-

USA - English

- Locations

- SDS Access

- CTVista®+ Login

A coal-fired power plant in the Southeast US was struggling with declining condenser performance. The back pressure was not aligning with expectations based on the operational and environmental conditions. A tornado had recently hit the cooling tower, and it was suspected that cooling tower performance was the primary contributor to the issue.

Pinpointing the source of the problem is critical when troubleshooting, analyzing, and solving condenser issues. The findings also needed to be conveyed in a way accessible to the non-technical personnel in charge of authorizing any repairs or capital expenditures.

To gather and analyze the operational data, the plant employed ChemTreat’s Condenser Performance Monitoring technology, part of the patented CTVista®+ platform. Designed to collect and analyze plant historian data, the program performs the necessary calculations and provides troubleshooting based on machine-learning techniques designed to identify potential problem areas.

Gathering and digesting data is a key component of monitoring condenser performance. Some plant historians track 25,000 variables or more, but not all of them are necessary to model condenser issues. Our program captures only the variables essential to the troubleshooting process. At this site, additional critical variables were incorporated because the suspected root cause was cooling tower performance.

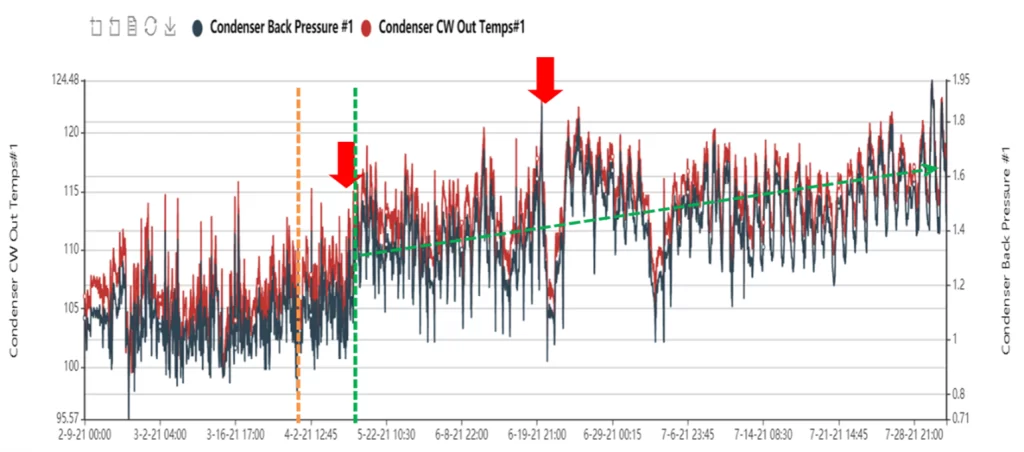

The graph below, generated within the Condenser Performance Monitoring Program, shows the shifts in operating back pressure and the cooling water outlet temperature in a steady upward trend.

After gathering and analyzing the plant historian data, it became evident that macrofouling had occurred. The cooling tower had lost some of its fill as a result of the tornado damage, which ended up in the condenser, causing reduced flow through the condenser tubes.

The second phase of the troubleshooting process involved determining the net effect from the cooling tower performance degradation. This was a necessary step for calculating the cost of efficiency loss to justify any repairs. Using the Condenser Performance Monitoring Program and an approximate cost of $40 per megawatt, the ChemTreat team was able to calculate an estimated loss of $970,000 in production costs for the three months the plant was experiencing problems.

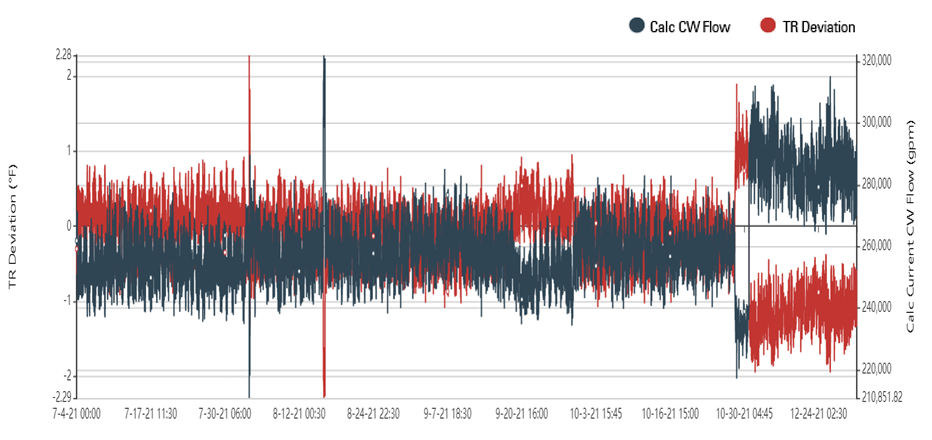

Based on this analysis, the plant shut down and opened up the equipment to clear out the tower fill and debris in the cooling tower basin, circulating water pump screens, and condenser inlet. This cleaning resulted in a circulating water flow improvement of over 11% and a terminal temperature difference (TTD) improvement of approximately 1.5°F. This equates to a heat rate improvement of approximately 50 Btu/kWhr. The graph below shows the improvement in performance after the debris was cleared out of the system.

The Condenser Performance Monitoring Program helped plant personnel determine that the recovery from the tornado strike was not complete until the debris affecting the pumps, screens, and condenser inlet was removed. Once completed, system performance was restored.

Results are examples only. They are not guaranteed. Actual results may vary.