The Problem

A large U.S. oil refinery wanted to reduce coagulant costs in their wastewater processing units while improving their environmental impact. This refinery has five different coagulant applications as part of its wastewater processing.

The Solution

ChemTreat recommended its PUREFloc product line as a replacement for the traditional polyDADMAC/PAC blend being used at the site. PUREFloc coagulants are naturally occurring polymers that remove oil from wastewater more effectively than synthetic organic alternatives while reducing polyaluminum chloride usage.

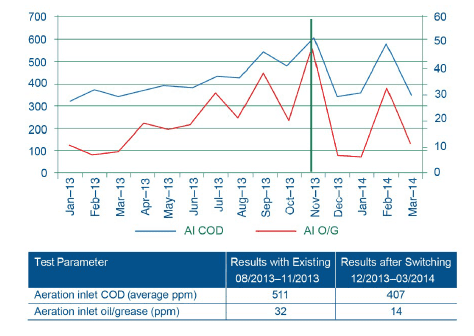

Aeration Inlet COD and Oil/Grease Before and After PUREFloc Application

The Results

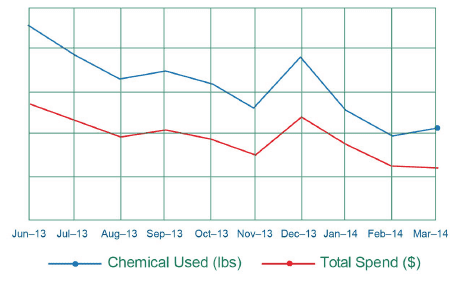

Applying PUREFloc successfully reduced aeration inlet chemical oxygen demand (COD) by 20%, aeration inlet oil/grease by 44%, and quarterly chemical spend by 18%. After the success of the trial, the facility began using this technology full-time.

Reduction in Chemical Usage and Total Spend After PUREFloc Application

Download the Case StudyResults are examples only. They are not guaranteed. Actual results may vary.