-

USA - English

- Locations

- SDS Access

- CTVista®+ Login

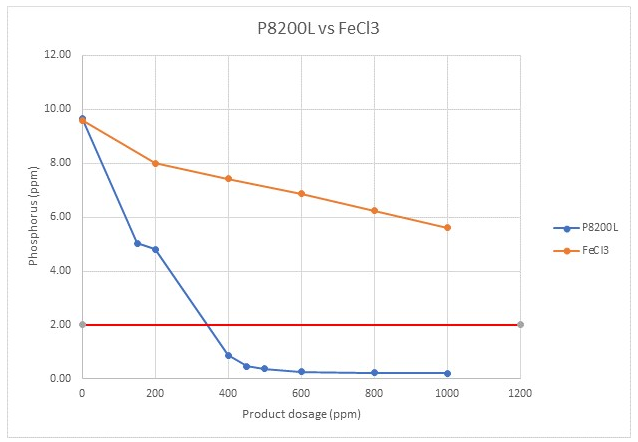

Water consumption is a significant cost factor in the beverage industry. Large quantities of wastewater are generated because of high water consumption. One large Mexico beverage bottling plant was faced with the challenge of decreasing the phosphorus levels discharged from their wastewater processing plant to less than 2.0 ppm as 'P'. Operational flow at the plant averaged 251,061 gallons per day, and the treatment included an aerobic reactor, MBBR, and clarifier. Previous customer attempts to control phosphorus levels using traditional inorganic salts were unsuccessful.

ChemTreat used a combination of historical effluent data, current water analyses, and a thorough plant survey to develop a treatment plan using our P8200 product family to achieve phosphorus levels less than 2.0 ppm as 'P'. The plan took process optimization, feed points, contact time, and flocculant selection into account. ChemTreat’s technology was put to test with a full-scale plant trial.

During the trial, ChemTreat’s treatment program successfully controlled phosphorus levels below 2.0 ppm as 'P', whereas before treatment, phosphorus levels measured at the outlet of the biological reactor averaged 8.8 ppm as 'P'.

After treatment, the effluent phosphorus levels averaged 0.72 ppm. Another benefit to ChemTreat’s P8200 series treatment was a 30% decrease in sludge volume compared to traditional treatment. Based on these results, the bottling plant incorporated the ChemTreat technology into their wastewater treatment plan.

Results are examples only. They are not guaranteed. Actual results may vary.