New Wastewater Treatment Processes for Plant Makeup Changes

By choice or mandate, owners and design engineers for many new power and industrial plants are selecting alternatives to fresh water for plant makeup. Effluent from a publicly owned treatment works (POTW, i.e., municipal wastewater treatment plant) has become an increasingly common alternative. These waters typically contain elevated concentrations of ammonia, nitrite/nitrate, organics, phosphate, surfactants, and suspended solids, all of which, if left untreated, can lead to serious microbiological fouling issues in cooling towers and cooling systems. This has led facilities to exploring new approaches to their wastewater treatment process.

Fouled cooling tower film fill

With proper pretreatment and cooling water chemical treatment, such supplies can successfully be utilized.

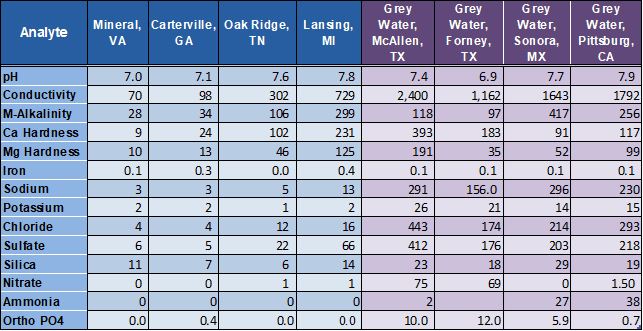

The table below outlines the primary constituents from several different water sources around the United States.

Table 1. Comparison of Several U.S. Waters

(Values apart from pH and conductivity are in units of mg/L)

Grey water (also known as treated wastewater effluent or reclaim water) contains higher concentrations of many impurities.

Approaches to the Wastewater Treatment Process

A common technique for initial wastewater treatment, basic clarification only removes suspended solids and some large organics. Aluminum- or iron-based coagulants precipitate phosphate, and can therefore be a useful form of basic clarification. Like other technologies, clarifier design has been significantly enhanced over the large, low-flow rate circular types that were ubiquitous during the last century. In systems such as the ballast type (typically micro-sand or magnetite), flow rates per clarifier capacity may be 10–20 times greater than in the old styles.

However, clarification does nothing to remove soluble nitrogen-based impurities, particularly ammonia and nitrite/nitrate. Many organics can also carry through a clarifier. Thus, even with clarification for suspended solids and phosphate removal, much food/nutrients can still enter the plant. Selecting biological processes for pretreatment as part of your wastewater treatment process may mitigate these issues.

Biological Methods for Wastewater Treatment

Facilities have utilized biological methods in wastewater treatment processes for many years. One very common approach is the activated sludge process, in which the waste stream flows into a large basin or basins filled with beneficial microorganisms that consume the organics and nitrogen/phosphorus nutrients. The term “activated” refers to the air injected into pond volume, often at numerous locations, to provide an aerobic environment for the microbes. This transforms the soluble material in new cells that can be removed as suspended solids. A common variation on this technology is the trickling filter, in which the wastewater flows over the fixed media to which the organisms are attached, providing a stable base for the microbes to carry out waste removal.

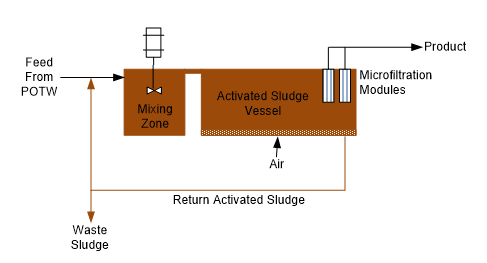

A difficulty with these technologies is that the treatment processes are slow and require large pond volumes or media surface area. Two other technologies have emerged as leading alternatives: membrane bioreactors (MBR) and moving-bed bioreactors (MBBR). The schematic below outlines the MBR setup.

The Benefits of Membrane and Moving-Bed Bioreactors

Essentially an enhanced activated sludge process, MBR consists of beneficial microorganisms consuming the food and nutrients that enter the main vessel via the mixing zone. A recycle stream helps bring active, well-established organisms to the inlet of the mixing zone. Unlike conventional activated sludge, MBR uses ultrafilter membranes rather than a traditional clarifier to separate solids from the effluent.

The microfiltration process produces a very clear stream, essentially free of suspended solids. One deficiency of this most basic MBR process is that ammonia in the stream is converted to nitrite/nitrate, but the nitrogen remains. Thus, nitrogen can still serve as a nutrient in the plant cooling water system. Expanding the MBR system to include anoxic reaction chambers may solve this problem, as this will promote denitrification, where microorganisms can convert nitrite/nitrate to elemental nitrogen.

With MBBR, the main reaction vessel includes mobile plastic media that serve as sites for the beneficial microorganisms to attach and then consume the nutrients and food from the influent. Because the reaction vessel is agitated with mechanical stirrers, settling, flotation, or filtration must be external to the vessel.

How ChemTreat Can Help

ChemTreat representatives can help plant personnel evaluate chemical requirements for the wastewater treatment process options outlined above. They can also recommend programs for the cooling and process systems fed with the resultant makeup water. Future blog posts will discuss methods to treat wastewater streams generated within the plant.

Please contact ChemTreat for assistance in designing a treatment program customized for your application. As with all other technologies, due diligence is necessary to determine the feasibility for utilizing these methods. Always consult your equipment manuals and guides.