these materials are used for many infrastructure purposes such as some airplane parts, electrical components, beverage cans, and so forth. The elements are so reactive that during the production process, a tight oxide layer forms on the metal surface and protects the base metal from further corrosion. Only acids or strong alkalis will attack this protective layer, so during normal service the metals remain quite stable.

Several other important factors influence most corrosion mechanisms. These are outlined below.

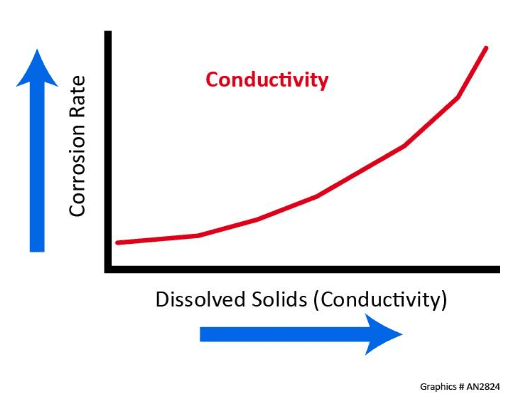

Conductivity

Corrosion is an electrochemical process, and, as the dissolved solids concentration increases, so does the corresponding conductivity and corrosion rate.

Consider cooling water in an open recirculating system that has a conductivity of 2,750 µS/cm, and compare that value to pure water with a theoretical conductivity of 0.055 µS/cm. The cooling water is 50,000 times more conductive than pure water.

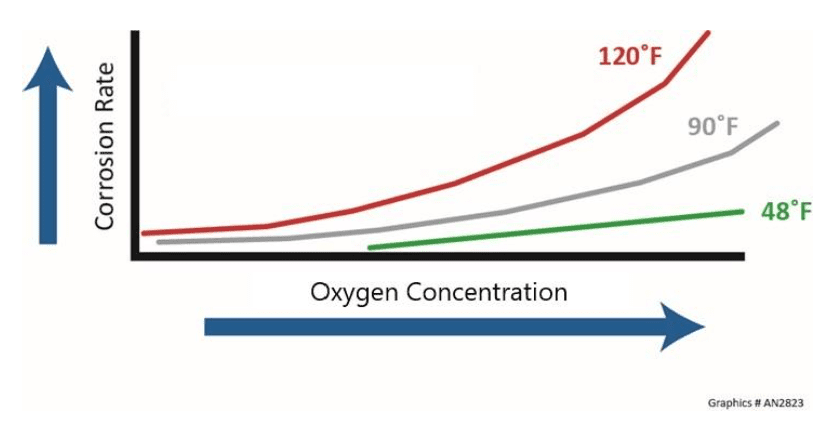

Temperature and Dissolved Oxygen Concentration

Temperature usually has a significant impact on corrosion rate, and a general rule of thumb suggests that the rate doubles with each 18°F (10°C) increase in fluid temperature. Additionally, the corrosion rate will, in general, double with every 10–20°F increase in metal skin temperature. Some processes may produce so much heat that molecular oxygen gas can form beneath deposits, exponentially influencing the corrosion process. The effect of temperature and oxygen concentration on corrosion rates is shown below.

Consider cooling water in an open recirculating system that has a conductivity of 2,750 µS/cm, and compare that value to pure water with a theoretical conductivity of 0.055 µS/cm. The cooling water is 50,000 times more conductive than pure water.

Water Velocity

Both high and low fluid velocity can be problematic regarding corrosion. High velocities may sweep away corrosion products (which sometimes protect the underlying metal), promoting further corrosion. Excessive velocities may also induce erosion-corrosion, as will be described later in this section. On the other hand, low flow or stagnant conditions can potentially enhance corrosion, as this may keep corrosive ions in long-term contact with the metal. A common guideline for linear flow rate through piping and heat exchanger tubes is 5–10 feet per second (fps), which provides a balance between corrosion/deposition control and material costs. However, every project requires careful analysis to optimize piping and equipment design and flow rates. For example, if for some reason a soft metal is needed for an application, a lower flow rate may be necessary to minimize erosion.

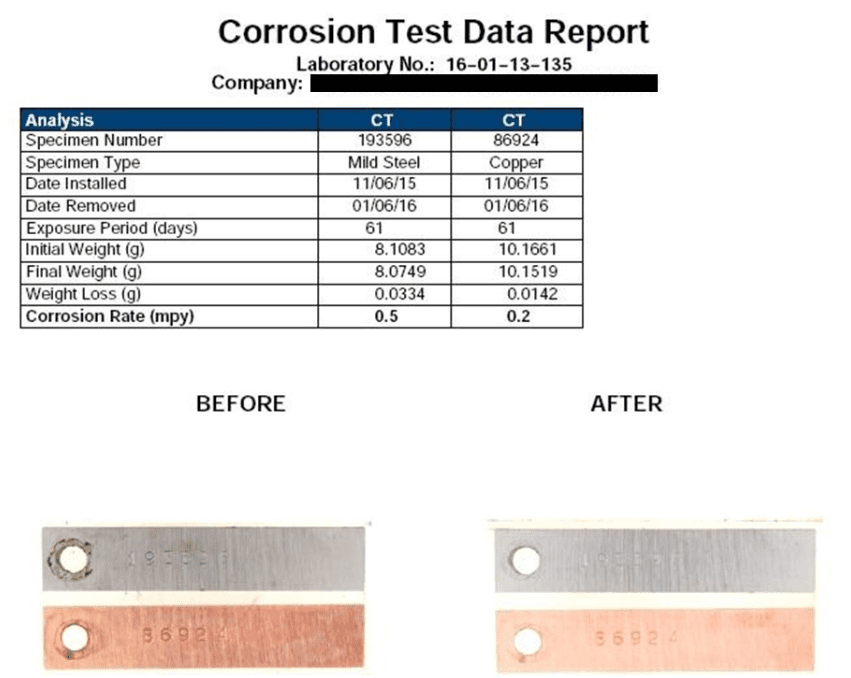

REFINERY IMPROVES CORROSION CONTROL & REDUCES OPERATIONAL COSTS WITH FLEXCORR™

Types of Corrosion

We will now examine the most common types of corrosion in cooling systems. Some, such as general corrosion, often allow long material life and can be controlled with straightforward treatments. Others, like pitting, have been known to cause through-wall penetrations of pipes and other equipment within months, and sometimes even weeks. Expensive unit shutdowns and material replacement may be the result.

General Corrosion

With general corrosion, the anodes and cathodes on the metal shift constantly, and localized corrosion sites do not develop. Metal life can be quite long when general corrosion is the only issue. The figures below illustrate two examples of general corrosion.

Materials selection and dimensions such as pipe wall thickness are often based on a 30-year life expectancy per general corrosion calculations. For example, consider a 6” diameter, Schedule 40 pipe with a wall thickness of 0.28 inches. When approximately 50 percent of the pipe wall has corroded, the pipe may be nearing failure and should be repaired or replaced. The common unit for corrosion rate is mils per year (MPY), where one mil is one-thousandth of an inch. In this example, a general, and not unreasonable, corrosion rate of 4.67 MPY would result in 50 percent wall loss after 30 years. Good corrosion control programs will minimize general corrosion, but as the next sub-sections outline, localized corrosion can be very destructive, and can be influenced by a variety of factors.

Pitting Corrosion

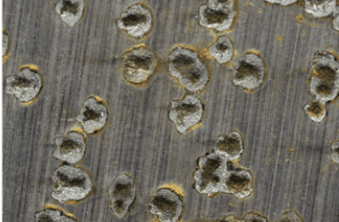

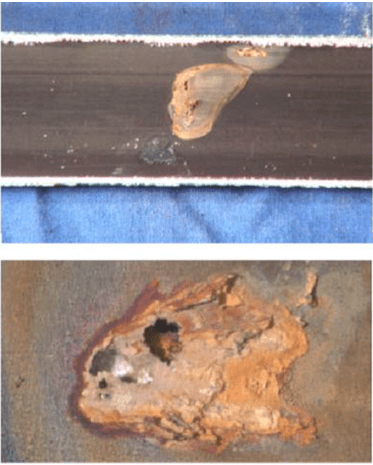

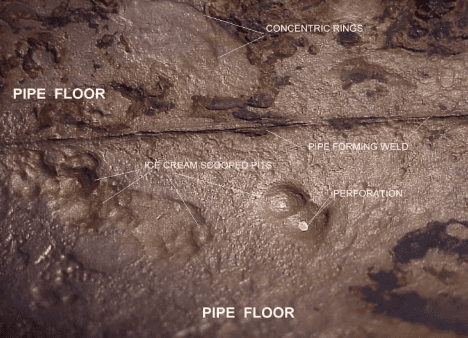

If corrosion becomes localized, permanent anodes will develop in a large cathodic environment. Pitting, or similar mechanisms as we shall observe, is the result, as shown below.

The corrosion rate may be the same as general corrosion, but damage is much more serious due to rapid penetration of the metal at anodes. Numerous mechanisms or conditions can initiate pitting. Solids deposits on steel may produce oxygen-depleted areas. These spots are anodic to clean steel. Microbiological colonies can do the same, and can also release corrosive compounds via metabolic processes. We will explore this phenomenon a bit later. Poor welding techniques can alter the chemical makeup of the metal at the weld location and increase corrosion susceptibility.

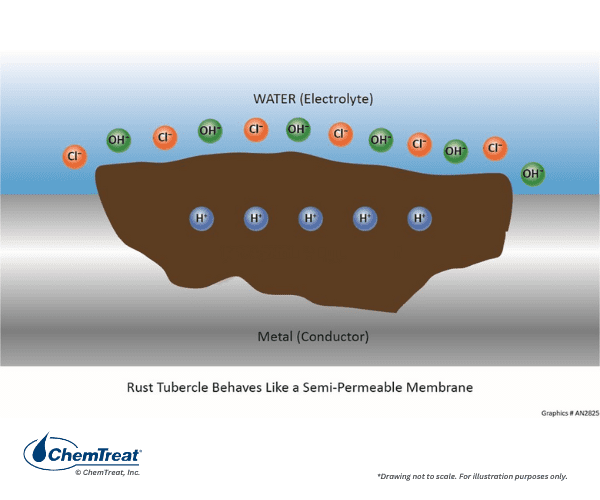

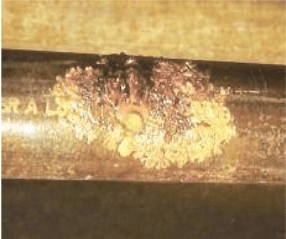

A phenomenon common with carbon steel is corrosion product (rust) accumulation over the pit.

The liquid trapped underneath can undergo reactions that increase the acidity, which increases the corrosion potential.

Chlorides or other anions diffuse into the pit to try to maintain charge neutrality, however, acidic conditions often remain. The deposits above the pit prevent bulk water corrosion inhibitors from re-passivating the metal surface within the pit.

The following figures illustrate additional pitting examples.

7.11a is pitting that has penetrated the metal basin of a cooling tower. 7.11b shows corrosion products on the outside of a pipe that was generated by internal attack and resulting through-wall penetration. 7.11c illustrates another through-wall penetration.

For carbon steel pits covered or filled with corrosion products, if the material is black (typically due to the presence of magnetite (Fe3O4)), the pit is active and the corrosion process is ongoing.

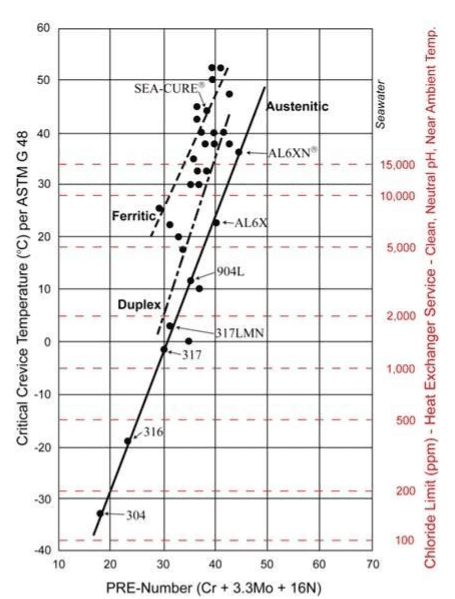

Chloride pitting of stainless steels is a frequent problem, including in open recirculating systems where cooling tower evaporation (see Chapter 6) increases the dissolved solids concentration. The two most popular stainless steels (SS) for steam surface condenser tubes are 304 and 316, and often one or the other is specified for a project without the designers giving much, if any, thought to the chloride concentrations the materials will see. The difficulty is that stainless steels form an oxide coating that protects the base metal, but chloride in sufficient concentration will penetrate the oxide layer and initiate pitting. For years, the recommended maximum chloride levels for these steels ranged from 500 ppm for 304 SS to 3,000 ppm for 316L SS at ambient temperature. Research has subsequently shown that these limits were too high, and one noted materials expert suggests 100 and 400 ppm, respectively, for clean tubes. Note the emphasis on clean tubes. Deposits exacerbate the corrosion potential. Also, temperatures above ambient greatly influence the potential for chloride-induced stress corrosion cracking (SCC) of austenitic stainless steels, which can be of huge concern in industries such as petroleum refining that have many heat exchangers for production of numerous compounds. SCC is examined shortly.

Resistance to chloride pitting is often a primary factor in heat exchanger materials selection. A well-known guide is the pitting resistance equivalent number (PREN) chart as shown below.

Higher-alloy materials beyond the 300 austenitic stainless series are recommended for cooling waters with appreciable chlorides. For highly brackish waters and seawater, the ferritic and super-ferritic alloys, e.g., SEA-CURE®, are often required.

Crevice Corrosion

Crevice corrosion is a mechanism that develops at the crevices of mechanical joints, e.g., flange gaskets, the rolled ends of tubes, bolt connections, or at other locations including the boundaries of deposits. Figure 7.13 shows an example of crevice corrosion.

Water stagnates in these locations and can become oxygen depleted, which then makes the crevices anodic to the other metal. Like pitting, the corrosion is localized.

Often, crevice corrosion is not discovered until a scheduled outage or if the corrosion causes an equipment failure. The best approach to avoid crevice corrosion is to eliminate the crevice. Proper chemical treatment will minimize deposit and crevice formation from that source, but for equipment that is mechanically coupled, care is needed in the design phase to eliminate crevices when possible. For example, installing water-impermeable gaskets at flange connections may be a solution in some applications.

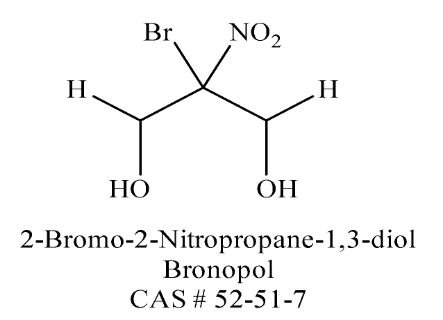

Manganese Influenced Pitting

A phenomenon that has plagued numerous water-cooled heat exchangers is manganese-influenced pitting, with many problems reported along the Ohio River. Even at concentrations as low as 0.02 ppm, dissolved manganese in cooling water can be oxidized to manganese dioxide (MnO2) by chlorination. A thin, varnish-like coating will appear on the heat exchanger surfaces.

The manganese deposits are strongly cathodic to the underlying metal, and can cause severe localized corrosion.

304 and 316 SS are very susceptible to manganese deposit corrosion, but it can also affect admiralty brass, aluminum brass and cupro-nickel. Attack is likely if the manganese content of the deposit exceeds five percent. A concentration greater than 20 percent will result in severe pitting.

Other factors that induce MnO2 formation include elevated pH, aeration, and sometimes catalytic influences by the metal surface itself. Furthermore, the MnO2 layer can be oxidized to permanganate (MnO4) by chlorine. Permanganate dissolves the base metal, and in the process is reduced back to MnO2. The cycle repeats during each chlorination. Manganese corrosion is apparently not a major problem with mild steel, possibly because other corrosion products prevent manganese from forming a uniform and dense deposit.

Manganese deposition and corrosion control methods include limiting or eliminating oxidizing biocide feed (potentially by switching to non-oxidizing biocides), and application of an effective manganese stabilization program. Selection of corrosion-resistant materials in the design phase is another approach.

Erosion Corrosion

If the cooling water contains significant suspended solids, gas bubbles, or if the velocity is simply too high, the flowing fluid can strip the protective oxide layer on metals and allow continuous corrosion.

For example, in one flow study of seawater on mild steel, the following corrosion rates were measured:

Table 7-A: Linear Velocity and Corrosion Rates of Seawater on Mild Steel

| Linear Velocity (ft/sec) | Corrosion Rate (mpy) |

| 1 | 7 |

| 4 | 15 |

| 17 | 35 |

Soft metals such as Admiralty brass are the most susceptible to erosion, especially at flow disturbances such as the inlet end of heat exchanger tube sheets. These issues must be accounted for during project design.

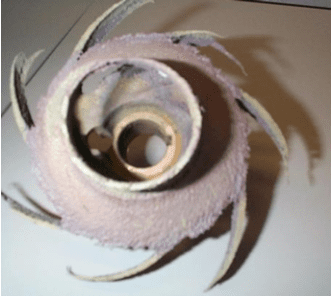

Cavitation

Cavitation is a specific type of erosion corrosion that most commonly affects centrifugal pump impellers.

If insufficient pressure is available at the pump suction (inlet pressure is termed “net positive suction head (NPSH)”), bubbles in the water may collapse. The collapsing bubbles can generate very large localized forces that strip protective oxide and damage the metal. Other potential locations for cavitation include valve discharge, regulators, orifices, or other locations of pressure drop. Potential cavitation issues should be addressed in the project design phase to ensure that pumps and other equipment have sufficient head pressure.

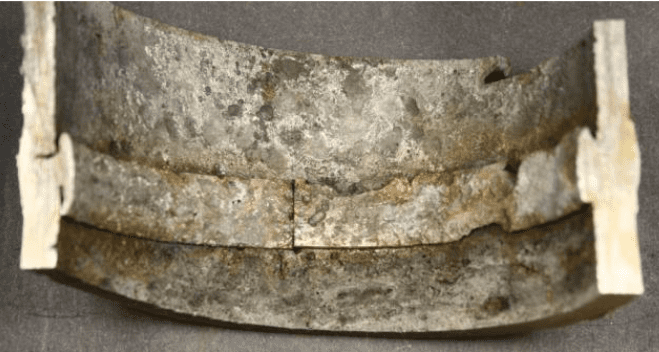

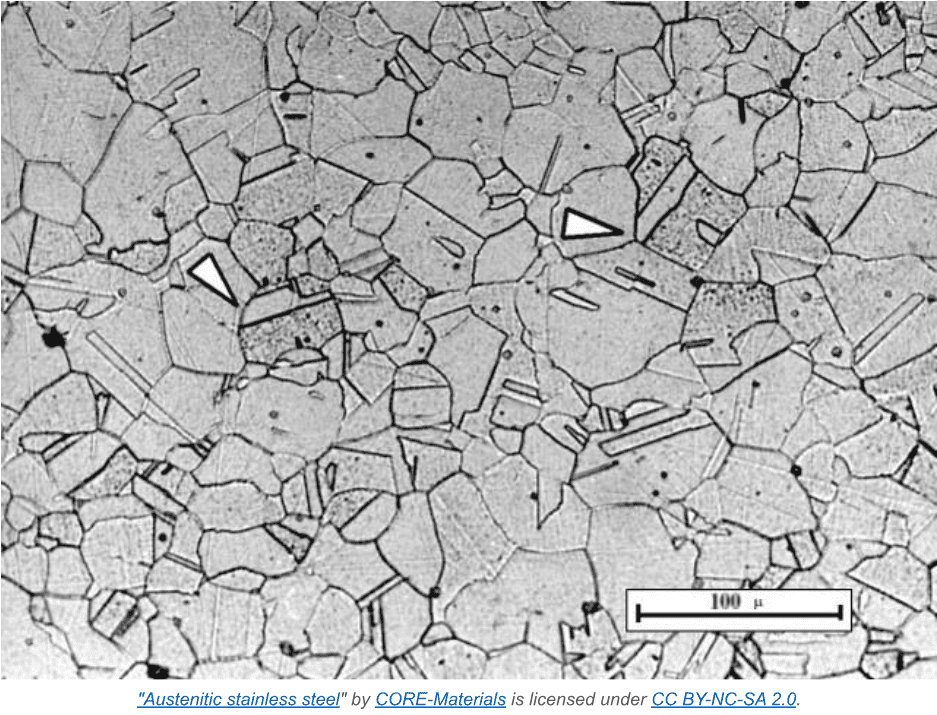

Fatigue, Corrosion Fatigue, and Stress Corrosion Cracking

Virtually all metals utilized in conventional applications such as piping, heat exchangers, and other equipment are not one single crystal, but, per reference 1, “are composed of a collection of many small crystals or grains.” The grain structure has a huge impact on metallurgy and several corrosion mechanisms.

A straightforward example of fatigue is readily demonstrated by bending a paperclip or piece of wire back and forth repeatedly until it fractures. The fractures often align along grain boundaries. Plant equipment that repeatedly cycles in load may suffer from fatigue. The corrosion typically begins as micro-fissures that grow larger over time. Research suggests that fatigue can also frequently occur across grains, i.e., transgranular.

Fatigue may be accelerated if the metal is immersed within a corrosive environment, even basic process waters. As fissures develop, corrosion products (often just oxides of the base metal) can build up within the cracks and exacerbate crack growth. This is corrosion fatigue.

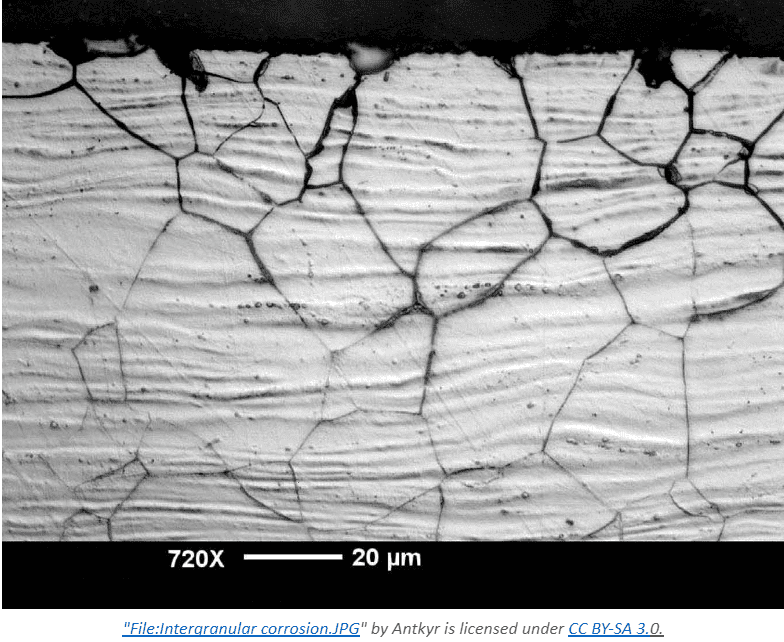

Other intergranular corrosion mechanisms beyond fatigue may be quite problematic, as relatively small metal loss can cause a disproportionate reduction in metal strength.

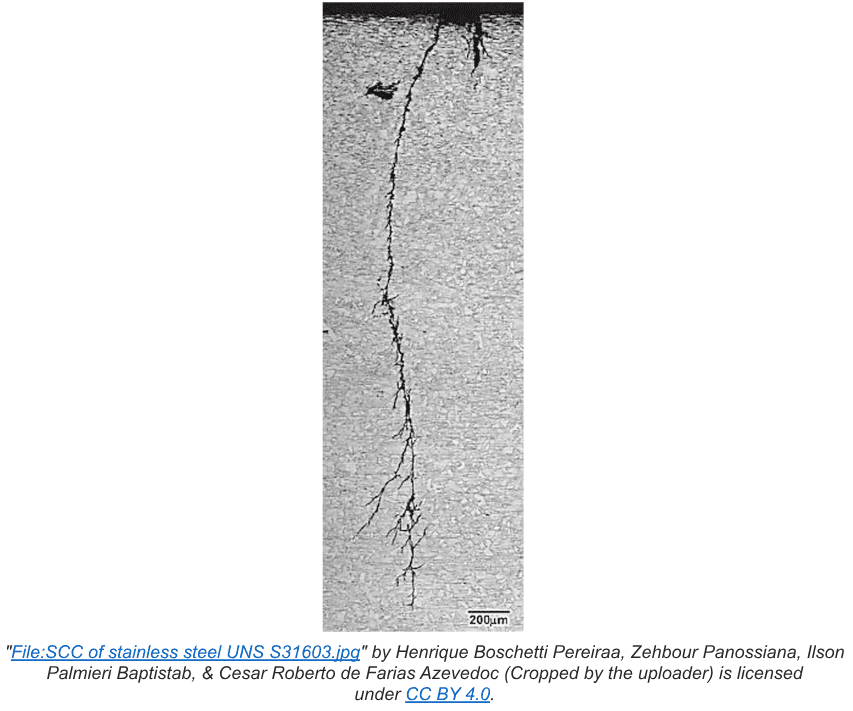

Intergranular corrosion is a localized attack that occurs at the grain boundaries, where relatively little metal loss can cause a disproportionate reduction in metal strength. The most well-known mechanism is stress corrosion cracking (SCC), and it can be particularly troublesome in high-temperature applications. (See Chapter 4).

SCC requires some type of metal stress, but where the stress can be either internal or applied.

Internal stress usually appears during the fabrication process. A common example of applied internal stress is cold work or cold rolling of steel to shape it for a particular specification. Seamed pipe is a well-known example. Heat treatment/annealing is often utilized to relieve stresses induced by cold working.

Weak spots generated by stress can develop into micro-fissures that then become susceptible to corrosive agents in the water. Perhaps the most well-known example is chloride-induced SCC of stainless steel. At stress points, anodes develop, which are surrounded by non-stressed metal that serves as the cathode.

Common locations for SCC in cooling water systems include threads cut into nuts and bolts, rolled tubes at tube sheets, drilled or punched holes in distributor piping, and pipe elbows where the metal has been mechanically worked.

SCC can be mitigated by heat treatment stress relief. However, it is not always practical to heat relieve every potential location. During equipment inspections, identified or suspected stressed material should receive special attention to determine the efficacy of chemical treatment programs in minimizing corrosion.

Intergranular and stress corrosion susceptibility is often greater at welds. For chromium-alloy steel, the welding process can cause the precipitation of chromium carbides that generate chromium depleted spots within the metal. These become anodic to the base metal and become susceptible to localized corrosion. Many failures have occurred at weld seams in plant water systems. Selection of the correct weld filler material is also important. An under-recognized problem is use of a filler material that has different thermal expansion properties than the base metal. Mechanical fracture may result.

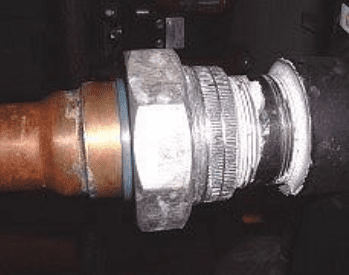

Galvanic Corrosion

Galvanic corrosion occurs when two different metals are in physical contact within the cooling water environment. Hearken back to Table 7-1, which outlined the electrochemical potentials for several of the most common metals for cooling water infrastructure. If two metals are coupled, the more reactive of the two will become anodic to the less reactive. The larger the separation in electrochemical potential, the greater the potential corrosion rate. A classic example is shown in the figure below.

Sometimes galvanic cells may develop per chemical reactions that occur within the fluid. The manganese pitting corrosion mechanism outlined earlier was one example. Another common mechanism occurs in systems that have both steel and copper alloys, even if they are not physically connected. If the conditions allow some copper corrosion, the copper may plate out on the steel and produce a galvanic corrosion cell.

This example provides an excellent application of data from Table 7.1 by examining the reaction via the half-cell potentials.

Fe → Fe2+ + 2e–

Cu2+ + 2e– → Cu

V0 = 0.440V

V0 = 0.340V

E0 = 0.780V

A strong driving potential exists for this reaction.

The ideal solution to galvanic corrosion is to not have mixed metallurgies in cooling systems, but this arrangement is usually impractical. A key is having a small ratio of the more electronegative material, e.g., copper, in a system with a much larger amount of the electropositive material, e.g., steel. While galvanic corrosion can still occur, the large anode to cathode ratio ensures that the attack is spread out over a large area and does not cause severe damage.

In other cases, special fittings or connections may be employed to physically separate different metals.

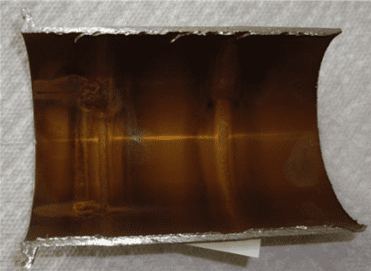

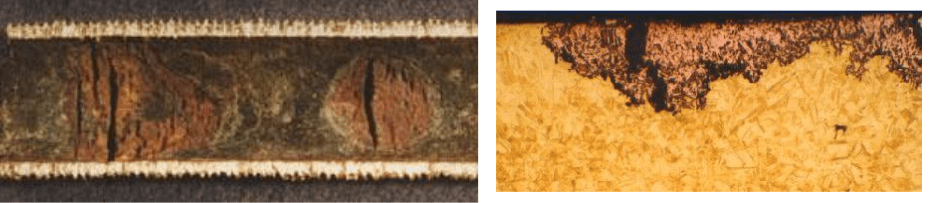

Dealloying

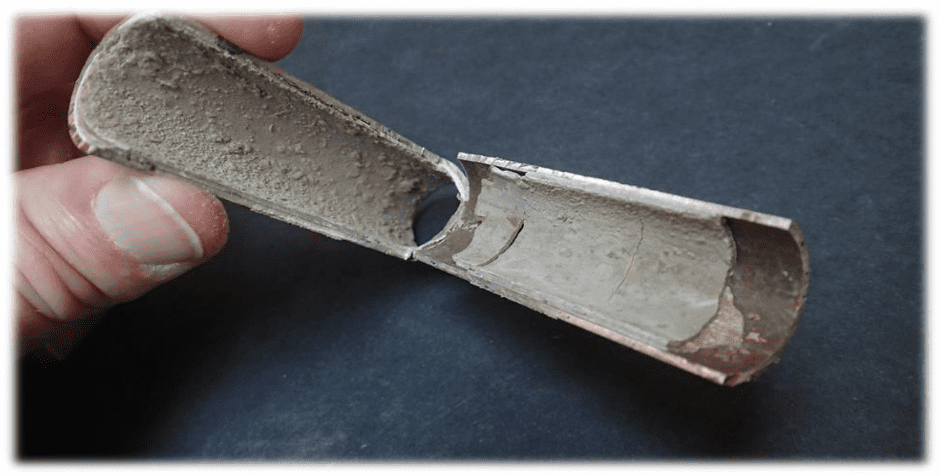

A unique form of corrosion that sometimes occurs in heat exchanger tubes is dealloying. The most common example is dezincification of admiralty brass. Admiralty brass contains 70 percent copper, 29 percent zinc, and small amount of tin, the latter to help minimize dezincification. Even so, dezincification may still occur. Figure 7.24 shows an admiralty tube that has experienced zinc loss.

Two types of dezincification have been postulated; plug and layer. In either case, zinc departs from the metal substrate resulting in porous and brittle copper that is not structurally sound. Visually, the attack appears as a dull red patch on the yellowish copper metal.

The actual dezincification mechanism is still highly debated. One theory is that both metals corrode, with copper redepositing. The other is that zinc selectively leaches out of the alloy. The following conditions can enhance dezincification:

- Chlorides >350 ppm

- Halogen residuals >1 ppm

- TDS >3,500 ppm

- pH >8.3

- Temperature >120o F

Another dealloying mechanism that has been reported on rare occasions is denickelification of copper-nickel alloys. This phenomenon appears to be quite infrequent, and will not be discussed further in this book.

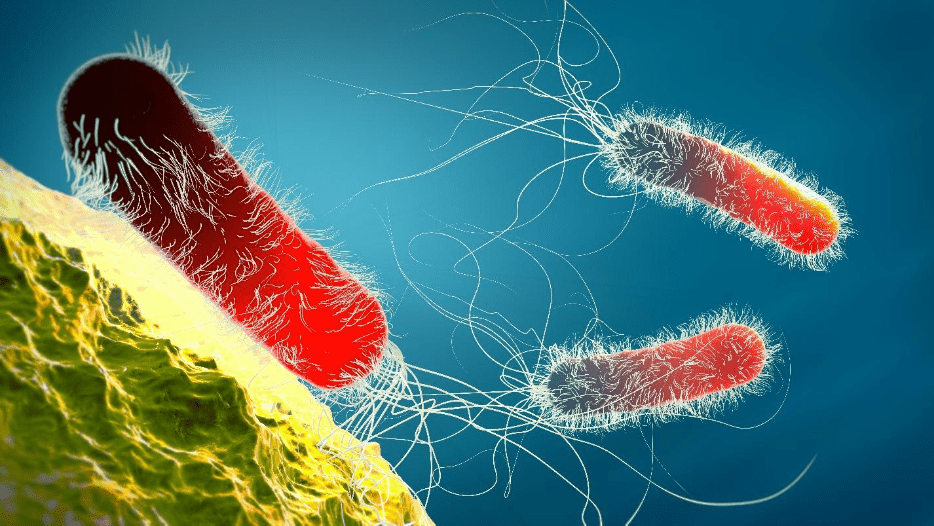

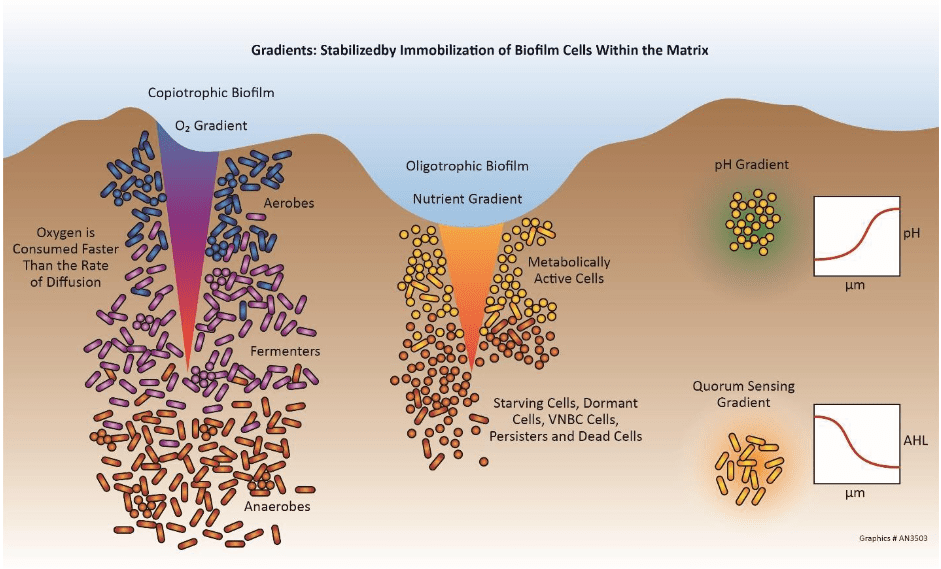

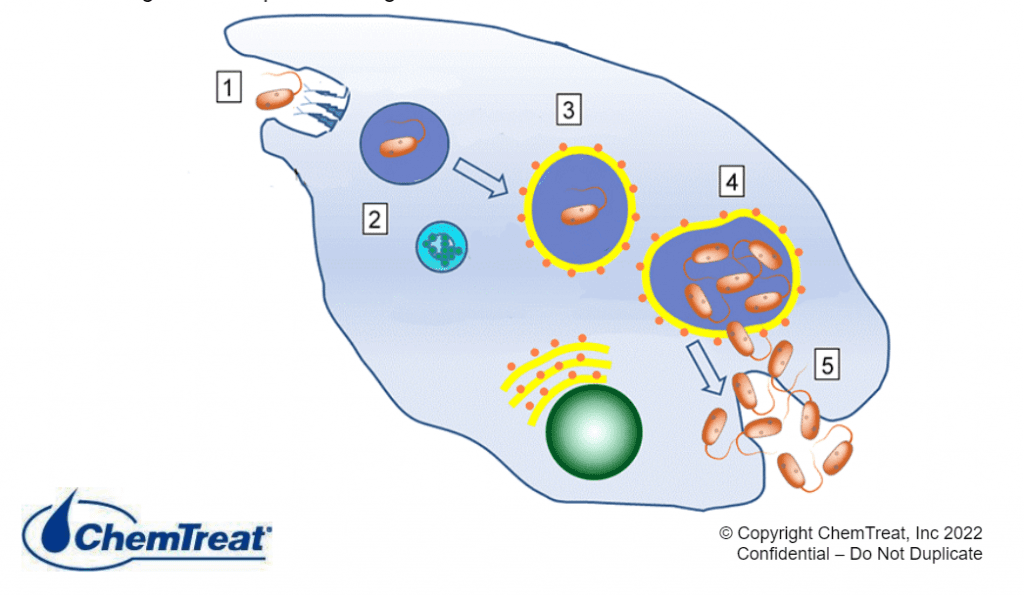

Microbiologically Induced (Influenced) Corrosion

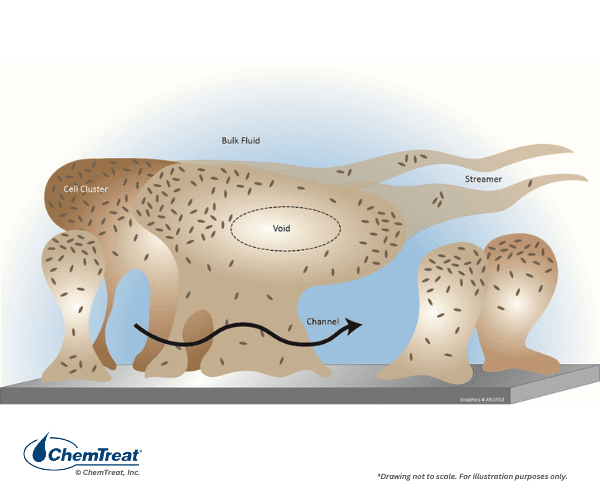

Microbiologically induced corrosion (MIC) is a process in which microorganisms initiate, facilitate and/or accelerate corrosion reactions. Cooling systems provide an ideal environment for microorganisms to establish colonies and form slimy, mud-like deposits. (Additional details are provided in the microbiological control section later in this chapter.) In the first place, deposits can cause oxygen differential corrosion as outlined earlier. Beyond this issue, however, is that the metabolic processes of some microbes generate compounds that directly attack metals. For example, iron-oxidizing bacteria such as gallionella produce ferric chloride, which is known to accelerate pitting. Sulfate reducing bacteria (SRB) such as desulfovibrio desulfuricans extract oxygen from sulfate (SO4) to produce hydrogen sulfide (H2S). Sulfides in just about any form are quite corrosive to many metals.

MIC can leave smooth gouges in the metal surface as shown in Figure 7.25 below, and it can also cause rapid pitting of some materials, including stainless steels.

Corrosion of Non-Ferrous Metals and Non-Metals

So far, much of the discussion has been about steel corrosion, as steels make up most of the metal in cooling systems. However, other metallic and non-metallic materials are often present, and these can suffer from corrosion, too. The next sections examine corrosion issues for the most common of these materials.

Copper Alloys

Copper alloys are often the second most common material in cooling water systems, typically for heat exchanger tubes. Copper alloys have a higher thermal conductivity than steel, are naturally toxic to many aquatic species, and are more resistant than steel to some corrosion mechanisms.

As Table 7.2 indicated, copper is noble with respect to the hydrogen ion, and thus does not tend to corrode in acids. However, oxygen is more reactive than H+, and in cooling water systems copper alloys will initially develop a cuprous oxide (Cu2O) multi-layer of variable porosity, where copper exists in the +1 valence state.

- 2Cu + O2 → Cu2O | Eq. 7-9

Over time, and in the continued presence of oxygen or other oxidizing agents, further oxidation of the outer cuprous oxide layer can take place to produce a grayish-black layer of cupric oxide (CuO).

- Cu2O + ½O2 → 2CuO | Eq. 7-10

In some cases, the cupric oxide layer may remain protective, but certain compounds, and most notably ammonia, can be very corrosive. It dissolves cupric ion through a mechanism known as d-orbital bonding.

- Cu2+ + 4NH3 → Cu(NH3)42+ (aq) | Eq. 7-11

For makeup waters containing a significant concentration of ammonia, e.g., wastewater treatment plant effluent, corrosion of copper-alloy condenser or other heat exchanger tubes may be of significant concern. Copper-alloy corrosion has sometimes been problematic in steam systems where ammonia is utilized for condensate and feedwater pH control.

Another impurity that can cause enormous damage to copper alloys (and other metals) is sulfide, which, as has been noted may come from microbiological colonies that contain sulfate reducing bacteria.

- Cu2+ + H2S → CuS↓ + H2↑ | Eq. 7-12

Other potential sulfide sources include water that has been allowed to go septic, and from process leaks at refineries and similar plants. A startling example occurred a number of years ago, when the aging 90-10 Cu-Ni tubes in a steam surface condenser were replaced, only to have the new tubes fail from pitting attack within 18 months of commissioning. Investigation revealed that the tube fabricator utilized a lubricant containing sulfide, but did not remove the compound before shipment to the plant. The sulfide deposits did not wash off, but rather burrowed into the metal in thousands of spots.

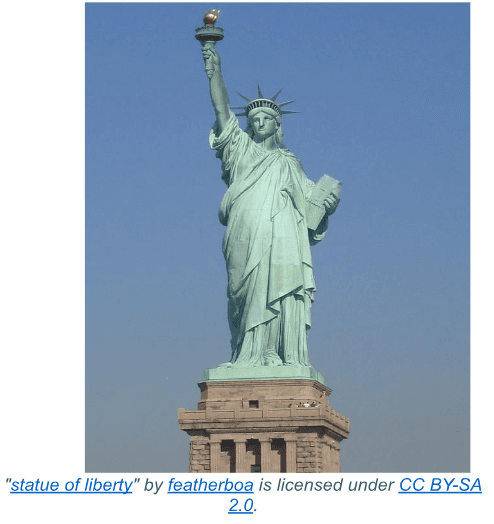

A different but very recognizable copper corrosion product is copper carbonate (CuCO3). This bluish/green verdigris (also called patina) is often seen on weathered copper-alloy structures such as roofing, plaques and statues, and is typically part of the architectural design of the structures.

The basic chemistry is:

- 2Cu + H2O + CO2 + O2 → Cu(OH)2 + CuCO3↓ | Eq. 7-13

The color can be somewhat variable depending upon the degree of hydration of the film.

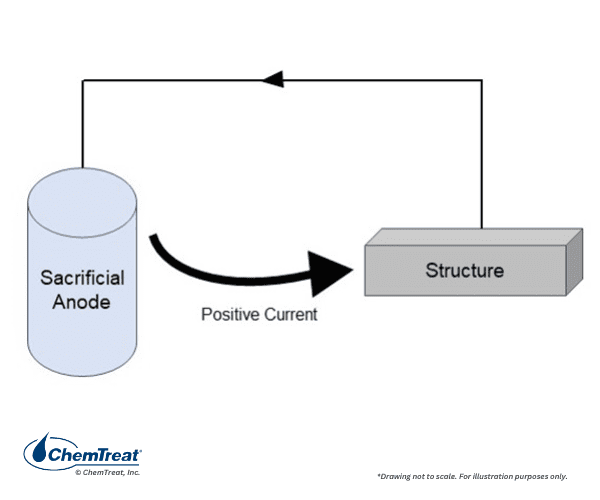

Zinc

Referring again to Table 7.2, zinc is anodic to almost all metals except magnesium and aluminum. Unlike those two metals, though, it does not form a super-strong oxide layer. Rather, via the galvanizing process where a zinc coating is applied to steel surfaces, the zinc serves as a sacrificial anode to iron.

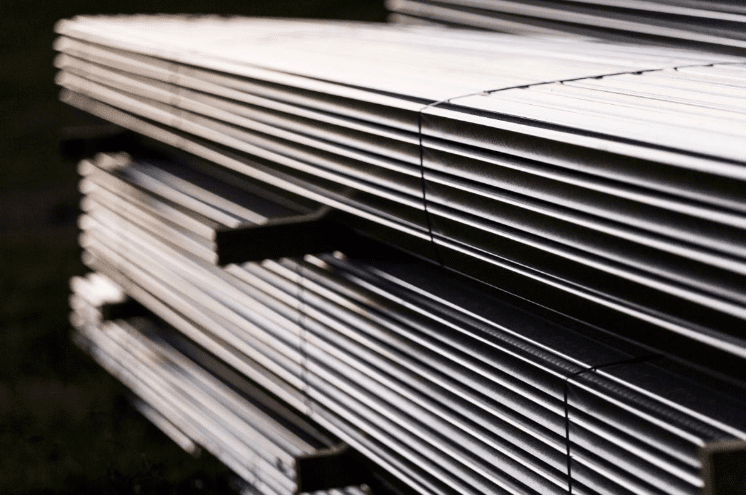

Galvanizing has been in use since 1742. Much modern galvanizing is by hot dipping, although continuous processes such as heavy mill galvanizing are common for sheet steel. Hot dipping is a batch process in which newly fabricated steel components are immersed in a solution of molten zinc for a prescribed time. The zinc fuses to the steel surface. The coating thickness is directly proportional to the immersion duration, which can be adjusted per component size and application.

Newly galvanized materials are often shiny and very reflective as shown in Figure 7.27.

However, not all galvanized coatings are shiny. Some elements in the steel, e.g., silicon and phosphorous, can accelerate the growth of zinc-iron alloy layers. This may produce a finished galvanized coating consisting entirely of zinc-iron alloy.

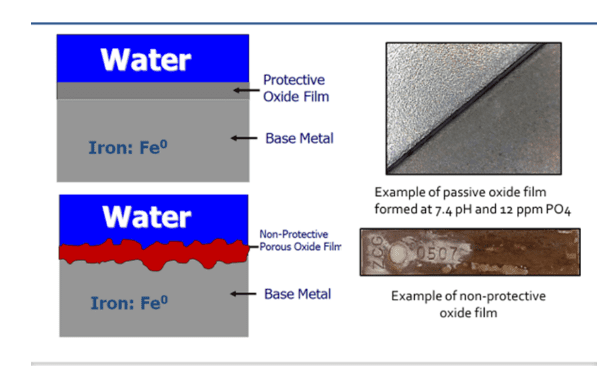

The formation of the protective dark gray patina (surface finish) begins with the development of a thin layer of zinc oxide on the surface. Under proper conditions, these oxides will incorporate a layer of basic zinc carbonate when in contact with water. Following initial exposure to water and carbon dioxide (which can be achieved by allowing new galvanized cooling system components to experience outdoor conditions over a period of several months), industrial galvanized components can then be exposed to system water. The conditioning step requires careful control to produce a hydrated zinc carbonate compound thought to have the following formula:

- 3Zn(OH)2∙ZnCO3∙H2O

This layer grows and becomes more protective over time, but if the proper water chemistry is not established during the conditioning process, a non-protective material known as “white rust” can form. Further details regarding zinc passivation chemistry are examined in a later section on pre-operational startup of cooling systems.

Galvanized components are common in many cooling tower locations, even if the main support structure is wood or plastic.

Many commercial cooling towers of modest size may be completely fabricated from galvanized steel.

Aluminum

When thinking back to Table 7.1 at the beginning of this chapter, it is hard to imagine that aluminum, and, in some cases, magnesium, are suitable for construction purposes, as they are so reactive. The key is that the high reactivity induces formation of a tight oxide layer that protects the metal underneath. Typical aluminum products include injection molds, engine blocks, radiators, cooling tower ladders and walkways, handrails, fan blades and other similar components. Aluminum is resistant to atmospheric corrosion and that aspect, coupled with its light weight, make it an excellent material for airplane components.

Aluminum is an amphoteric material meaning that it will corrode at low and high pH.

Aluminum can corrode in waters made alkaline with phosphate. Also, because aluminum is the more active electrochemically than steel, it will corrode when coupled to steel in cooling water environments.

Non-Metallic Corrosion Issues

This section briefly examines two non-metallic corrosion issues primarily related to large cooling towers. These are the degradation of wood (which may serve as the tower support structure), and concrete, which is a common material for cooling tower basins.

Wood Degradation

For those many large cooling towers that still have wooden components, this section provides an overview of degradation influences. Wood deterioration can generally be classified into three categories, physical, chemical, and microbiological.

- Physical

- Excessively elevated cooling water temperatures greater than 140o F

- Ice damage

- Erosion

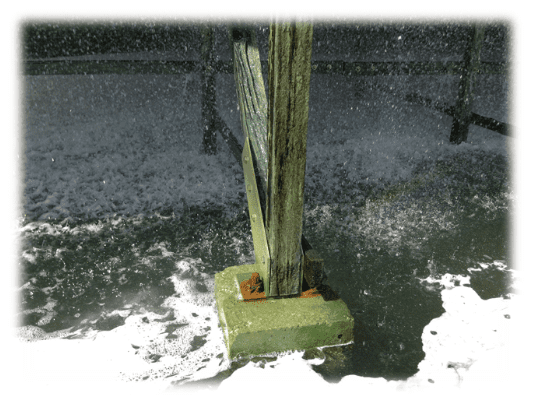

- “Iron rot” from adjacent rusting metal fasteners (Figure 7.30)

- Wet/dry cyclical damage

- Mechanical Stress (Figure 7.31)

- Chemical

- Elevated chlorine concentrations exceeding 1.0 ppm, which can delignify the wood. Lignin is the binder for cellulose fibers in wood, but can be destroyed by a high halogen content.

- Chemical injection lines placed near wooden structures. If these lines develop leaks, the concentrated chemicals can attack wood.

- High pH values above 9.0. Elevated pH can be especially destructive when combined with high chlorine concentrations. Cooling water treatment programs are typically designed to operate below this pH.

- Biological (principally fungi-related)

- Fungi are responsible for wood decay and destruction

- Fungi exist as yeasts (unicellular) and molds (multicellular-filamentous)

- Fungi thrive in a slightly acid pH range of 5.5–6.5.

- Fungi require high levels of organic carbon, as compared to bacteria. It follows that bulk water fungi proliferation is relatively rare, unless organic contamination is present, perhaps from hydrocarbon process leaks or if the makeup supply is municipal wastewater treatment plant effluent.

The following discussion outlines the three primary types of fungal wood rot.

Brown Rot: Brown rot, also known as dry rot, is more common in soft woods, and attacks beneath the preservative layer applied during fabrication. The fungi go after cellulose, leaving dark-colored lignins behind. It can penetrate deep into the wood.

White Rot: White rot is more common in hard woods, and attacks lignins. It progresses more slowly than brown rot. The wood surface becomes soft and stringy, and appears bleached. White rot can be controlled by surface fungicide treatments in early growth stages. The fungicide penetrates slowly into the wood.

Soft Rot: Soft rot occurs only in water-washed areas and is confined to the surface in early stages. The attack is slower than white or brown rot. The surface appears cracked and light-colored when dry. Soft rot can be controlled by diligent cooling water microbiological treatment.

Concrete Corrosion

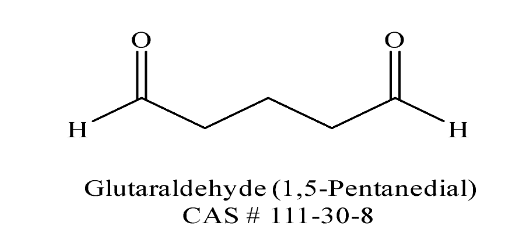

Concrete was the material of construction for the large hyperbolic cooling towers at nuclear plants and some coal plants in the last century. Virtually no hyperbolic towers have been constructed in the last several decades and will not be considered further here. However, many of the large, mechanical draft towers in heavy industry and power have reinforced concrete basins.

Concrete is strong, poured on site, and can have a long life. A common problem over the years has come at plants where sulfuric acid is utilized for cooling water pH control, and where the acid is not diluted prior to injection into the basin. Commodity-strength sulfuric acid (93–98 percent concentration) has a density almost twice that of water, and will sink rapidly to the basin floor if not diluted, where it can attack the concrete and concrete-reinforcing bars.

The primary method to minimize such damage is an acid dilution system, which externally mix acid and water, with distribution of the mixture through a trough above the basin.

Standard Portland cement can be attacked by waters with a high sulfate concentration (>1,500 ppm), which is possible in some cooling systems per the concentrating effect of the tower. This issue can be addressed in the design phase with careful calculation of the makeup water quality and the extent to which sulfate will concentrate when the tower is cycled up to normal levels. Conditions may require the use of Type V Portland cement, which has a reduced amount of tri-calcium aluminate, ordinarily one of the primary components of standard cement.

Before examining corrosion control methods, we will look at the primary causes of deposition and scaling in cooling systems. Past and present water treatment programs are usually blends of corrosion and deposit inhibitors, and thus discussion of one often includes the other.

Deposition Mechanisms

Apart from scale formation, solids deposition in cooling systems can occur by several additional mechanisms, including:

- Settling in restricted-flow areas

- Contamination from airborne particulates that enter the cooling tower

- Microbiological foulings

- Macrobiological fouling

- Fouling from grease and oil or other organic process contaminants

- Corrosion products from other areas of the system

Restricted-Flow Issues

One common restricted-flow location, outlined in Chapter 6, is cooling tower fill.

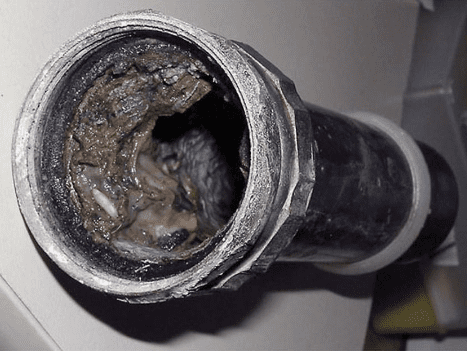

High-efficiency film fill provides excellent heat transfer but at the price of a torturous flow path that reduces water velocity. Throttled flow to heat exchangers can also establish low-flow zones that collect solids. An often-overlooked item with large cooling systems are dead legs that can accumulate materials, including microbes.

Airborne Particulates

Cooling towers are superb air scrubbers, and many solids may be introduced via that flow path. Dust ingression during dry periods is a common problem. Another classic example with which many operators are familiar is intrusion of cottonwood seeds and additional leafy vegetation that clog strainers and other equipment.

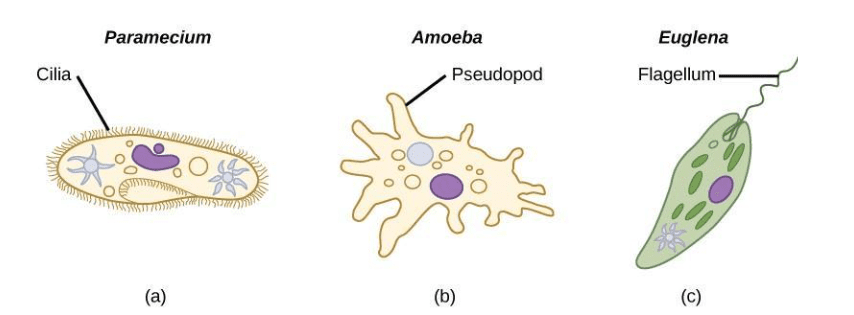

Microbiological Fouling

Water and air are filled with microbes that can potentially form troublesome colonies throughout cooling systems. Fouling can occur very rapidly and potentially force unit derating or even equipment shutdown within days of the microbial onset. The protective slime secreted by some microbes easily traps suspended solids that convert the material into a mud-like product.

Macrobiological Fouling

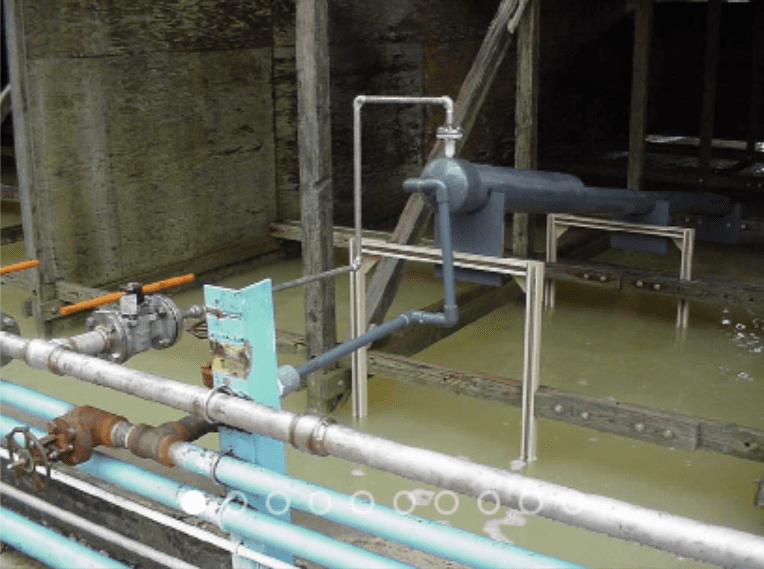

A number of aquatic creatures that escape cooling water inlet screens can block the inlet ends of heat exchanger tubes. These difficulties have been particularly problematic in once-through power plant steam surface condensers. Some of the most common creatures include Asiatic clams, zebra mussels, and even small fish such as shad.

Process Contaminant Fouling

Many large industries have numerous heat exchangers. Heat exchanger leaks may introduce contaminants to the cooling water return to the tower. Particularly troublesome are oils and heavy hydrocarbons that can coat cooling system equipment.

Corrosion Product Deposition

Corrosion is problematic in its own right, but corrosion releases products that then lodge in other locations.

Scale Formation

Chapter 1 included a discussion about solubility products, and how when various dissolved ions reach a solubility limit, solids precipitation occurs. This is the mechanism behind scale formation in water systems.

In Chapter 2, we learned that the most common precipitate in natural waters is calcium carbonate (CaCO3), and how CaCO3 precipitation chemistry can be used advantageously in lime softening reactions for makeup water treatment. Conversely, the unwanted formation of calcium carbonate scale in water systems, including home plumbing, has plagued humankind for years, and whose treatment launched the modern scale-control chemistry we know today. To review briefly, almost all natural waters contain dissolved calcium ions (Ca2+) and bicarbonate alkalinity (HCO3–). Per various influences, including temperature, the ions will precipitate from solution. The following reaction is representative of this process.

- Ca2+ + 2HCO3– + heat → CaCO3↓ + CO2↑ + H2O | Eq. 7-14

Calcium carbonate has three polymorphs. Calcite is the thermodynamically most stable form, and comprises most natural deposits.

A less stable form is aragonite, which is mainly found in biosynthetic CaCO3 such as shells and corals. The final structure is vaterite, which rarely occurs in nature, but plays an important transitional role in calcium carbonate formation from solution.

Calcium carbonate deposition was the driver for the development of the first programs to predict scale-forming (and corrosion) tendencies of water impurities. These developments are highlighted below.

Saturation Indices

Langelier Saturation Index (LSI)

In 1936, Dr. Wilfred F. Langelier (1886–1981) was researching a corrosion problem in the water supply piping for Cleveland, Ohio. He learned that corrosion could be reduced by raising the treated water pH, but with the tradeoff of increased potential for calcium carbonate scaling.

He developed the LSI; an equilibrium model derived from the theoretical evaluation of calcium carbonate saturation. A water is said to be at saturation with calcium carbonate when it will neither dissolve nor precipitate the mineral. His calculations could predict when calcium carbonate scaling would occur by measuring the concentrations of calcium, bicarbonate alkalinity, pH and total dissolved solids, throughout the common water temperature range.

The fundamental equation is:

- LSI = pH – pHs | Eq 7-15

Where;

- pH = The actual measured pH

- pHs = The pH of calcium carbonate saturation. It is a calculated value where the calcium carbonate in solution is in equilibrium with precipitated calcium carbonate.

- pHs = (pK2 ‒ pKs) + pCa + pAlk Eq 7-16

- pK2 = negative log10 of the second dissociation constant for carbonic acid; pKs = negative log10 of the solubility product (Ksp) for calcite (CaCO3); pCa = negative log10 of the calcium concentration; and pAlk = negative log10 of the total alkalinity concentration.

- pHs = (pK2 ‒ pKs) + pCa + pAlk Eq 7-16

The values for pK2 and pKs are a function of temperature. As the LSI technique gained favor, researchers developed nomographs that allowed quick calculation of (pK2 ‒ pKs) within typical once-through or open-recirculating temperature ranges.

The empirical correlation of the calculations is summarized as follows:

- LSI <0, calcium carbonate scale will dissolve and the potential exists for mild steel corrosion.

- LSI = 0, the water is stable with regard to calcium carbonate formation and dissolution.

- LSI >0, the potential for calcium carbonate scale formation increases with increasing LSI.

Langelier was able to control corrosion while avoiding scale formation by adjusting lime feed to maintain a +0.5 to +1.0 LSI range in the city water.

For once-through and closed water systems, alkali addition to increase the LSI to 0.5 or thereabouts can minimize corrosivity but not reach severe scale-forming conditions. In a recirculating cooling system, it may be possible to raise the LSI or the other indices outlined below by increasing the cycles of concentration, which increases the calcium hardness and carbonate alkalinity.

Ryznar Stability Index (RSI)

In 1944, John W. Ryznar (1912–1996) proposed a substantial modification to the LSI. He found that it was possible for both low hardness and high hardness waters to have the same LSI depending on the alkalinity and related pH. Ryznar named his relationship the Stability Index, and substantiated his RSI with experimental data. The Ryznar equation employs the same data as the LSI, but the final calculation is:

- RSI = 2pHs – pH | Eq 7-17

The empirical correlation of the RSI is summarized as follows:

- RSI < 6, calcium carbonate scale tendency increases as the index decreases.

- RSI = 6, the water is stable with regard calcium carbonate formation and dissolution.

- RSI > 6, calcium carbonate scale will dissolve and mild steel corrosion becomes an increasing probability with increasing values.

Practical Scaling Index (PSI)

The Practical Scaling Index (PSI) was developed by Paul Puckorius (1930 – 2019), who, when young, was an assistant of Ryznar’s. It incorporates a calculated pH of the water based on buffering capacity, instead of simply measured pH. The practical scaling index (PSI) equation is:

- (PSI) = 2(pHs) ‒ pHeq | Eq. 7-18

- pHeq = 1.465 x log10 (total alkalinity) + 4.54 | Eq. 7-19

The PSI empirical correlation is the same as RSI. At least one of the major combustion turbine manufacturers utilizes PSI for calculation of scaling tendencies for inlet air coolers. Placing the calculations in a spreadsheet program is straightforward.

Other predictive indices are available, including the Oddo-Tomson Index, Stiff-Davis Index, Saturation Levels, Momentary Excess, and others. It is helpful at this point to introduce one other calculation, the Larson-Skold index for corrosion potential. Aggressive anions like chloride and sulfate are more electrically conductive than the buffering anions, bicarbonate and carbonate. In the 1950s, Dr. T. E. Larson and Dr. R. V. Skold studied the corrosivity of Great Lakes waters, and developed the following formula.

- Larson-Skold Index = (epm Cl– + epm SO42-)/(epm HCO3– + epm CO32-) | Eq. 7-20

(epm = equivalents per million)

They found that when the ratio of strong anions to weak anions was less than 0.2, the buffering anions have a greater influence than the corrosive anions, and can form a natural inhibitive film. However, when the index rises above 0.6, the situation is reversed and the potential for corrosion is greater. The Larson-Skold empirical relationship was specifically based on Great Lakes waters. Although similar relationships can be calculated for other waters, the predictions may be different.

While some water treatment companies still use these calculations for quick evaluation of water scaling tendencies, the methods lack the capabilities of modern computer programs, which account for additional factors including the common ion effect. Quite sophisticated programs are available that allow the user to input not only system conditions and raw water chemistry, but actual scale inhibitor types and concentrations. The programs will calculate normal range and boundary conditions for any desired treatment program. The next sections examine additional scaling mechanisms.

Other Scales

Depending upon the chemistry of the makeup water, or how it changes when cycled up in a cooling tower, other mineral deposits are possible in cooling systems. Table 7-2 outlines the most common.

Table 7-2. Other Common Cooling Water Scale Deposits

| Compound | Formula |

| Gypsum | CaSO4∙2H2O |

| Silica | SiO2 |

| Magnesium Silicate | MgSiO3 |

| Calcium Phosphate | Ca3(PO4)2 |

| Fluorite | CaF2 |

As will be shown, some scaling issues, and most notably those related to sulfate and phosphate deposition, in large measure emerged from advancements to or changes in chemical treatment programs.

Before proceeding, an important point should be highlighted regarding the mineral compounds in Table 7-2 as compared to CaCO3. The anion in calcium carbonate is CO3. In alternative chemistry terms, CO3 is the “conjugate base” of the weak acid H2CO3. A discussion of conjugate acids and bases is beyond the scope of this book, but the key idea is that carbonate deposits can usually be removed by acid application, even in dilute form.

- CaCO3 + H2SO4 → Ca2+(aq) + SO42-(aq) + H2CO3 | Eq. 7-21

- H2CO3 ⇌ CO2↑ + H2O | Eq. 7-22

Thus, if acid is supplied in sufficient quantities with uniform contact, CaCO3 deposits will entirely dissolve as the carbonate converts to carbon dioxide. Sulfuric acid feed to cooling tower makeup was, and in some cases still is, a common method to reduce alkalinity and lower the potential for CaCO3 scale formation. Acid feed requirements are often not large enough to cause calcium sulfate precipitation, but the issue cannot be ignored.

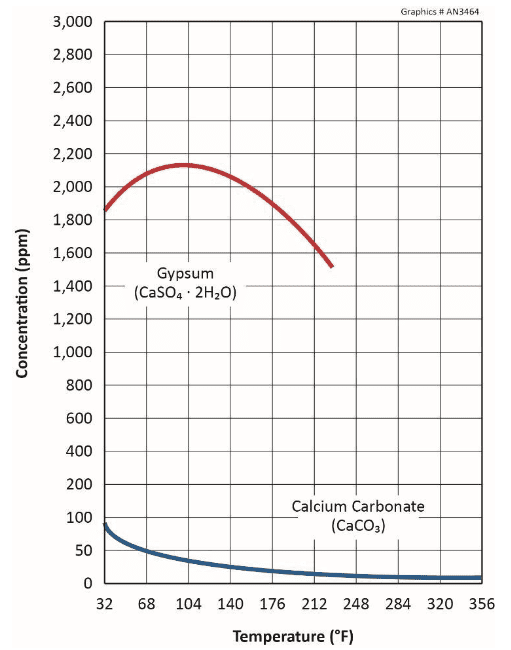

Calcium Sulfate

A sometimes problematic issue is gypsum (CaSO4∙2H2O) scaling, influenced by either elevated sulfate concentrations in the makeup or from acid treatment to remove carbonate.

Calcium sulfate has higher solubility than CaCO3, as shown below.

The figure reveals that gypsum also exhibits reverse solubility, but not until temperatures reach approximately 105o F.

A common general guideline suggests limits of 1,200 ppm calcium (mg/L as CaCO3) and 1,200 ppm sulfate (mg/L as SO4), or some multiple thereof, to prevent scale formation at normal cooling system temperatures in untreated water. Higher limits may be possible with chemical treatment, but these cases should be evaluated on an individual basis.

Calcium Phosphate

As will be outlined in greater detail in the next section, in the 1980s a major shift in chemical treatment of open-recirculating systems occurred with the adoption of inorganic and organic phosphate chemistry for both scale and corrosion control. Suddenly, tricalcium phosphate (Ca3(PO4)2) deposition became a major problem at many facilities.

Besides tricalcium phosphate (Ca3(PO4)2), other calcium phosphate phases can form in cooling water. It is often assumed that the thermodynamically stable hydroxyapatite (Ca5(PO4)3(OH)) is a suitable prototype for scale prediction. It seems that during the precipitation of calcium phosphate, amorphous calcium phosphate (ACP) forms first followed by the nucleation and phase transformation of other compounds.

ACP → Precursor → Stable Phase

Calcium phosphate(s) solubility is strongly dependent on solution pH and temperature. All species show inverse solubility with respect to those two parameters. The scaling tendency of calcium phosphate is also dependent on other influences, including those from other metal ions. All factors must be considered when calculating scaling potential.

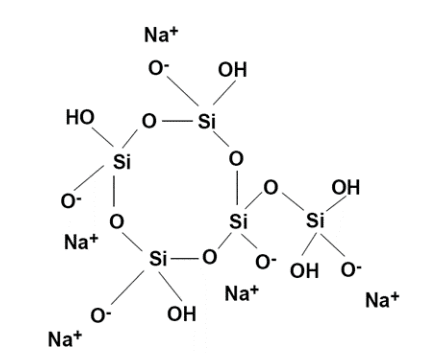

Silica/Silicates

The aqueous chemistry of silica is complex, and any number of precipitates may form depending upon temperature, pH, and other factors. Potential deposits include:

- Amorphous silica in cooler sections of the water system

- Metal silicates in warm/hot locations or at elevated pH

- Silicate minerals such as clay that are suspended in the water

Amorphous silica is simply SiO2. Many surface waters contain low levels (<15 ppm) of silica, however, some groundwaters can have concentrations as high as 75–80 ppm. At ambient temperature, the silica saturation level is around 150 ppm, so as the concentration of silica increases to saturation and above, a polymerization process induces formation of colloidal silica that can attach to system surfaces. This deposition mainly occurs in the coolest locations, such as tower fill.

In the pH range of approximately 2.0–8.3, silica solubility is independent of pH, however, dissolved silica converts to silicate (SiO3–) as pH rises above 8.3. Silicates will precipitate with cations, most notably magnesium and calcium. These compounds exhibit inverse solubility with respect to pH and temperature, and thus will first accumulate in warm locations, i.e., heat exchangers. Silica and silicate scales are very tenacious and difficult to remove. They are also strong insulators that significantly reduce heat transfer.

Some chemical treatment programs may allow operation with dissolved silica concentrations at or perhaps even a bit above 200 ppm. However, thorough knowledge of the water chemistry is necessary to push the envelope of the program. For example, polyvalent ions, such as Zn2+ and Al3+, are surrounded by hydroxyl groups that can catalyze silica polymerization. Among all cations, magnesium has the greatest potential to induce silicate deposition.

Dissolved silica can be analyzed by ultraviolet/visible (UV/VIS) spectrophotometry via the molybdate method. Total silica measurement, including the colloidal form where silica exists as solid particles, requires more advanced techniques, such as inductively coupled plasma (ICP) or atomic absorption (AA) spectroscopy.

Deposition and Corrosion Control

Chemical treatment methods for corrosion and scale control have for years been intertwined, and this section provides a review of the most common programs over the last half century or more, and how past and present methods have been designed to address both issues.

Hearken back to Equation 7-14. In the middle of the last century, a hugely popular treatment program for open-recirculating systems was sulfuric acid feed for scale control (to establish a common pH range of 6.5-7.0), with feed of disodium chromate (Na2Cr2O7) for corrosion control. This latter compound provides chromate ions (CrO42-) that react with carbon steel to form a pseudo-stainless steel layer that can be quite protective.

However, in the 1970s and 1980s dawning recognition of hexavalent chromium (Cr6+) toxicity led to a ban on chromium discharge to the environment, which essentially eliminated chromate treatment for open cooling water systems. The replacement program was quite different, with a key concept being operation at a mildly basic pH (typically around 8.0 or perhaps a bit higher) to assist with corrosion control. The core treatment chemicals became inorganic and organic phosphates. But, as we shall see, this more complicated chemistry (as compared to acid-chromate) increased scaling potential. Figure 7.41 succinctly illustrates the general relationship between corrosion and scaling.

The ability of phosphate to influence pH is shown by the reaction of tri-sodium phosphate (Na3PO4, TSP) in water.

- Na3PO4 + H2O ⇌ NaH2PO4 + NaOH | Eq. 7-23

TSP chemistry has been utilized for decades to adjust pH in high-pressure steam generators (refer to Chapter 4). But inorganic phosphates when applied alone to cooling water can induce heavy Ca3(PO4)2 formation, and indeed when phosphate chemistry emerged as the replacement for acid-chromate, calcium phosphate deposition became very problematic. Accordingly, formulations emerged that included polyphosphates, organic phosphates (aka phosphonates), polymers, and often a small concentration of zinc, all designed for integrated scale and corrosion control.

The optimum residual phosphate concentration depends on factors such as the LSI/RSI/PSI Index of the water, pH, temperature, and the type of other inhibitors in the treatment program. Too much phosphate can result in tri-calcium phosphate scaling on hot surfaces. Phosphate can also precipitate with iron and aluminum.

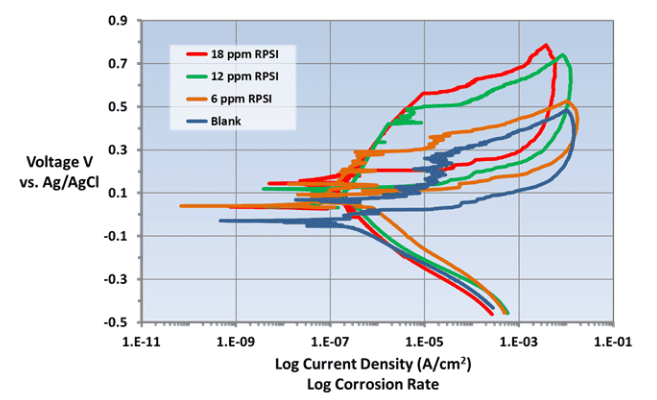

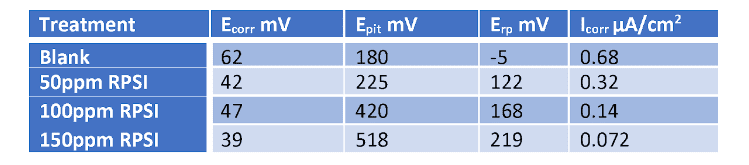

A typical orthophosphate control range is 6–18 ppm.

Polyphosphates

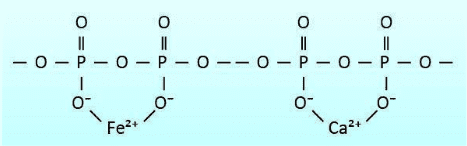

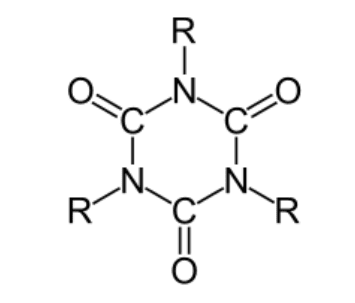

Polyphosphates contain multiple phosphorus atoms connected to each other through oxygen bridges as shown in Figure 7.42. Polyphosphates generally contain from 3–5 units, and have negatively charged oxygen atoms that attract cations including calcium and iron. This attraction effectively sequesters the cations, preventing them from forming deposits.

A “threshold concentration” is necessary to inhibit calcium carbonate scaling when concentrations are at saturation levels. Polyphosphate also combines with manganese. Sodium tripolyphosphate ((Na5P3O10), tetrasodium pyrophosphate (Na4P2O7), and sodium hexametaphosphate ((NaPO3)6) are just some of the polyphosphates. Normally 2 to 5 ppm of polyphosphate is needed in a treatment program. Polyphosphates will hydrolyze and revert to orthophosphate, where various factors such as residence time and temperature influence the rate of reversion.

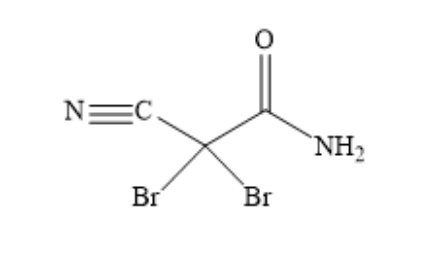

Organophosphates

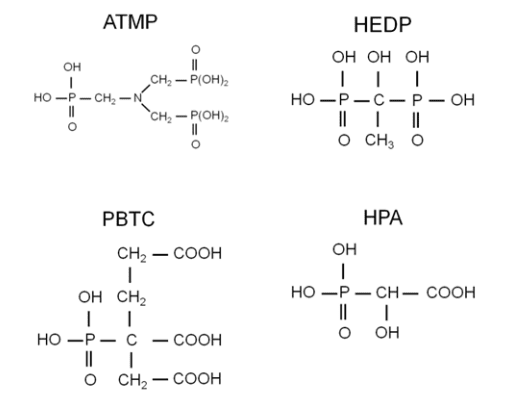

Phosphonates inhibit scale formation by adsorption onto active crystals to retard nucleation and crystal growth rate. Phosphonates also act as sequestrants that form complexes with various cations. Some phosphonates provide corrosion protection, as is briefly described here and in the following section. Four common phosphonates are shown below.

ATMP was the first phosphonate, and was introduced in the early 1970s for calcium carbonate scale control. It served as a replacement for polyphosphates and could extend the saturation indices described earlier to:

- LSI by +1.5

- RSI/PSI by ‒1.5

ATMP exhibited fair to good corrosion inhibitor properties at the alkaline pH ranges of the (then new) phosphate-phosphonate programs. However, ATMP has a low tolerance for oxidizing biocides like chlorine, and it can also form calcium-phosphonate precipitates.

An improvement came with HEDP, which performs similarly to ATMP, but has a higher tolerance to oxidizers. HEDP replaced ATMP in most applications. Further research led to the development of PBTC, which has even higher tolerance for both chlorine and bromine than HEDP. Note the carboxylic acid groups (COOH) on this molecule, which revert to carboxylate (COO–) in alkaline solutions. Carboxylate is a key functional group for many of deposit-control dispersants. PBTC offers good corrosion protection, however, it is more expensive than other products.

HPA is a more recent addition to the organophosphate scale/corrosion inhibitor family, and is particularly effective because it forms a monomolecular layer with calcium on metal surfaces.

Phosphonates are nearly always blended with other deposit control agents and corrosion inhibitors (mainly anodic). The normal phosphonate control range is 2 to 10 ppm (as PO4).

Polymer Developments

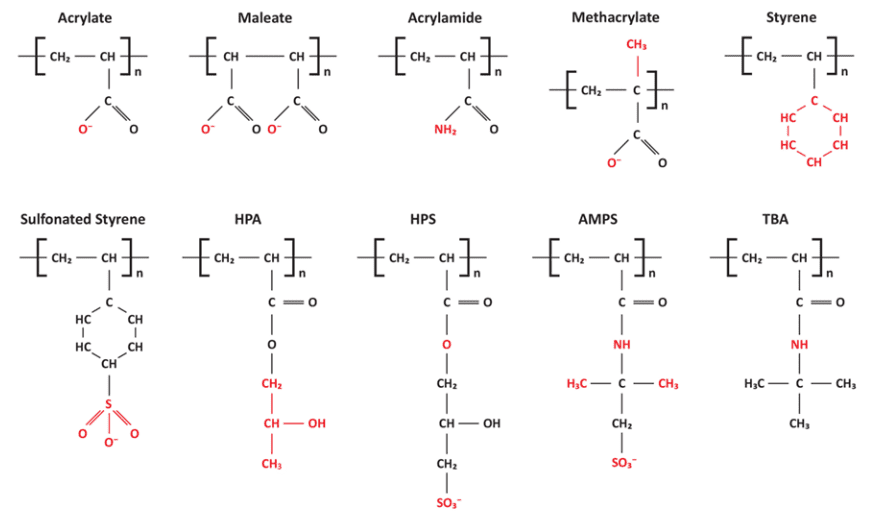

Development of polymers for crystal modification and sequestration have enhanced deposit control chemistry. Figure 7.44 illustrates various functional groups for important water treatment polymers.

Figure 7.44. Functional groups on deposit control polymers. HPA, hydroxypropyl acrylate; HPS, 2-hydroxypropylsulfonate; AMPS: 2-acrylamido-2-methylpropane sulfonic acid; TBA, tert-butyl acrylate.

Along with the functional groups, polymer structure and size have an influence on scale inhibition. Common are molecules of 500–15,000 daltons in size, but in some cases much larger polymers may work well. Some polymers were designed to control calcium carbonate, calcium sulfate, and iron-related deposits, and others to control the calcium phosphates that can emerge from phosphate/phosphonate treatment programs.

Advanced formulations may include co-, ter-, and quad-polymers that have several different functional groups to treat complex waters. The compounds inhibit scale formation through several mechanisms, including sequestration, crystal modification, and crystal dispersion.

Sequestration

As can be observed in Figure 7.44, some of the compounds have the same functional groups, i.e., sulfonate and carboxylate, as those on ion exchange resins for makeup water treatment (see Chapter 3). For both applications, the negatively-charged active sites bind cations, including calcium and magnesium. The key difference is that solid ion exchange resins are contained within a vessel whereas the soluble and mobile deposit-control polymers move throughout the cooling water system. Common generic or trade names for these polymers include:

- Polyacrylate (PAA)

- Polymethacrylate (PMAA)

- Polymaleate (PMA)

- AA/amps Copolymer

Crystal Modification

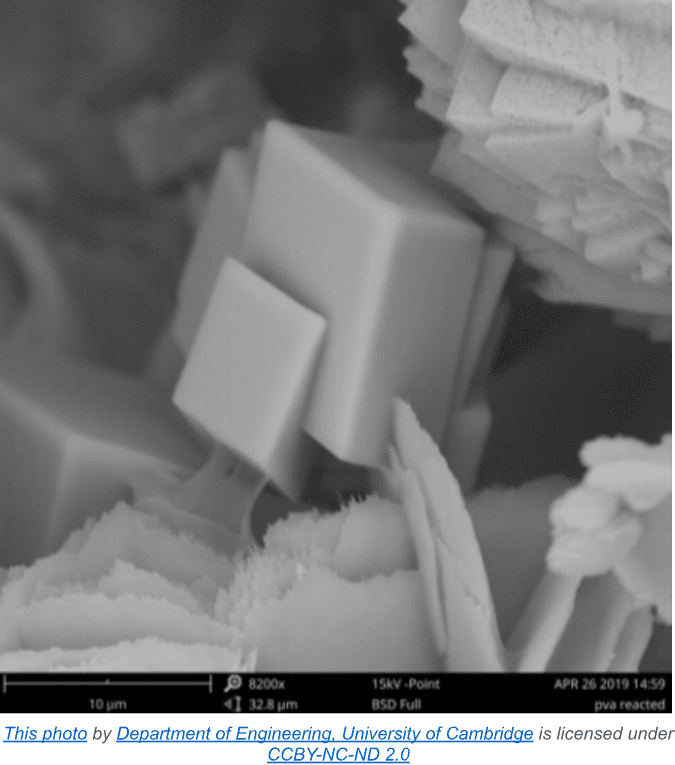

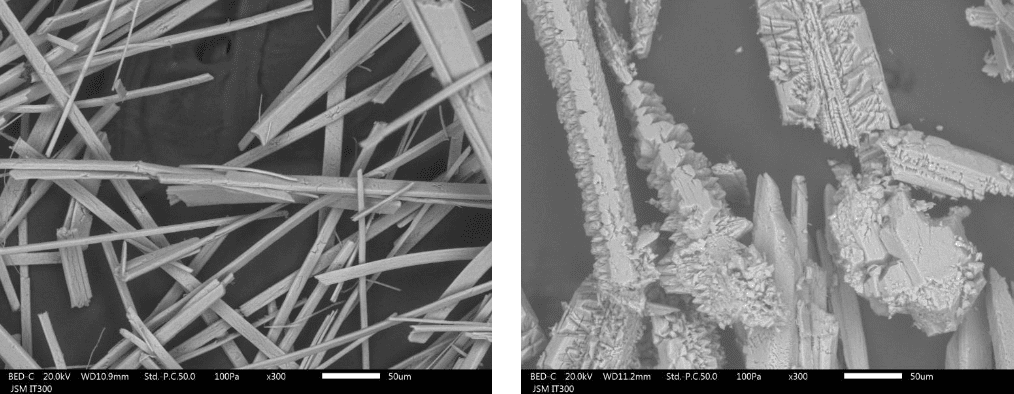

Some polymers modify or distort incipient crystals.

Distorted crystals exhibit none of the needle-like or flat-faced crystals shown in Figure 7.45a, rather the structure is much more fragile, friable, and does not form large crystal grains. PA, PMA, and similar compounds are effective for controlling calcium carbonate.

Calcium phosphate scale control is more difficult, especially on heat transfer surfaces. Scale prevention may require co- or ter-polymers that include sulfonate groups.

Iron presents a challenge to polymer chemistry, as iron binds strongly to carboxylic and sulfonate sites, reducing their effectiveness for calcium sequestration. In many waters, though, the iron concentration is low and does not present significant problems.

Crystal Dispersion

Polymeric dispersants are primarily negatively charged. Suspended particles usually also have an overall negative charge. The polymers enhance the negative charge, causing increased repulsion that keeps particles in suspension. Dispersion can be effective on finely-sized suspended solids such as silt, clay and corrosion products, and possibly some microbiological debris. PAA and PMA are good products for dispersion.

An often-important factor for deposit control is to enhance the ability of the polymers to penetrate deposits. This is especially true for organics, including oils and greases, as these compounds bind deposits together. Biofilm is also an especially strong binding agent. Surfactants can assist in breaking down these materials. Cationic, anionic, and nonionic compounds are all available.

Nonionic surfactants are similar to detergents by having a hydrophilic (water loving) functional group and a lipophilic (oil loving) chain. As the lipophilic end binds with oils, the hydrophilic end attaches to water molecules to remove the oil. Structural modifications to the lipophilic and hydrophobic active sites allow for specialized solvating chemistry.

Anionic surfactants serve for silt and suspended solids dispersion. Anionic surfactants sometimes produce foam, which is usually not a problem with nonionic compounds.

Cationic dispersants are primarily biodispersants or biocides. More details on these chemicals are provided in the microbiological control section of this chapter.

Design Methods to Help Control Deposition

Where silt or macrofouling impacts heat exchanger performance, installation of backwash equipment may be beneficial, if the unit can come off-line periodically for cleaning.

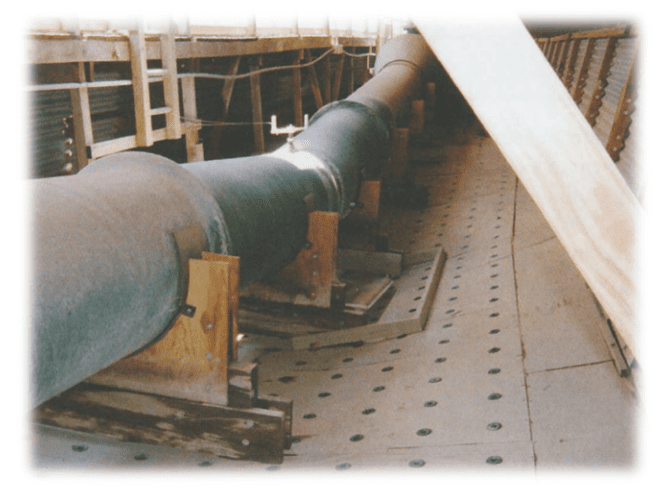

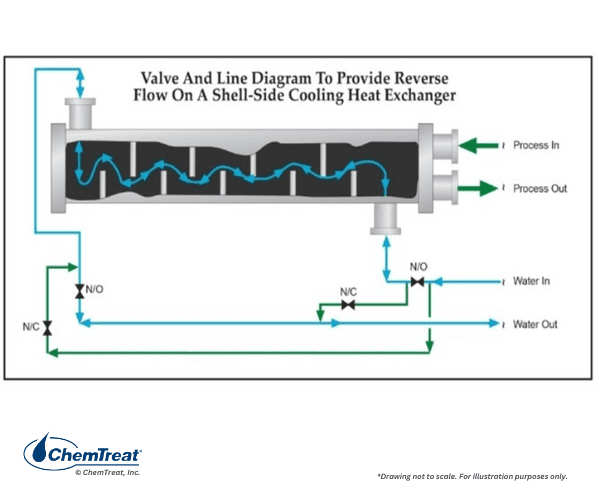

Another modification is to install a manifold below the heat exchanger to air bump the shell side water. This is illustrated in the drawing below.

Corrosion Control

The opening sections of this chapter outlined many of the most important cooling system corrosion issues. We will now examine modern corrosion control techniques.

When open-recirculating cooling water programs were switched from acid-chromate to phosphate-phosphonate-polymer-zinc treatment, much of the chemistry from the latter programs also served for corrosion control.

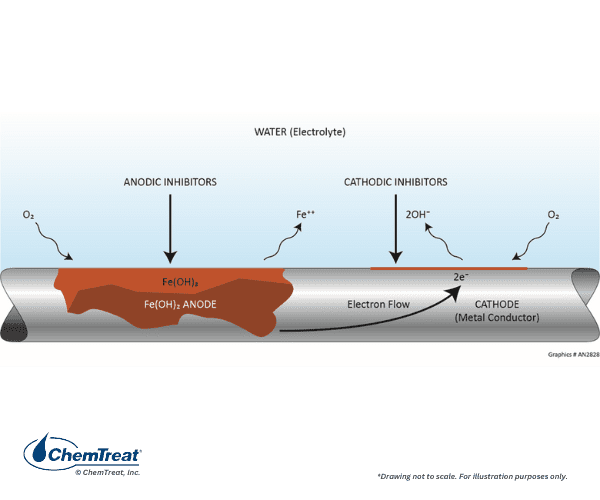

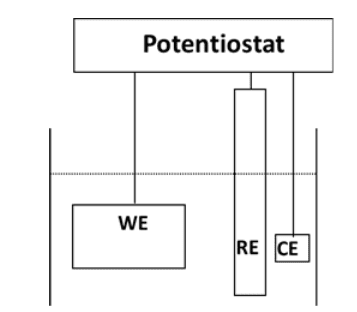

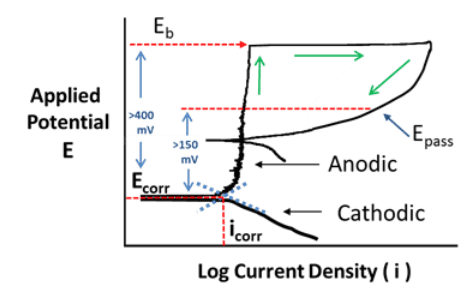

Consider again the basic diagram of the most common corrosion mechanism in cooling water systems, attack of carbon steel by dissolved oxygen. As a reminder, metal oxidation and loss occur at anodes, with electron transfer and reduction of dissolved species at cathodes.

Corrosion inhibitors effectively depolarize (reduce or stop the electrical flow) the corrosion reaction either at the anode or cathode, or both with blended inhibitor programs. In general, cathodic inhibitors precipitate at the locally high pH cathodic site to form a barrier that limits the rate of oxygen reduction. Anodic inhibitors typically promote the formation of a stable metal oxide at the anode surface. This limits metal dissolution. A considerable advancement has come with the development of film-forming products that protect the entire metal surface. Review of this filming technology follows the discussion below of traditional anodic and cathodic inhibition.

Table 7-3. Common Corrosion Inhibitors

| Anodic | Cathodic | Filming |

| Molybdate | Organic phosphates | Azoles (for copper alloys) |

| Nitrite | Ortho-phosphate | Filming Amines |

| Ortho-phosphate | Polyphosphates | Polysilicates |

| Zinc | RPSI* |

Calcium Carbonate – The Natural Corrosion Inhibitor

The earlier section on scale formation suggested that calcium carbonate is the most natural, and often most problematic deposit. However, when calcium and bicarbonate alkalinity concentrations exist in moderation, the presence of both can be beneficial. If the water has at least 50 ppm of calcium hardness and 50 ppm of alkalinity (both as CaCO3), the constituents potentially offer some corrosion protection as a cathodic inhibitor. The key is that at the cathodes shown in Figure 7.47, the production of hydroxyl ions generates a localized region of elevated pH. This can induce formation of a light layer of calcium carbonate that inhibits electron transfer at the cathodes.

Orthophosphate

As has been described, orthophosphate is a primary ingredient in phosphate-phosphonate programs to elevate the pH into a mildly alkaline range and minimize general corrosion. Additionally, orthophosphate reacts with iron (Fe2+) generated at anodes to form an iron-phosphate precipitate that deposits on the anodes and helps to inhibit the electrochemical reactions. Electron spectroscopy analyses have shown that the actual inhibitor layer is a gamma-iron complex with a formula of FeOOH•FePO4. The compound passivates anodes and stifles corrosion reactions. This monomolecular film breaks down over time, and thus requires a continuous phosphate concentration.

Orthophosphate also acts as a cathodic inhibitor under certain conditions. Just as the localized higher pH at the cathode precipitates calcium carbonate and, as we shall see, zinc hydroxide, it can also precipitate calcium phosphate.

Polyphosphate

As noted, polyphosphate sequesters multivalent cations such as calcium and iron to inhibit scaling. These complexes develop a net positive charge and migrate to cathodes to form a barrier deposit. The deposit blocks oxygen from the surface, reducing the corrosion current.

Zinc

Zinc has been a standard additive to phosphate-phosphonate programs, with a common recommended concentration of 0.5-1.0 ppm. Zinc reacts with the hydroxyl ions produced at cathodes to form a zinc hydroxide (Zn(OH)2) precipitate that depolarizes cathodic reactions. Zinc can be effective against pitting corrosion. It has been a common practice to combine zinc with an anodic corrosion inhibitor such as orthophosphate for complete corrosion protection.

Many zinc compounds are highly insoluble, including zinc phosphate, and, if sulfide contaminants are present, zinc sulfide.

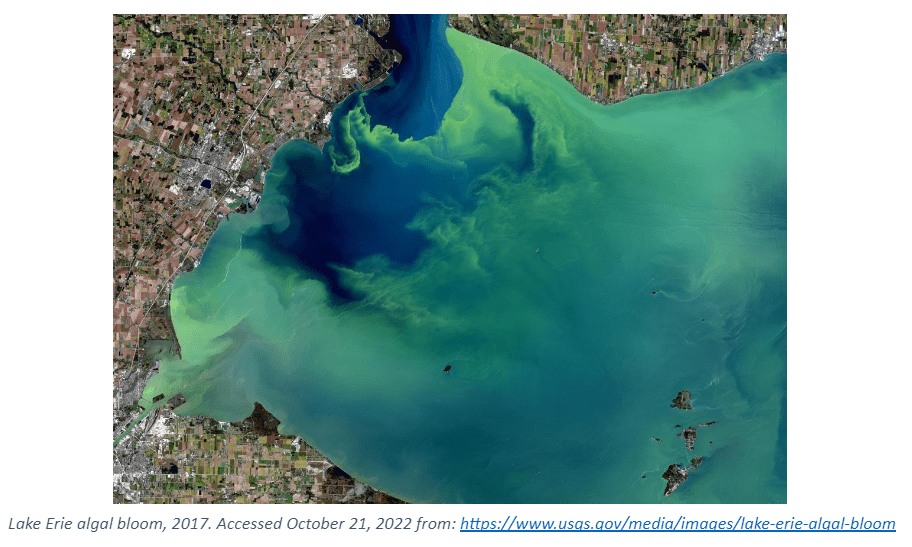

Environmental Concerns of Phosphate-Phosphonate-Zinc Chemistry

Of considerable and growing concern is phosphorus discharge to natural bodies of water, and the effects such discharge has on proliferation of toxic algae blooms.

At many locations now, phosphorus discharge is limited if not entirely banned. Also being restricted is metals discharge, including zinc and copper. These restrictions are a major factor in movement away from phosphorus-based programs to alternative film-forming programs.

REDUCING PHOSPHATE USAGE IN AN AMMONIA PLANT WITH FLEXPRO® COOLING TECHNOLOGY

Filming Chemistry

As the preceding sections have suggested, the key function of corrosion inhibitors is to protect metal surfaces. The former acid-chromate programs were excellent in this regard in that over time the chromate would react with the entire metal surface and establish continuity, as long as sufficient residual concentration was maintained in the cooling water. But the change to phosphate-phosphonate programs altered this methodology. Corrosion inhibition is in large measure accomplished by precipitation of solid products at cathodes and anodes. These deposits can be washed away, allowing localized corrosion. Conversely, overfeed may induce heavy precipitation of calcium phosphate and sometimes calcium phosphonates.

Accordingly, per a multi-year research effort discussed in reference 3, ChemTreat developed a suite of non-phosphate/non-zinc, non-fouling corrosion control programs, which “interact directly with metal surfaces to form a reactive polyhydroxy starch inhibitor (RPSI) complex that is independent of calcium, pH, or other water chemistry constituents.” The chemistry establishes a direct protective layer on metal surfaces, unlike the phosphate/phosphonate programs that rely on deposition of reaction products to form protective barriers, which, as has been noted, can be difficult to control.

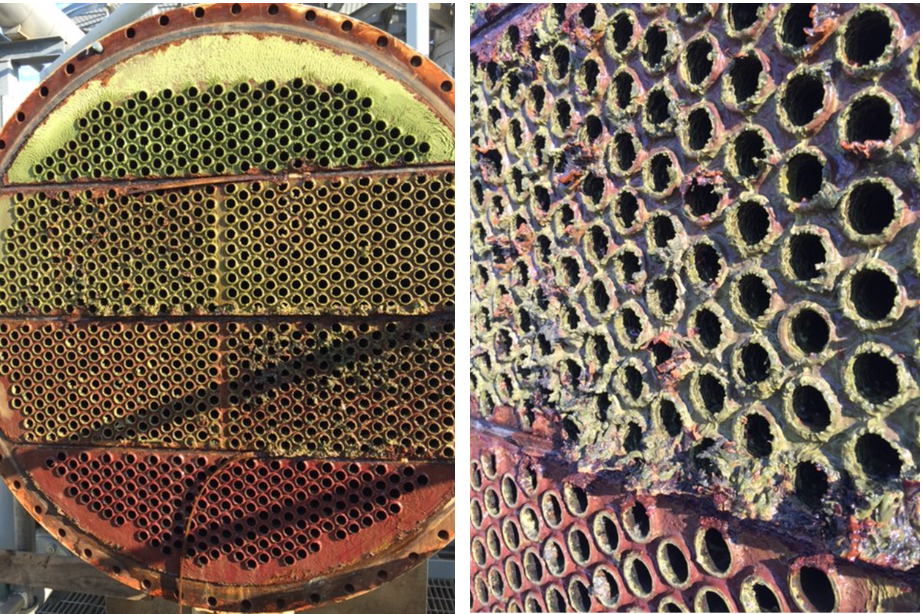

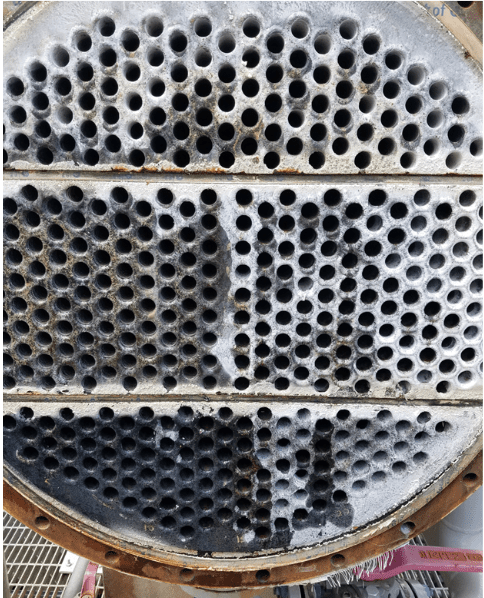

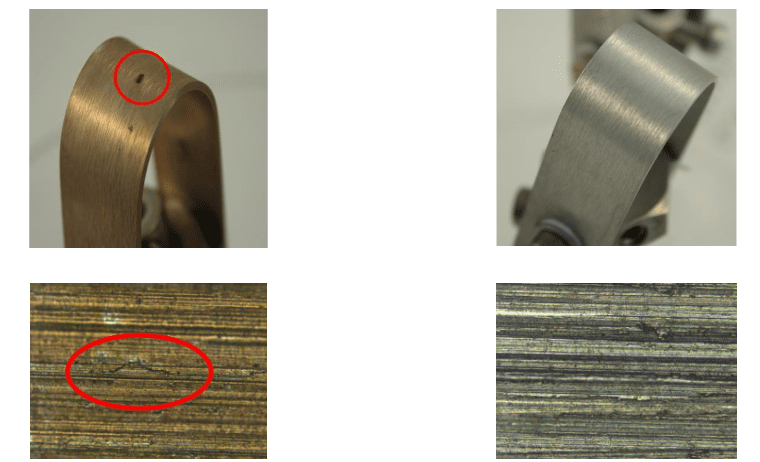

A classic example of the need for improved corrosion protection methods is shown in the following illustration of a two-pass tube-and-shell heat exchanger, whose cooling water at the time was treated with a traditional phosphate-phosphonate program.

At the inlet end of the heat exchanger (the lower tubes of this unit), corrosion was problematic. At the warmer outlet side (the top half), deposition and scale formation were troublesome. Thus, the original program was not effective at mitigating corrosion or deposition depending on location. A switch to RPSI chemistry eliminated both issues.

Closed Cooling Water (CCW) Corrosion Control

Primary cooling at many industries is a critical aspect of operation, and upsets can cost much money in lost efficiency and production. But often overlooked are auxiliary closed cooling water systems, which also serve vital processes. Failure of a closed system has the potential to shut down a portion, if not all, of the plant.

Tight chemistry control is an aspect that makes closed cooling effective for many applications. But, neglect of water treatment and monitoring can lead to corrosion and fouling.

The term “closed” cooling water system is somewhat of a misnomer, as virtually all systems experience leaks or small losses that require makeup. (If serious corrosion has occurred, these losses may be significant.) Systems are often designed with a head tank for makeup and to handle changes in demand. Some head tanks are open to the atmosphere, allowing oxygen to enter the cooling water and influence the corrosion potential.

While it may be possible to utilize water with varying qualities in CCW systems, a common choice, and the main focus of this discussion, is condensate or demineralized water that is specially treated. Selection of condensate over less pure water minimizes the possibility of difficulties from scale-forming hardness compounds or corrosive agents such as chloride and sulfate. For systems that could potentially freeze during cold weather, a glycol solution may be required. This chemistry can obviously influence monitoring and dosage requirements.

Typical piping material for CCW systems is carbon steel, with stainless steel or perhaps copper alloys being a common choice for heat exchanger tubes, or plates in a plate-and-frame exchanger. Other metals may include aluminum or those metals contained in soldered fittings within heat exchanger cooling coils. When planning a treatment program, it is important to know the complete system metallurgy.

Two common cooling water corrosion inhibitors are nitrite and molybdate, as outlined below.

Nitrite

Nitrite (NO2‒), usually fed as sodium nitrite (NaNO2), is an anodic inhibitor by virtue of the chemical reaction with iron hydroxide at anodes. Sodium nitrite is an inexpensive and safe chemical to handle. As shown in the following reactions, nitrite promotes the formation of a passive iron oxide layer on the metal surface.

- 9Fe(OH)2 + NO2 → 3Fe3O4 + NH4 + 2OH + 6H2O | Eq. 7-24

- 9Fe(OH)2 + NO2 → 3(Fe2O3) + NH4 + 2OH + 3H2O | Eq. 7-25

Common is the addition of an alkalinity builder/buffering agent to maintain pH within a mildly alkaline range.

Anodic inhibitors such as nitrite are also known as “dangerous” inhibitors, because if residuals fall below threshold limits, a small number of anodes will develop in a large cathodic environment. Rapid pitting may occur. Accordingly, a common recommended nitrite residual range is 500-1,000 ppm to inhibit general corrosion and pitting. However, when used with other inhibitors such as molybdate, lower nitrite residuals may be satisfactory. A concern with nitrite is that it is an excellent nutrient for bacteria. Nitrobactera agilis can grow rapidly by converting nitrite to nitrate. A classic example comes from an automobile assembly plant, where nitrifying bacteria plugged the small, serpentine cooling water tubes in automatic welders. Oxidizing biocides are not suitable for microbiological control, as the oxidizers convert nitrite to nitrate. A non-oxidizing biocide (see discussion later in this chapter) may provide effective control.

Molybdate

Sodium molybdate (Na2MoO4) was first used as a corrosion inhibitor in 1939 for automotive cooling systems. It appears that molybdate acts similarly to chromate and adsorbs onto the iron oxide matrix at anodes.

- Fe2+ + MoO42- → FeMoO4↓ | Eq. 7-26

This layer then may further evolve into what is known as a gamma iron complex. Research shows that molybdate acts as a pitting inhibitor per its ability to accumulate within the acidic part of a pit and block the corrosion process. A common control range for molybdate is roughly 1/3 of nitrite. Although molybdate is an oxyanion, it requires some residual oxygen to be effective. Enough dissolved oxygen may enter through the cooling water makeup or head tank to provide the needed amount.

Molybdate is an expensive chemical, and costs may be prohibitive in some applications.

Copper Alloy Corrosion Inhibition

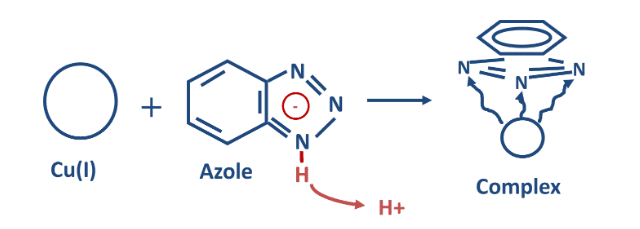

Copper is a superb metal for heat transfer, and thus copper alloys have been selected for many heat exchanger tubes. While copper is a more noble metal than iron, significant corrosion is possible in certain environments. As previously noted, the combination of dissolved oxygen and ammonia can be particularly corrosive. The most popular corrosion control methods for years have utilized azoles, in another example of film-forming chemistry. Figure 7.52 illustrates the general effect.

Azoles bond with copper atoms on the metal surface via an active nitrogen group. The plate-like organic ring then forms a barrier to protect the metal from the bulk fluid. The most common azoles are listed below.

Benzotriazole

1,2,3-Benzotriazole (BZT – C6H5N3) is the compound shown in Figure 7.52. It is the most fundamental azole, but offers good corrosion inhibition in circulating cooling water systems.

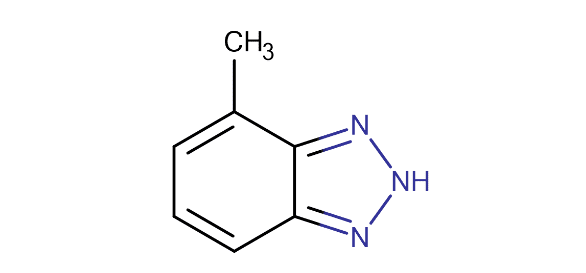

Tolyltriazole

Tolyltriazole (TTA – C7H7N₃) is similar to BZT but with a methyl group added to the organic ring.

The methyl group helps orient the molecule to establish a more uniform barrier film.

Another of the early azoles is 2-mercaptobenzothiazole (MBT), which has two sulfur groups in the nitrogen ring. One of the sulfur atoms also bonds with copper to form a thick passive film.

A difficulty with these original compounds is attack by oxidizing biocides, which, of course, are necessary for microbiological control. Water treatment companies have developed halogen resistant azoles that contain additional side groups to resist oxidizer attack.

Recommended azole concentrations are usually maintained within a range of 1–10 ppm, and often 2–5 ppm.

In addition to bonding with the metal surface, azoles also form complexes with free copper ions in solution. So, dissolved copper contributes to the azole “demand,” which must be satisfied before surface filming can occur. However, if the azole is applied properly, any free copper should rapidly disappear and not normally be present thereafter. Azoles remain an important part of many FlexPro programs.

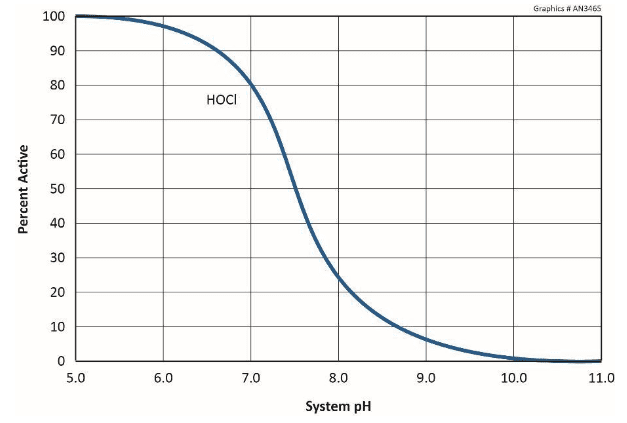

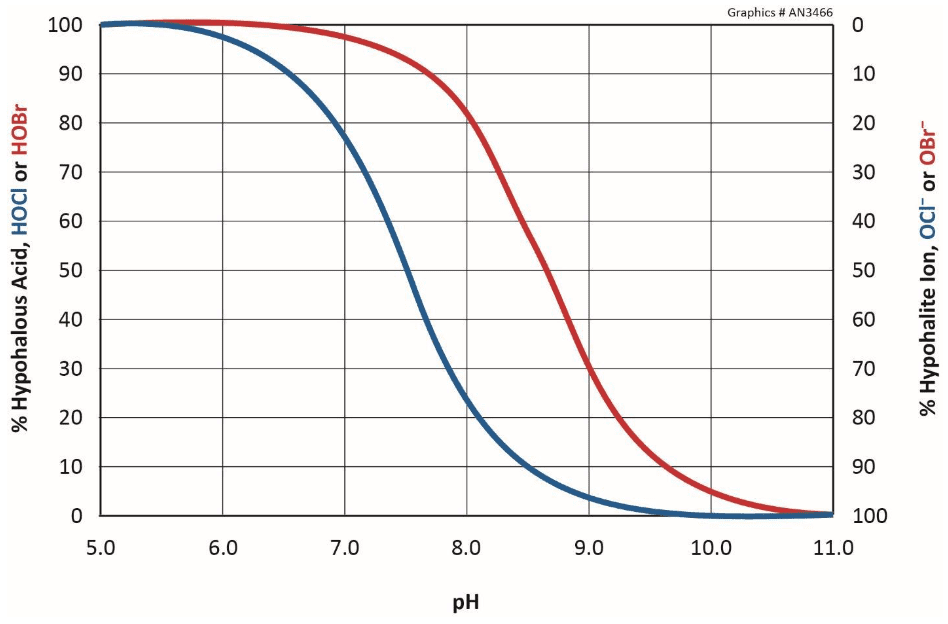

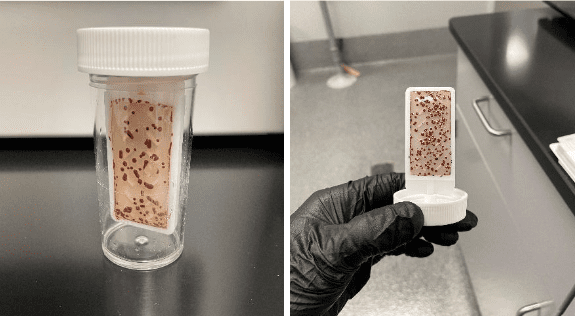

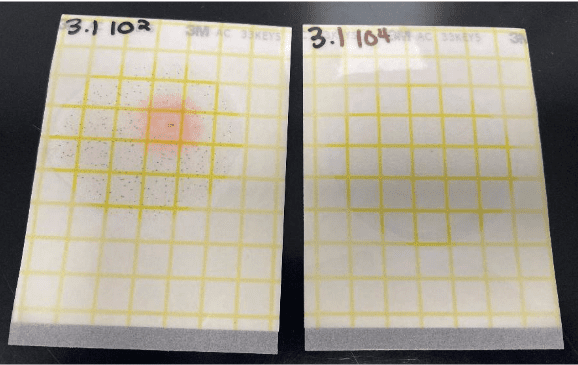

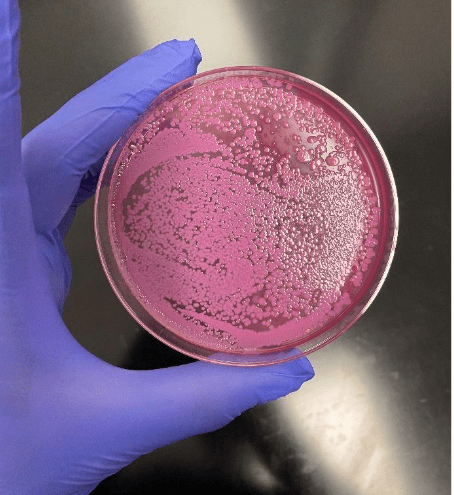

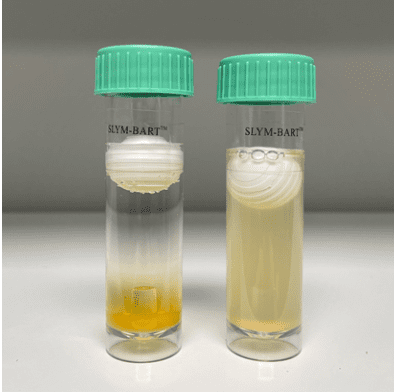

Amines