Consistent makeup water purity is an absolute necessity in the beverage industry. Consumers demand consistency, and without it, a company may see sales and revenue drop.

An increasingly popular method to produce consistent makeup is micro- or ultrafiltration (MF and UF) of incoming plant service water followed by reverse osmosis (RO). With modern membrane technology, even the most basic RO can remove 99% or more dissolved ions from water. RO is a mature process, but proper RO pretreatment to prevent particulate and microbiological fouling and scale formation is very important for system reliability.

The Benefits of Reverse Osmosis for Makeup Water Treatment

The potential application of RO as a makeup water treatment method became well known in the last century and became popular with the development of and improvements upon spiral-wound membrane technology.

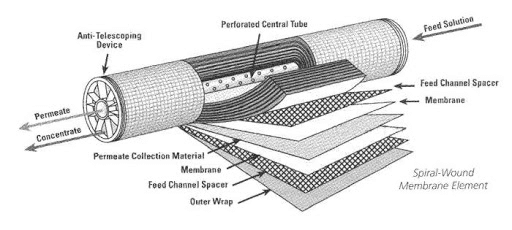

Figure 1. Cutaway view of a spiral-wound RO membrane. This Photo by Unknown Author is licensed under CC BY-NC

A flat membrane sheet has as a backbone of several layers, which are all wrapped around a central, perforated plastic core. Feedwater enters the front end of each element and flows along the feedwater carrier, while pressure pushes water through the membrane. The purified water, known as permeate, flows to the central core, and the increasingly concentrated feedwater (reject) exits the element.

Each RO pressure vessel typically has several elements arranged in a series. The basic RO system is a two-stage, single-pass type.

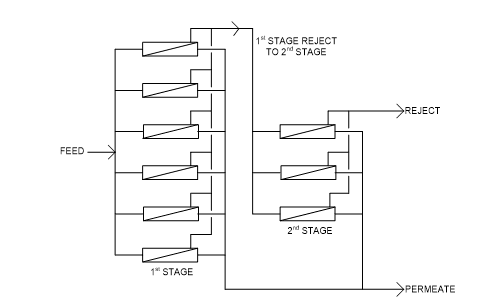

Figure 2. General schematic of a two-stage, single-pass RO

A critical feature of RO is illustrated in this diagram. With “normal” feedwaters, approximately 50% of the influent is converted to permeate in the first stage. This means that without further processing, 50% of the feedwater would be wasted. In the common two-stage design, first-stage reject is routed through additional pressure vessels in the second stage increasing total water recovery to 75%.

RO membranes, especially the lead elements, are susceptible to particulate fouling. Usually, 5- micron depth filters are placed ahead of the RO to minimize the potential for particulate fouling; however, micro- or ultrafiltration pretreatment of RO feedwater is becoming more common. Micron- or ultrafiltration can remove particles down to 0.1-microns or less.

Scale formation is another issue to be considered. When water flows through an RO pressure vessel, dissolved solids increase in concentration from inlet to outlet and may reach the salt saturation point. Potential deposits include calcium carbonate. sulfate, silica and alkaline metal silicates, strontium sulfate, barium sulfate, and calcium fluoride. Thus, feeding antiscalant is typical treatment for reverse osmosis systems. Common antiscalants include polyacrylates and phosphonates.

Pretreatment chemicals can affect membrane performance. Coagulating agents of the cationic variety, most notably, aluminum compounds, are particularly troublesome to RO membranes. Chlorine (usually fed as bleach) injected into the primary plant makeup to control microbiological fouling will react with nitrogen-carbon bond in the RO membrane and irreversibly damage it. This is oxidative attack. Chlorine should be removed upstream of the RO, but the absence of any biocides leaves the membranes in danger of microbial attack.

Figure 4. Severe microbiological fouling evident at the inlet end of an RO membrane. Photo by Brad Buecker, ChemTreat.

Biological fouling can cause irreversible damage to membranes because the deposits cannot be completely removed by standard cleaning methods. One technique to minimize fouling is periodic (treatment frequency depends on the fouling potential) of a nonoxidizing biocide. A popular choice is dibromo-nitrilo-propionamide (DBNPA).

A typical two-stage, single-pass RO system recovers approximately 75 percent of the inlet feed and produces a waste stream (reject) of the remaining 25 percent. This stream must be disposed of. For plants with cooling towers, the tower basin is often an ideal location for the reject. However, tower blowdown still represents a wastewater stream that may need treatment before discharge. This is yet another example that illustrates how water use and wastewater discharge must be viewed holistically in beverage plant operations.

Please contact ChemTreat for assistance in designing a treatment program customized for your application. Like all other technologies, due diligence is necessary to determine the feasibility for utilizing methods. Always consult your equipment manuals and guides.