-

USA - English

- Locations

- SDS Access

- CTVista®+ Login

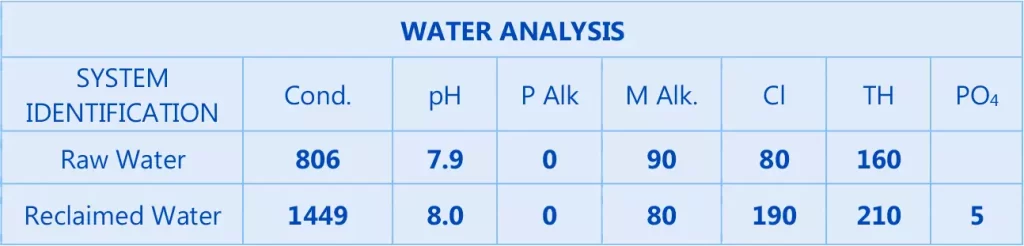

A Western U.S. data technology company uses multiple makeup water sources for redundancy and environmental sustainability. ChemTreat faced two main challenges with this type of variable makeup to a cooling tower:

Maximize reclaim water use and minimize chemical usage without compromising heat exchange surfaces to help prevent downtime and minimize the plant power usage effectiveness (PUE). Other specific goals included:

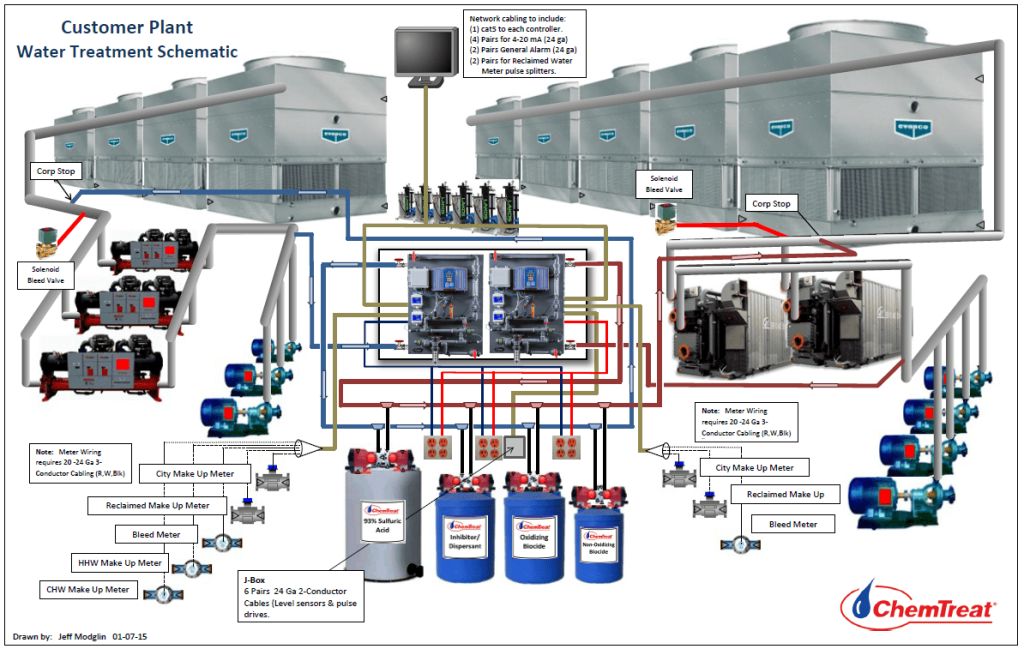

ChemTreat used programmed non-proprietary water treatment equipment. Specific water treatment chemistries were selected to provide protection during variations in water treatment makeup while maintaining water savings. Treatment was set up in the following manner:

Programming the controller with input from meters allowed the system to automatically maintain stability.

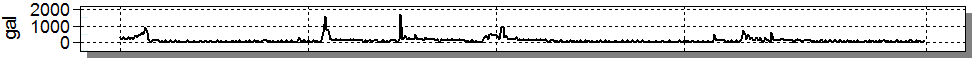

Cooling Towers, City Makeup

Min: 100

Max: 8,200

Average: 136.93

Total: 66,000

Cooling Towers, Reclaimed Makeup

Min: 100

Max: 1,700

Average: 112.66

Total: 54,300

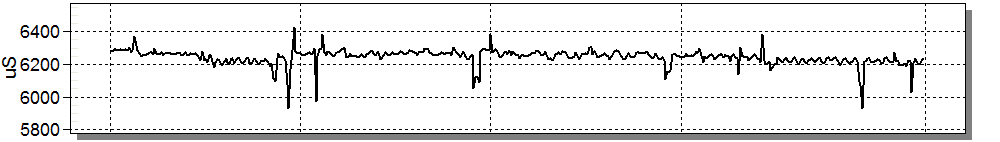

Cooling Towers, Average Conductivity

Min: 5,928.935

Max: 6,426.607

Average: 6,244.340

Results are examples only. They are not guaranteed. Actual results may vary.