The Problem

A meat production facility in the Midwest was struggling to control high total suspended solids (TSS) levels in their effluent, which was causing increased wastewater discharge fines.

For food & beverage facilities, wastewater treatment is one of the most difficult processes to control. This can often be attributed to the frequency of process changes to meet production and market demands.

After struggling to meet effluent TSS targets in their dissolved air flotation (DAF) system, the plant asked ChemTreat to perform an audit of their wastewater treatment facility to troubleshoot their systems.

The Solution

The ChemTreat team analyzed the historical data captured within CTVista®+ to identify areas of improvement prior to performing a site visit. During the visit, ChemTreat worked with plant engineering and operations staff to identify other areas of improvement, including:

- Equipment settings

- Application and optimization of PUREFloc™ coagulant chemistry

- General operational guidelines

ChemTreat also helped optimize the facility’s installed RTC DAF automation technology with PUREFloc products to improve effluent TSS results.

The Results

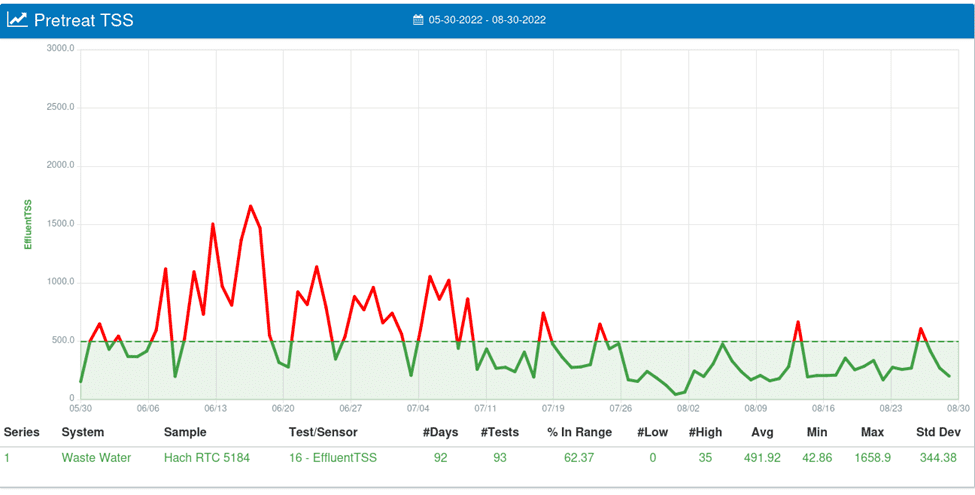

Prior to ChemTreat’s site visit, effluent TSS values were within the target range just 53% of the time over the previous six months. Since implementing ChemTreat’s recommendations, the plant has been able to keep effluent TSS values within target 94% of the time.

Thanks to ChemTreat’s optimizations, the facility was able to reduce monthly surcharge fines by approximately $11,000. Optimizing the RTC DAF system and chemical application for more robust automation helped reduce chemical dosing by 20–30%. According to plant management, enhanced control of the wastewater system has allowed this facility to allocate staff to other areas of the plant while maintaining a high level of environmental stewardship and compliance.

CTVista+ graph showing the decrease in effluent TSS. ChemTreat conducted the site visit on July 25–26, after which the TSS levels have been consistently in range 94% of the time.

Results are examples only. They are not guaranteed. Actual results may vary.