The Problem

An industrial manufacturer in the Southern US uses clarified river water for their process and utilities systems. This clarified service water is distributed through the facility in mild steel, stainless steel, and copper pipes.

In 2018, ChemTreat replaced a zinc/phosphate dispersant program to improve mild steel corrosion rates and help the facility meet its environmental goals. The replacement program saved over $100,000 in annual treatment costs.

In 2020, the facility approached ChemTreat regarding their decades-long issue with a high copper failure rate in HVAC units using service water for cooling. The issue cost the plant approximately $400,000–$450,000 per year in equipment replacement, efficiency loss, and cleaning costs.

The Solution

The local ChemTreat engineering service team partnered with ChemTreat R&D, analytical lab, technical staff, and product management to troubleshoot the copper corrosion issue and design a custom treatment program suited to the facility’s needs.

The following plan was implemented over an 18-month period:

- Copper corrosion coupons installed in the service water to measure baseline copper corrosion rates without treatment.

- ChemTreat’s lab analyzed the failed copper taken from several HVAC units to investigate the corrosion process.

- ChemTreat’s R&D conducted an extensive laboratory evaluation, testing different corrosion inhibitors at different operating conditions. A specific chlorine-resistant copper corrosion inhibitor was selected based on its superior cost-effective performance over other treatment options.

- A continuous copper corrosion probe was installed to measure the system corrosion rate and correlate copper corrosion to pH, conductivity, ORP, and temperature. The water temperature was found to the dominant factor influencing service water copper corrosion.

- A pilot site was set up to confirm the efficacy of the new treatment. Over a six-month period, the copper corrosion inhibitor was tested under all service water conditions to confirm dosage rates and the resulting copper corrosion levels.

The Results

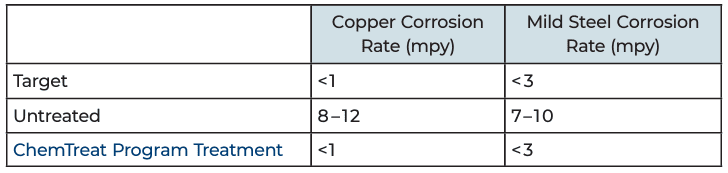

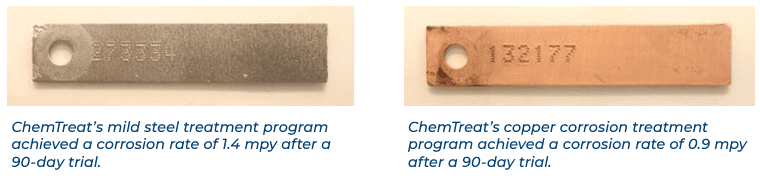

After the application of the copper corrosion inhibitor, service water copper corrosion control is the best ever documented at this customer site.

Since applying ChemTreat’s treatment product, the facility has maintained copper corrosion rates at the desired range, saving $150,000 in annual operational costs.

Service water corrosion now meets the defined key performance indicators. Savings associated with both ChemTreat’s mild steel and copper corrosion treatment programs resulted in a $250,000 annual reduction in total cost of operation for the plant.

Results are examples only. They are not guaranteed. Actual results may vary.