The Problem

A microchip manufacturer was experiencing significant issues in their cooling system closed loops. Their previous water treatment program, which used a nitrite-based corrosion inhibitor and nonoxidizing biocides, did not effectively mitigate biofouling and underdeposit corrosion, resulting in high iron concentrations; increased turbidity and suspended solids in the water; and heat transfer loss on heat exchanger surfaces. Instances of biofilm sloughing off the piping reduced water flow, making it difficult to control temperatures.

These issues severely impacted the quality of the microchips being manufactured. Many chips had to be scrapped, resulting in significant waste and cost increases.

The Solution

Nitrite-based corrosion inhibitors may promote microbial growth if an effective microbiological control program is not in place. ChemTreat applied several proprietary treatment products to the chilled water loop and implemented bleed-and-feed to reduce the residual concentration of nitrite.

Once the residual concentration of nitrite was reduced, ChemTreat’s chlorine dioxide product CL3000 was fed to inhibit biofouling.

A separate chemistry was applied to the heat recovery and heating loops to reduce corrosion and improve heat transfer on heat exchanger surfaces in those systems.

Sidestream filtration was introduced and additionally enhanced via ChemTreat products to augment the chemical treatment program.

The Results

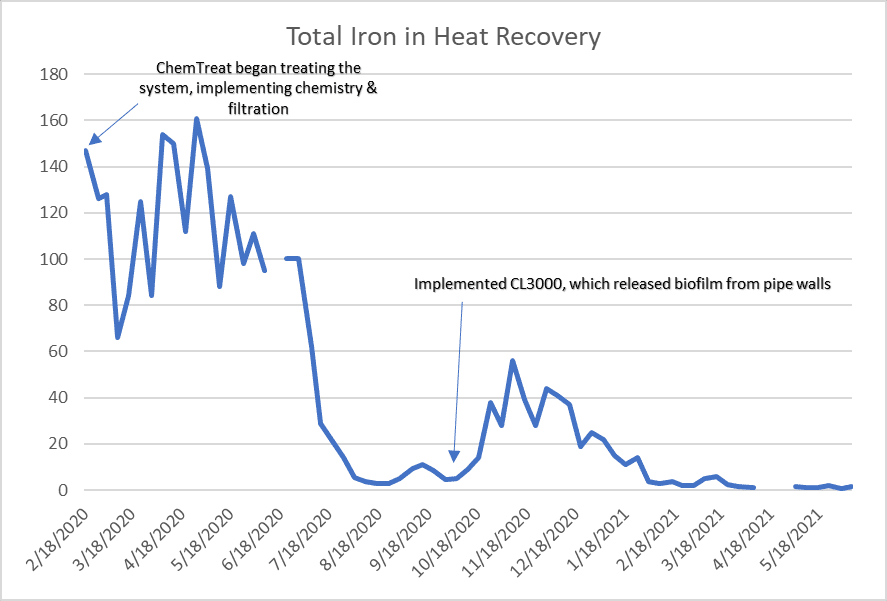

Within a few months of ChemTreat taking over the closed loop treatment, the facility saw the iron concentration go down from 150 ppm to <2 ppm as iron in the chilled water loop. Turbidity significantly improved as well.

Graph illustrating the reduction of iron in the system after ChemTreat’s treatment program was implemented, with a slight spike after CL3000 treatment released biofilm from the pipe walls

Facility personnel have been pleased with the results and their positive impact on water quality and consistency. Based on the program’s success, the customer has asked ChemTreat to apply the treatment on other systems at their facility.

Download the Case StudyResults are examples only. They are not guaranteed. Actual results may vary.