-

USA - English

- Locations

- SDS Access

- CTVista®+ Login

Maintaining building water systems is essential to reduce the risk of Legionella growth and transmission.

ANSI/ASHRAE Standard 188, Legionellosis: Risk Management for Building Water Systems provides guidance for the risk management of Legionella and water systems. This standard provides a framework to develop a water management plan to minimize risk associated with illness.

The Cooling Technology Institute (CTI) has published a new document: Legionellosis Guideline GDL-159, Practices to Reduce the Risk of Legionellosis from Evaporative Heat Rejection Equipment Systems.

ChemTreat works with our customers to develop Legionella water management plans in accordance with the risk management requirements set forth by ANSI/ASHRAE Standard 188.

For guidance around maintaining buildings during prolonged shutdowns, click here.

Legionella bacteria is just one challenge companies face when managing their cooling programs. ChemTreat field representatives are experts in industrial cooling, with extensive experience in a variety of applications.

We offer cooling tower treatment programs such as:

To learn more about our cooling water treatment offerings, click here.

The Centers for Medicare and Medicaid Services (CMS) require healthcare facilities to reduce Legionella risk in their water systems to prevent cases and outbreaks of Legionnaires’ Disease.

Medicare and Medicare/Medicaid-certified healthcare facilities are expected to have water management policies and procedures to reduce the risk of Legionella growth and transmission.

CMS recognizes the ANSI/ASHRAE Standard 188 and its partner, the CDC Toolkit, as resources for developing water management programs.

ChemTreat partners benefit from our expertise in many areas of Legionella risk management:

In the healthcare industry, managing waterborne pathogens in potable water systems is an integral part of a successful water treatment program.

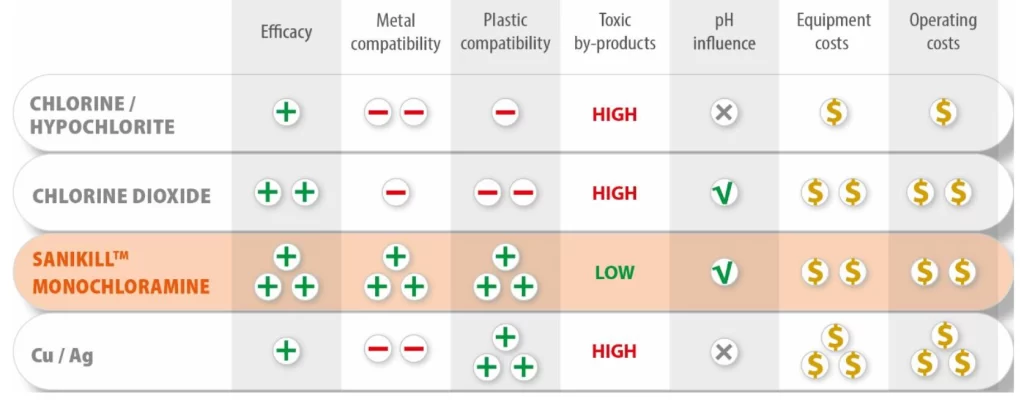

ChemTreat has partnered with Sanipur to offer SANIKILL®, a monochloramine-based supplemental disinfection technology for potable water systems. This patented technology offers many benefits over chlorine-based oxidizers and other industry-standard disinfection technologies.

With a lower oxidation potential than chlorine-based alternatives, SANIKILL can be used as a disinfectant for long periods without damaging potable water piping systems.

This technology provides automated on-site monochloramine production and treatment that can be monitored remotely and reduce handling requirements.