-

USA - English

- Locations

- SDS Access

- CTVista®+ Login

A Midwestern ethanol plant was applying an older generation filming amine in combination with a neutralizing amine in their boiler and condensate systems. This program did not maintain iron levels to the plant’s specifications, so they asked ChemTreat to find a new solution.

ChemTreat recommended applying BL8421F, a treatment that combines next-generation film-forming amine (FFA) with a specialized polymer, neutralizing amines, and a fluorescent dye.

BL8421F offers extensive benefits compared to its predecessor:

The plant decided to run a trial application of BL8421F, focusing on minimizing iron in the condensate and feedwater while cleaning up existing deposits in the system.

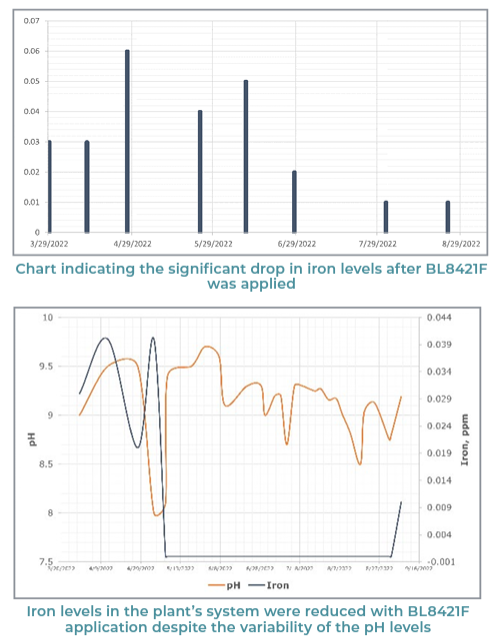

After a month of feeding BL8421F, the condensate iron became undetectable even though the pH fluctuated between 8.0 and 9.7.

One month later, boiler feedwater iron declined to <0.02 ppm and was trending at <0.01 ppm several months later when the system was opened up for an inspection during an outage.

Two months into the trial, the steam drum had a coarse black iron oxide layer, indicating that the metal was not fully passivated and actively corroding.

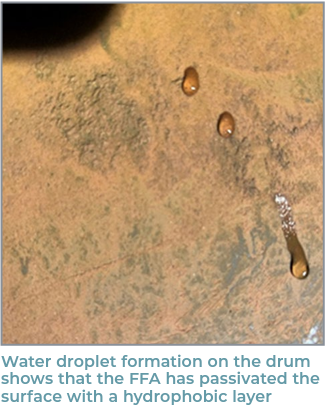

Several months later, the iron was transformed into a fine powder tightly adhering to the drum, indicating that corrosion had been arrested and the drum surface passivated.

The mud drum and the deaerator exhibited similar results during the inspection.

Five months into the trial, the ethanol facility had a passivated boiler with reduced deposition. pH and fluorescence measurements confirmed the accuracy of the feed rate under variable conditions.

Pleased with the results of the trial, the facility plans to continue using the FFA program in their water treatment process.

Results are examples only. They are not guaranteed. Actual results may vary.